Carbon-ceramic axle-mounted brake disc suitable for high speed trains

A high-speed EMU, brake disc technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of bolt fatigue fracture, difficult to withstand high braking pressure and braking torque, axial force drop and other problems , to achieve the effect of improving service life and ensuring long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

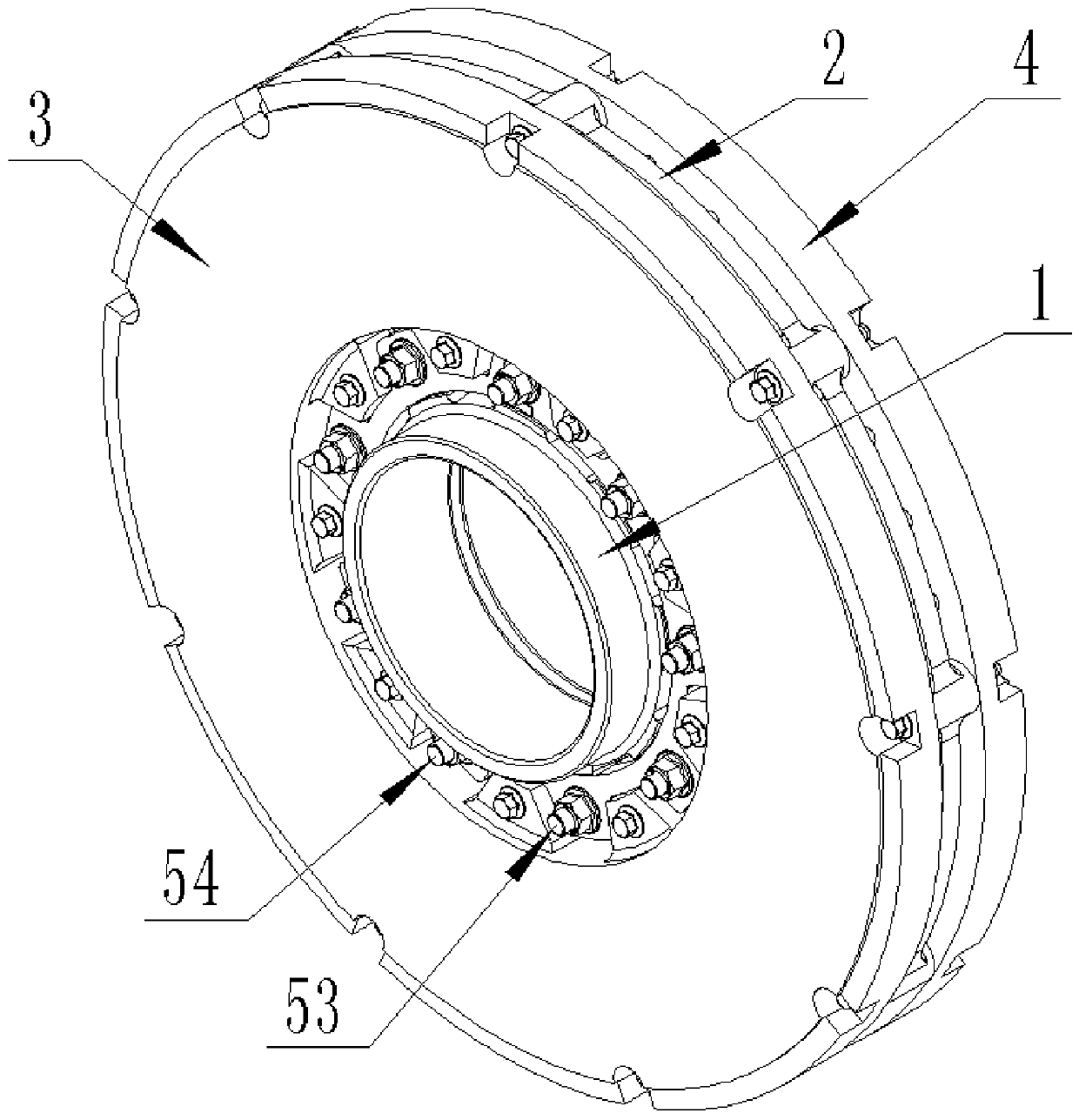

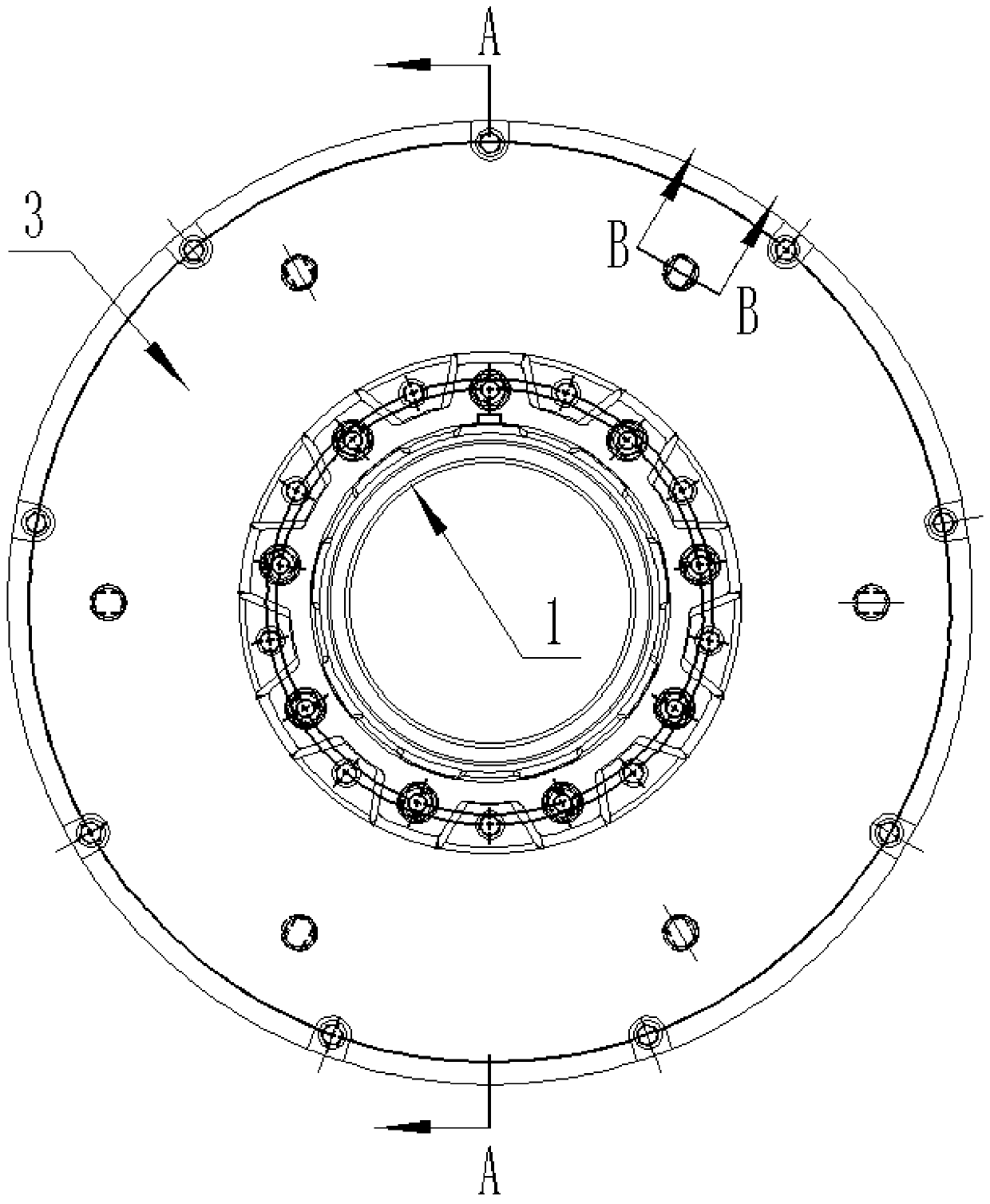

[0040] A carbon-ceramic axle-mounted brake disc suitable for high-speed EMUs, comprising a disc hub 1, an isolation support body 2, a first carbon-ceramic friction body 3, a second carbon-ceramic friction body 4 and a fixed outer sleeve of the disc hub 1 are provided. The pressure ring 5, the isolation support body 2, the first carbon ceramic friction body 3, the second carbon ceramic friction body 4 and the pressure ring 5 are all annular, the first carbon ceramic friction body 3, the isolation support body 2 and the second carbon ceramic friction body 3. The ceramic friction body 4 is along the axis of the hub 1 ( image 3 The dashed-dotted line in the middle is stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com