Straw wall-breaking pulping machine and straw wall-breaking pulping method

A technology of pulping machine and straw, which is applied in fermentation, gas production bioreactor and other directions, can solve the problems of labor and time-consuming, pollute the environment, destroy straw, etc., and achieve the effects of increasing biogas production, significant economic benefits, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

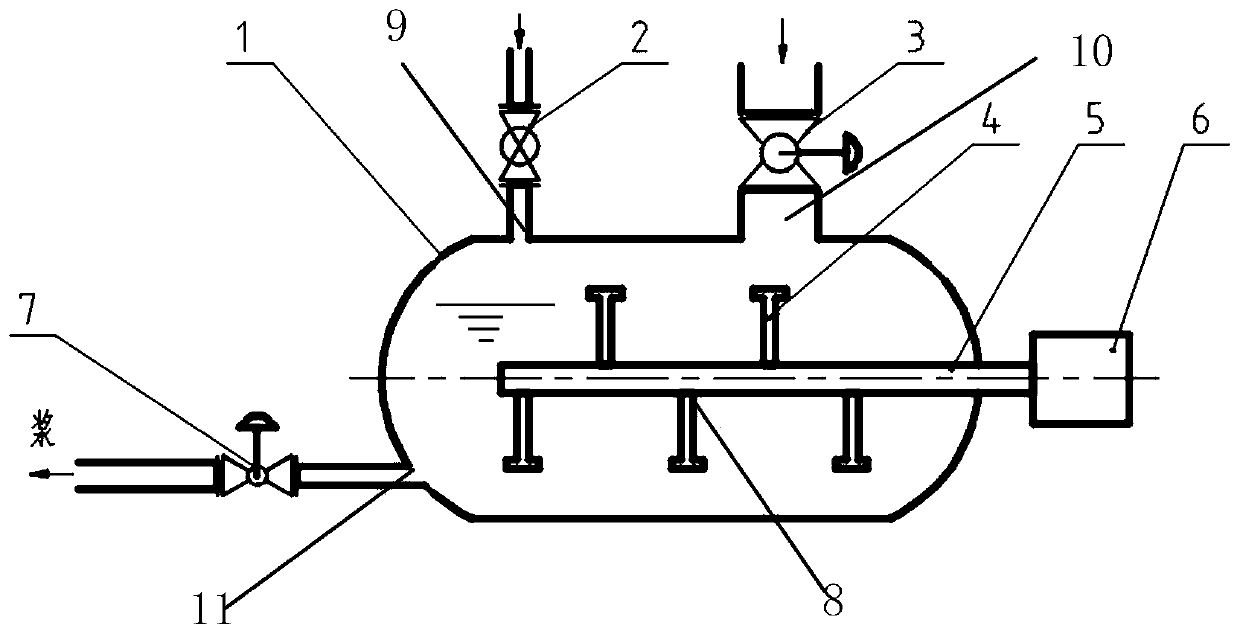

[0029] The invention provides a straw wall breaking pulper, see Figure 1-2 , including a barrel 1 and a number of stirring devices 8 uniformly arranged inside the barrel body, a steam inlet 9 and a feed port 10 are arranged on the top of the barrel body 1, and a slurry outlet 11 is arranged at the lower end of the barrel body 1;

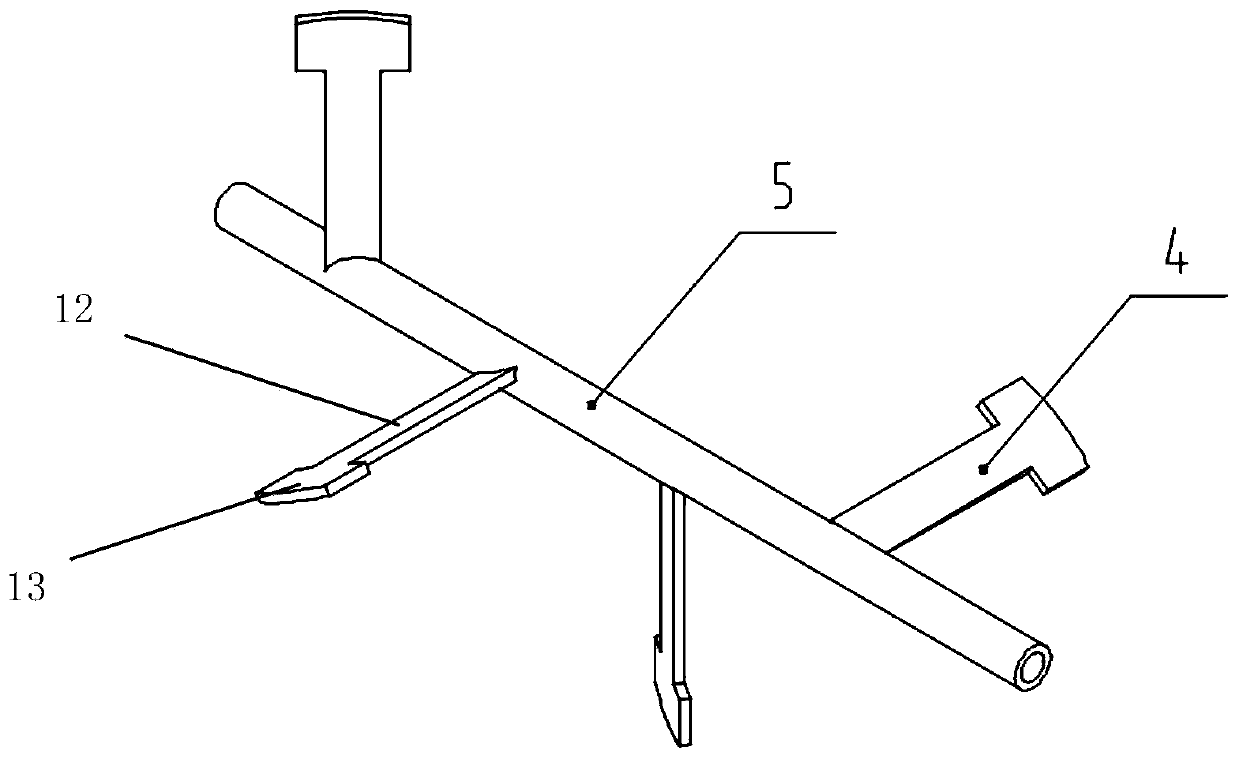

[0030] The stirring device 8 comprises a stirring shaft 5 and the stirring blades 4 evenly distributed on the stirring shaft 5;

[0031] Stirring blade 4 comprises the connecting arm 12 that is fixedly connected with stirring shaft 5 and the stirring sheet 13 that is arranged on connecting arm 12 ends; The length of stirring sheet 13 is greater than the width of connecting arm 12.

[0032] In the present invention, the raw materials are transported into the barrel, and through the blasting effect of the steam, the pulping of the straw wall is quickly realized; at the same time, the raw materials in the system are always in a fully closed state, whic...

Embodiment 2

[0039] A method for straw wall breaking pulping, using the above-mentioned straw wall breaking pulping machine; the specific steps are:

[0040] (1) Mix the crushed dry straw and water evenly in a weight ratio of 1:1.5, wherein the length of the dry straw is 20-30mm;

[0041] (2) Close the stop valve and the discharge valve, open the feed valve, put the prepared raw materials in step (1) into the barrel, the filling amount is 70% of the total volume of the barrel, and start the rotary motor at the same time to feed the raw materials Stir, the stirring speed is 20rpm / min;

[0042] (3) Open the shut-off valve and pass in the superheated steam, the temperature of the superheated steam is 183°C-187°C until the pressure reaches 1.0MPa, then heat and hold the pressure for 10 minutes;

[0043] (4) Quickly open the discharge valve, and the material in the barrel becomes slurry, which is sprayed into the atmospheric pressure release tank.

Embodiment 3

[0045] A method for straw wall breaking pulping, using the above-mentioned straw wall breaking pulping machine; the specific steps are:

[0046] (1) Mix the crushed dry straw and water evenly in a weight ratio of 1:2, wherein the length of the dry straw is 20-30mm;

[0047] (2) Close the shut-off valve and the discharge valve, open the feed valve, put the prepared raw materials in step (1) into the barrel, the filling amount is 80% of the total volume of the barrel, and start the rotary motor at the same time to feed the raw materials Stir, the stirring speed is 50rpm / min;

[0048] (3) Open the shut-off valve and pass in the superheated steam, the temperature of the superheated steam is 183°C-187°C until the pressure reaches 1.1MPa, then heat and hold the pressure for 7 minutes;

[0049] (4) Quickly open the discharge valve, and the material in the barrel becomes slurry, which is sprayed into the atmospheric pressure release tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com