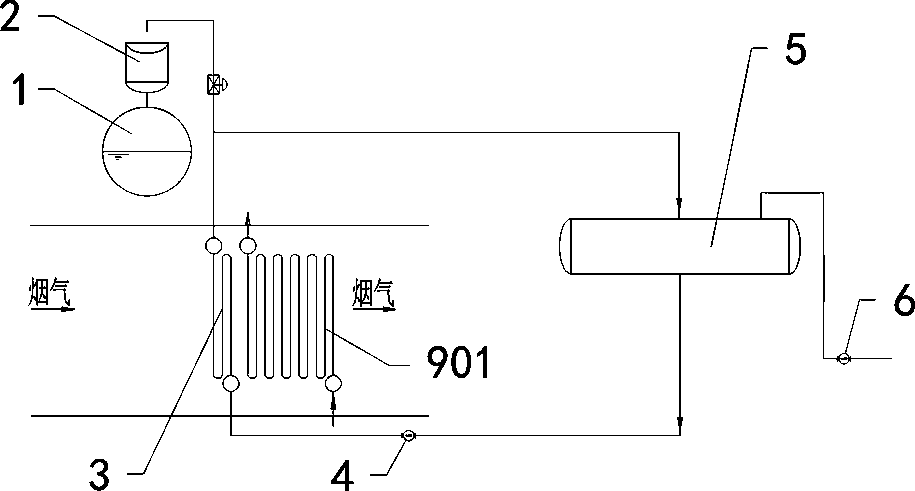

Waste heat boiler tail deoxidizing heat supply system

A waste heat boiler and heating system technology, applied in chemical instruments and methods, liquid degassing, separation methods, etc., can solve the problems of easy corrosion of the heating surface of the hot water supply, the decrease of the energy efficiency of the boiler operation, and the safety hazards of the unit, etc., to achieve Boiler output and operation with high energy efficiency, reasonable structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

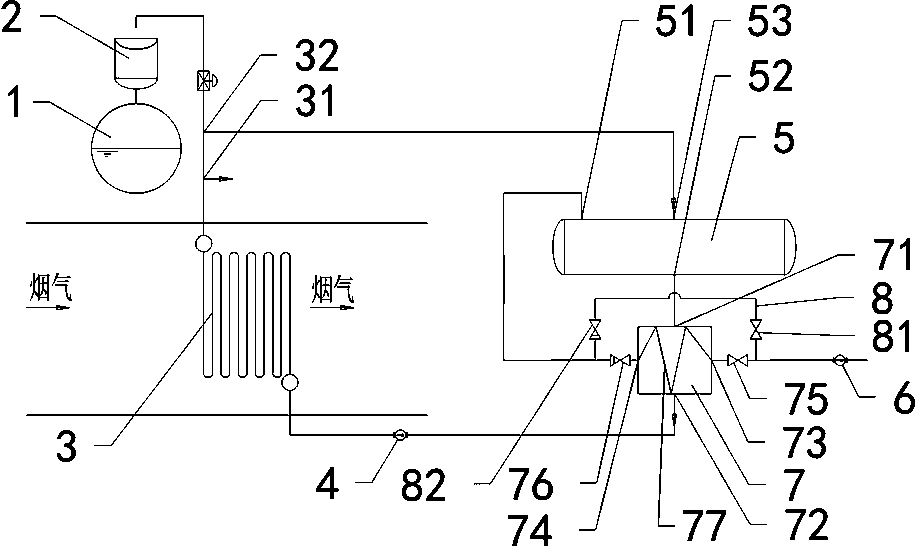

Embodiment 1

[0019] Embodiment 1: as attached figure 2 , shown, the present invention comprises steam drum 1, the deoxygenation head 2 that outlet is connected with steam drum 1, the tail heating surface 3 that outlet is connected with deoxygenation head 2 inlets, the second feed water pump 4, has feed water inlet 51, feed water Atmospheric deaerator 5 with outlet 52, deoxygenation and hot water supply inlet 53, the first feed water pump 6, the inlet of the tail heating surface 3 is connected with the outlet of the second feed water pump 4, and the outlet end of the tail heating surface 3 is provided with a hot water supply Outlet 31 and deoxygenated hot water supply outlet 32, deoxygenated hot water supply outlet 32 is connected with deoxygenated hot water supply inlet 53, also includes water-water heat exchanger 7, water-water heat exchanger 7 has and feedwater outlet 52 connected to the second feedwater inlet 71, the second feedwater outlet 72 connected to the inlet of the second fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com