Low-pressure casting hole porosity defect calculation method

A calculation method and low-pressure casting technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve problems such as the increase of the critical solid fraction of molten metal and the inability to achieve accurate calculation of porosity defects in low-pressure casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

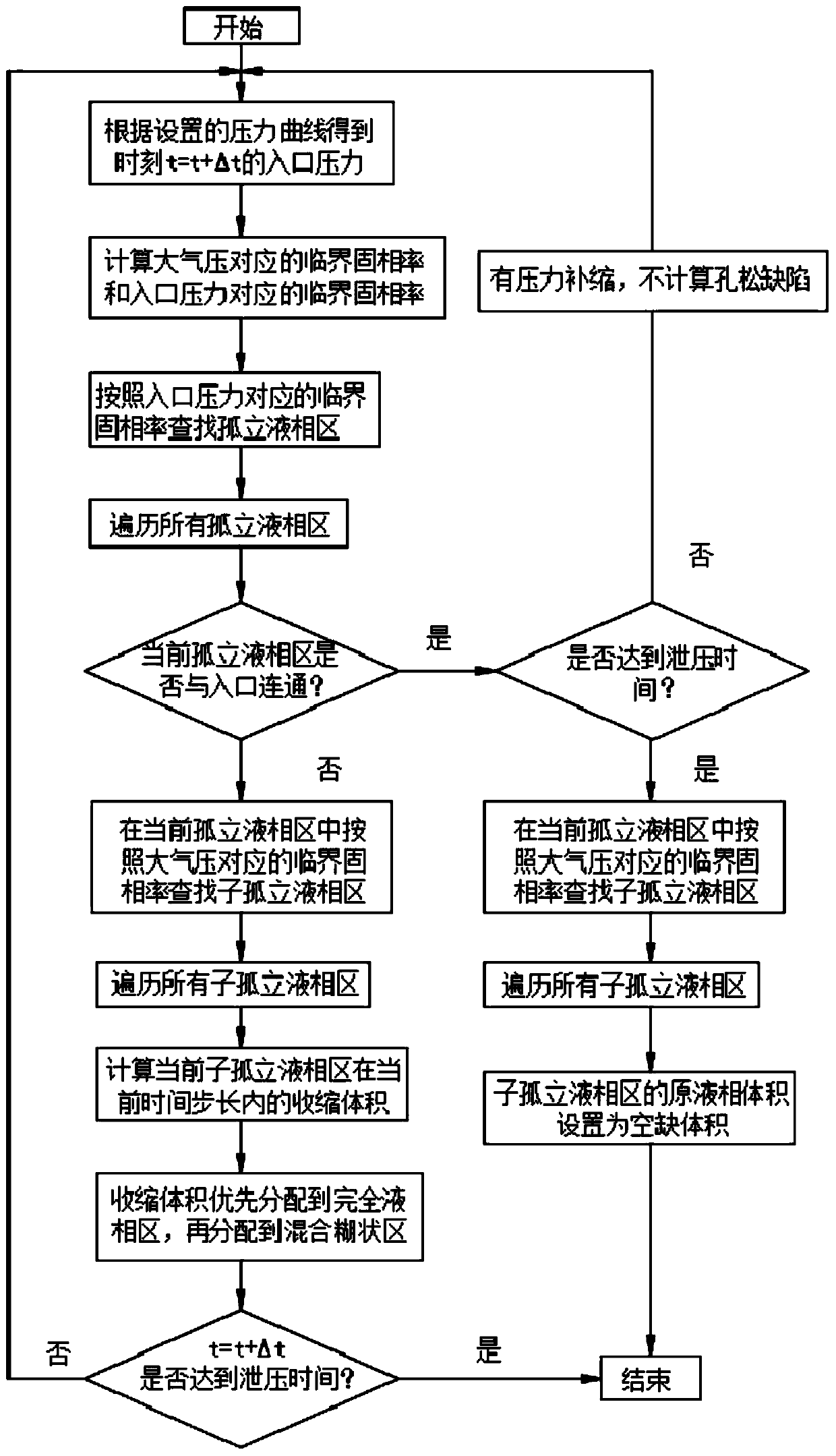

[0039] Such as figure 1 As shown, this embodiment provides a method for calculating porosity defects in low-pressure casting, which includes the following steps:

[0040] S1. Construct a three-dimensional model of the gating system, initialize the gating system at the beginning of solidification, and the initialization process includes setting the inlet pressure curve;

[0041] S2. Obtain the inlet pressure at time t=t+Δt according to the set pressure curve; specifically, the setting of the pressure curve needs to take into account the filling and pressurizing stage to ensure that the liquid level does not drop and the casting can crust under a small pressure , to avoid the surface of the casting being too rough during the pressure holding and boosting stage when the mold material is a sand mold; pressurizing on the basis of filling and boosti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com