Sealing water cooling structure for motor shell

A motor casing and water-cooling technology, which is applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of complex structure of the outer water jacket, easy damage of the sealing ring, and difficult casting, so as to prevent The effect of motor leakage failure, ensuring sealing reliability and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

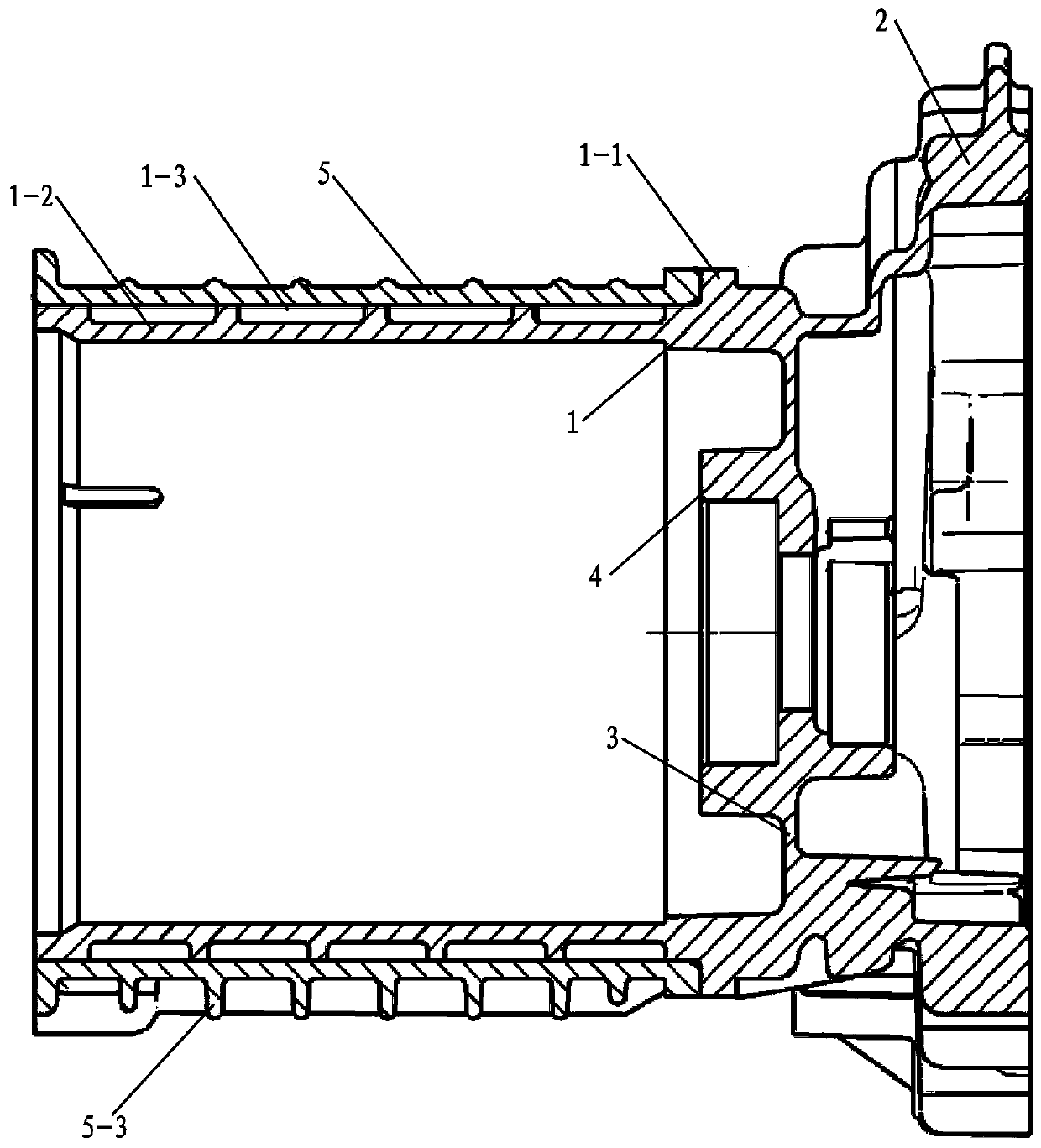

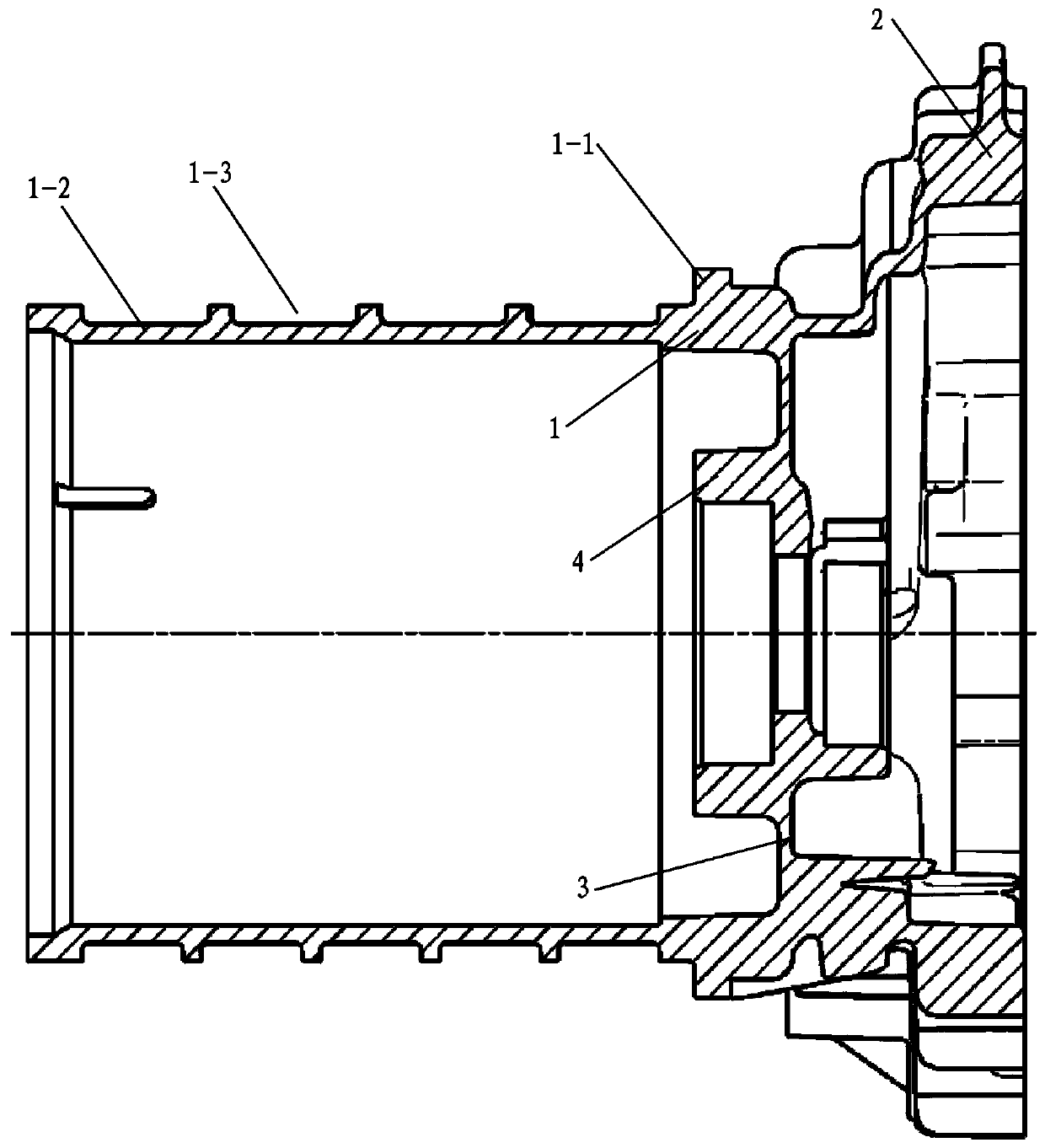

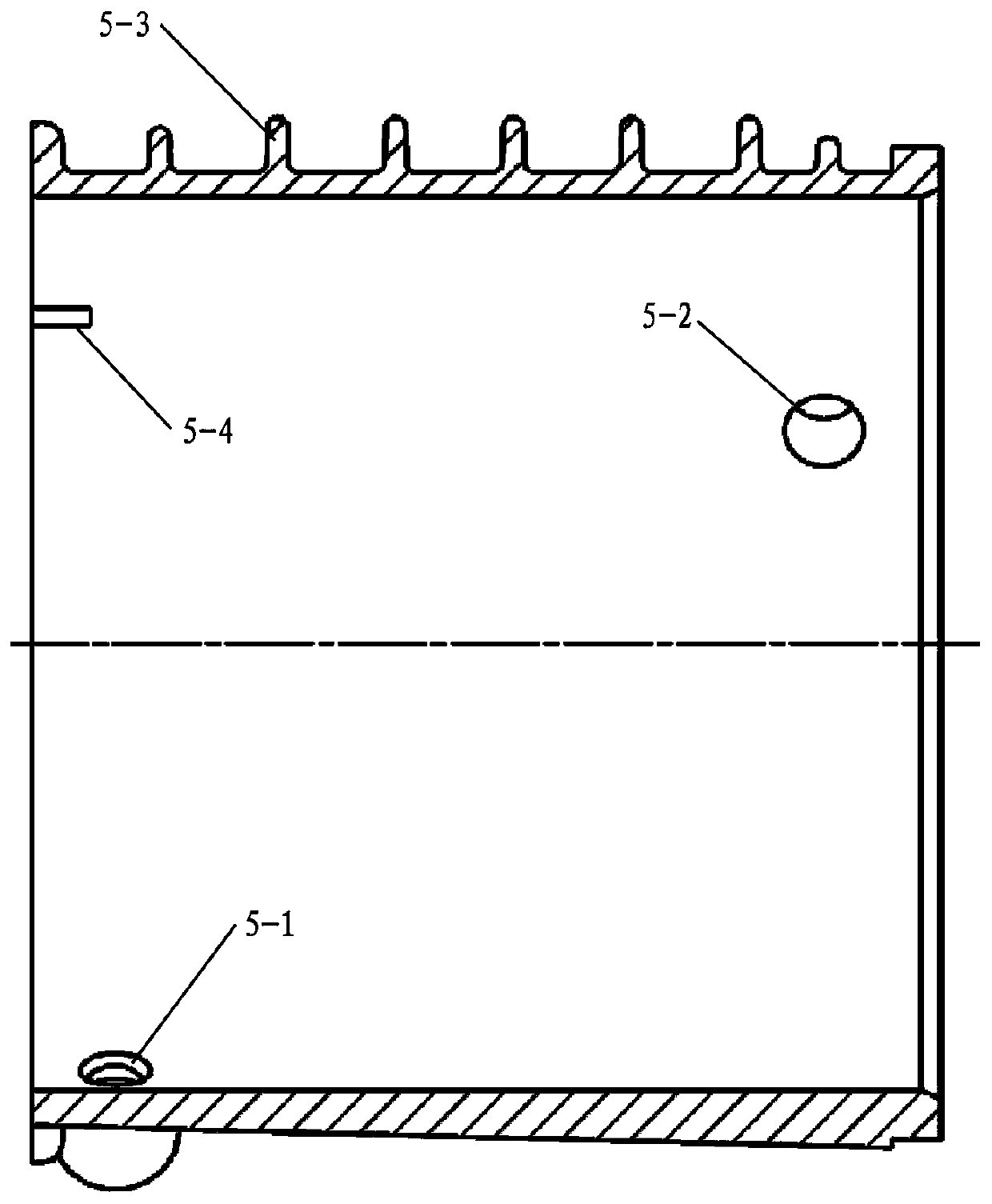

[0015] see Figure 1 to Figure 3 , a motor housing sealed water-cooled structure, including an integrally formed housing with a reducer case part 2 and a motor case part 1, and a partition wall provided between the motor case part 1 and the reducer case part 2 3, the partition wall 3 is provided with a motor front bearing seat 4, so that the reducer and the motor share one end face, which can not only reduce the axial length of the system assembly, make the internal structure of the system more compact, but also improve the system NVH performance. One end of the motor box part 1 adjacent to the reducer box part 2 is provided with an outwardly protruding positioning flange 1-1, and the positioning flange 1-1 is separated from the circumference of the motor box part 1 at the mouth end of the motor box part 1. The outer wall section is the waterway setting part 1-2, the outer surface of the waterway setting part 1-2 is provided with a spiral waterway groove 1-3 around the circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com