Single-phase motor

A single-phase motor and rotor technology, applied to synchronous motors with static armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit static components, etc., can solve the problem of motor efficiency reduction, motor torque ripple It can improve the output, reduce the torque ripple, and ensure the starting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, a single-phase motor as an embodiment will be described with reference to the drawings. The embodiments shown below are merely examples, and it is not meant to exclude the application of various modifications and techniques not explicitly described in the following embodiments. Each structure of this embodiment can be implemented with various modifications within the range which does not deviate from the gist. In addition, they can be selected according to need, or can be combined appropriately.

[0036] (structure)

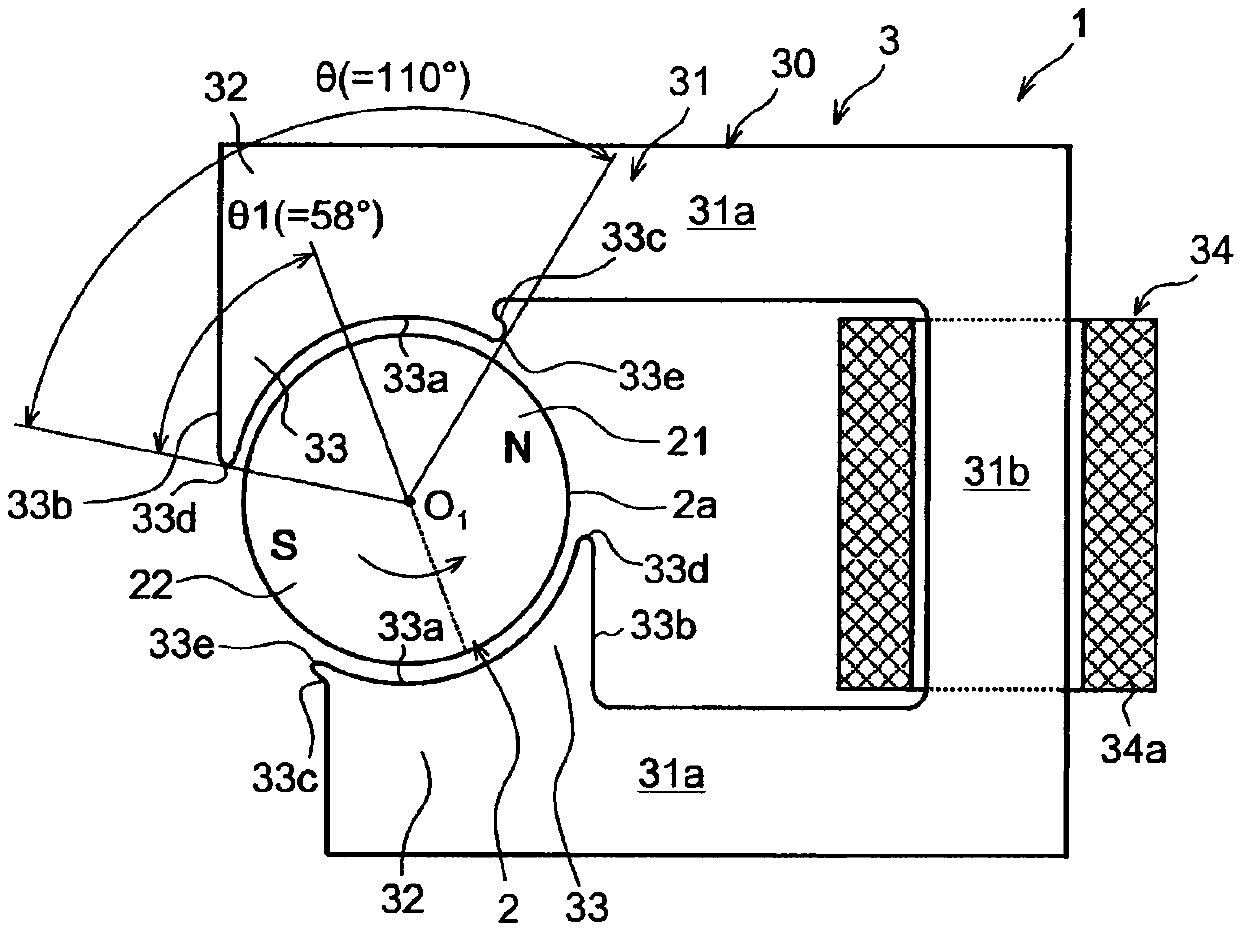

[0037] like figure 1 As shown, this single-phase motor (hereinafter simply referred to as a motor) 1 is an inner-rotor type two-pole two-slot single-phase brushless motor having a rotor 2 arranged inside and a stator 3 arranged outside.

[0038] The rotor 2 has permanent magnets, and N poles 21 and S poles 22 are arranged on the outer periphery of the rotor 2 with a phase shift of 180 degrees. The rotor 2 revolves around the center of rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com