Floor tile laying structure

A pavement and brick technology, which is applied in the direction of building structure, floor, building, etc., can solve the problems of stress superposition and concentration, arching and falling off, plate hollowing, etc., to suppress expansion and contraction stress, prevent plate hollowing, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

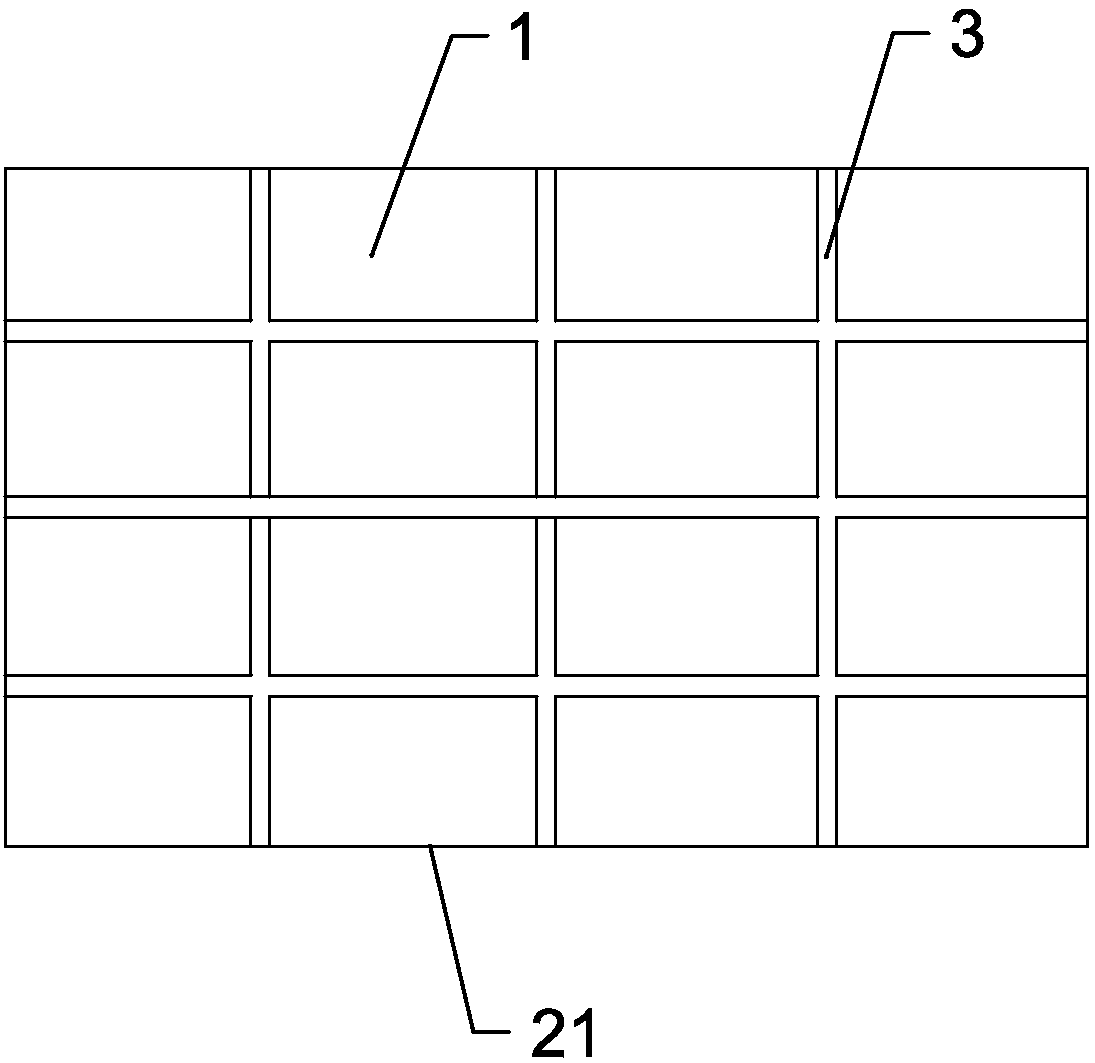

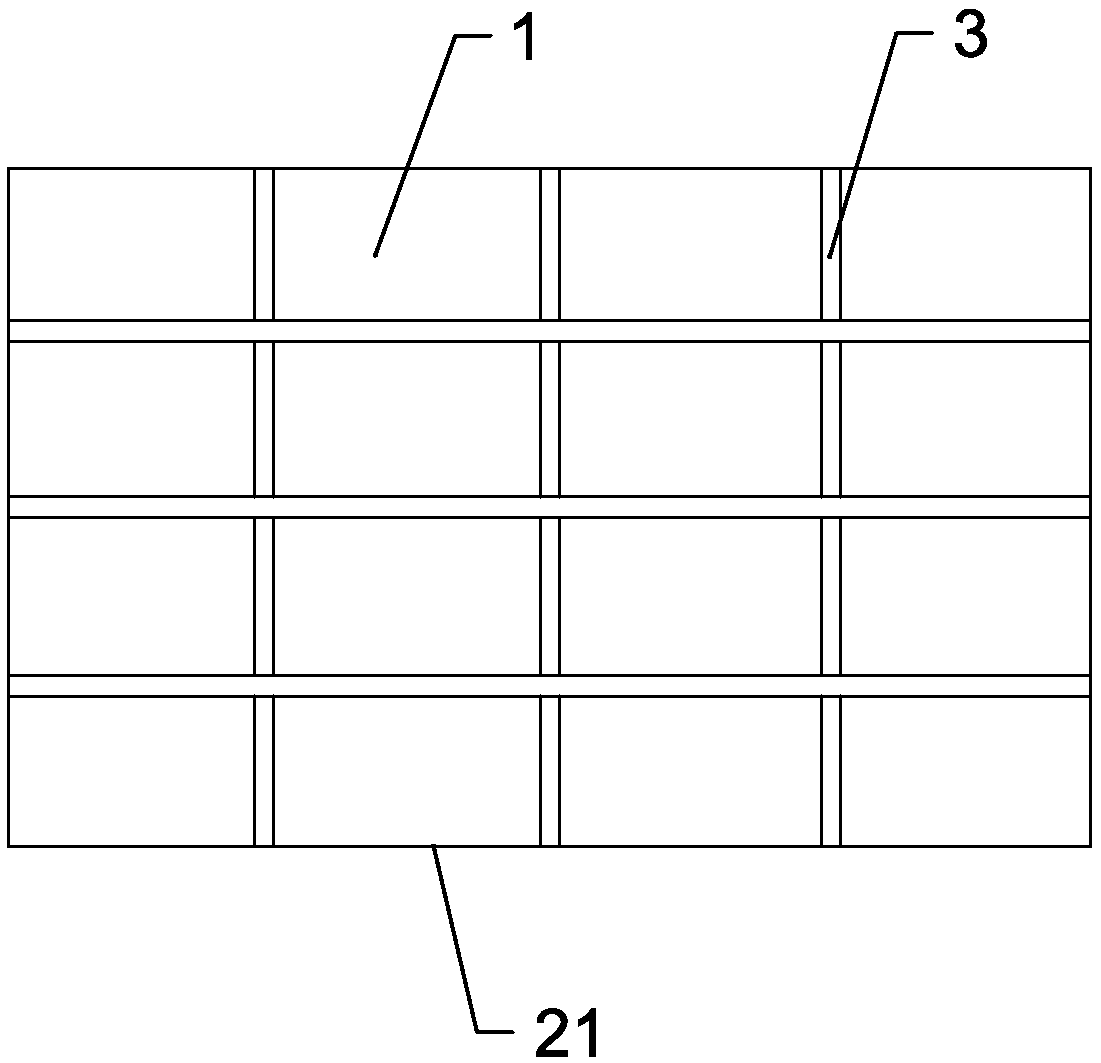

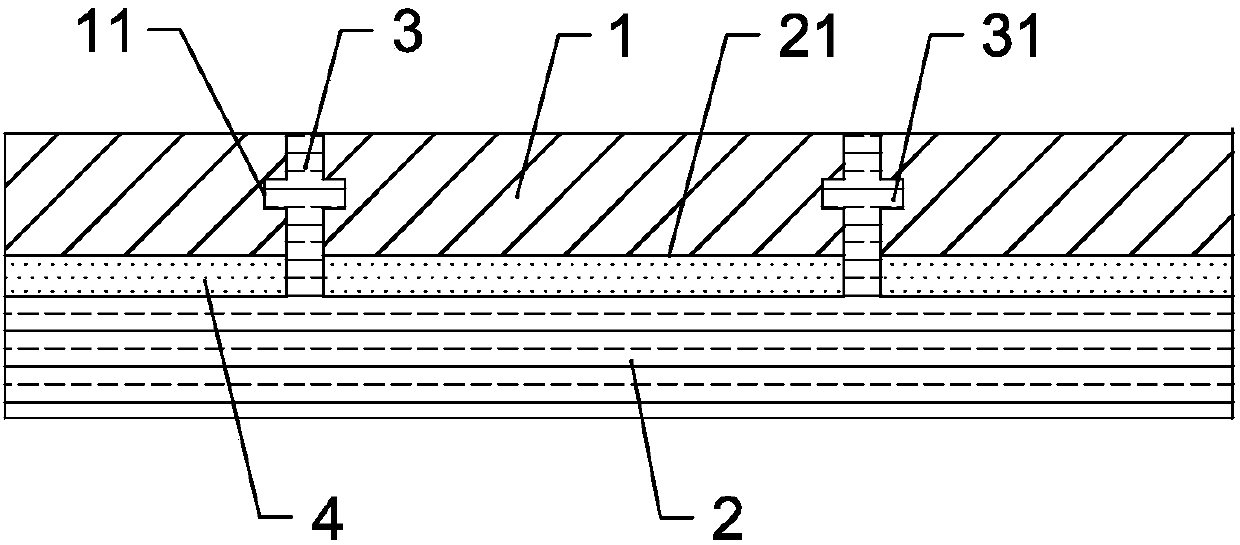

[0021] Such as figure 1 with figure 2 As shown, a slab paving structure includes a slab 1 and a paving mat 2. The paving mat 2 is provided with a grid 21 separated by a partition 3 and adapted to accommodate the slab 1. A convex rib 31 is provided on the side wall of the plate 3, and a groove 11 is provided on the side wall of the plate brick 1 corresponding to the convex rib 31 with a groove 11 that engages with the convex rib 31. Further, a buffer layer 4 is provided between the slab 1 and the paving mat 2. The paving mat 2 and the partition 3 are made of wood, alloy, plastic, rubber, composite board or plastic steel profile.

[0022] The slab-brick paving structure of this technical scheme discards the tradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com