Cathode side gas humidity adjusting system and method for proton exchange membrane fuel cell

A fuel cell cathode and proton exchange membrane technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems affecting the output performance, reliability, durability, air humidity adjustment of fuel cell stack 5, excessive air humidity or Over-low and other problems, to avoid over-dry or over-humidity, improve reliability and durability, and improve output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

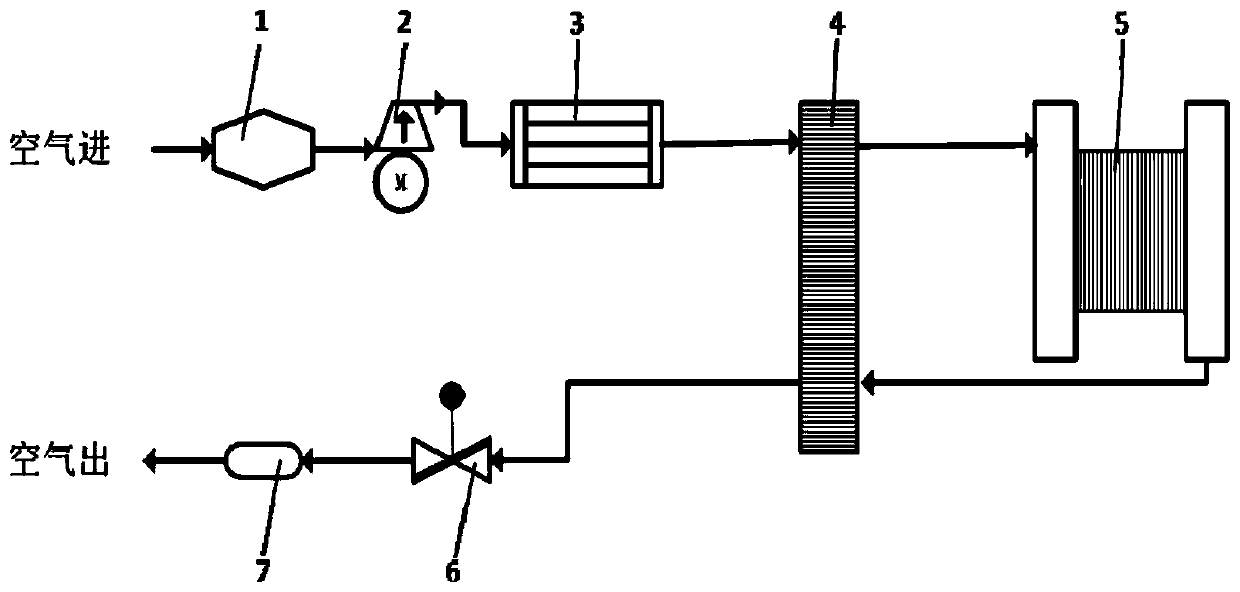

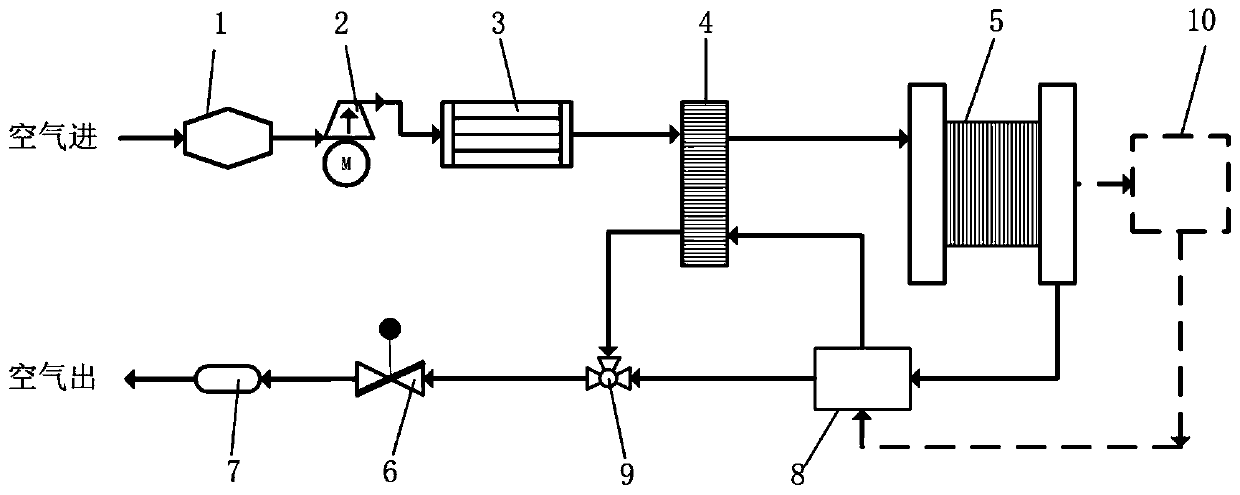

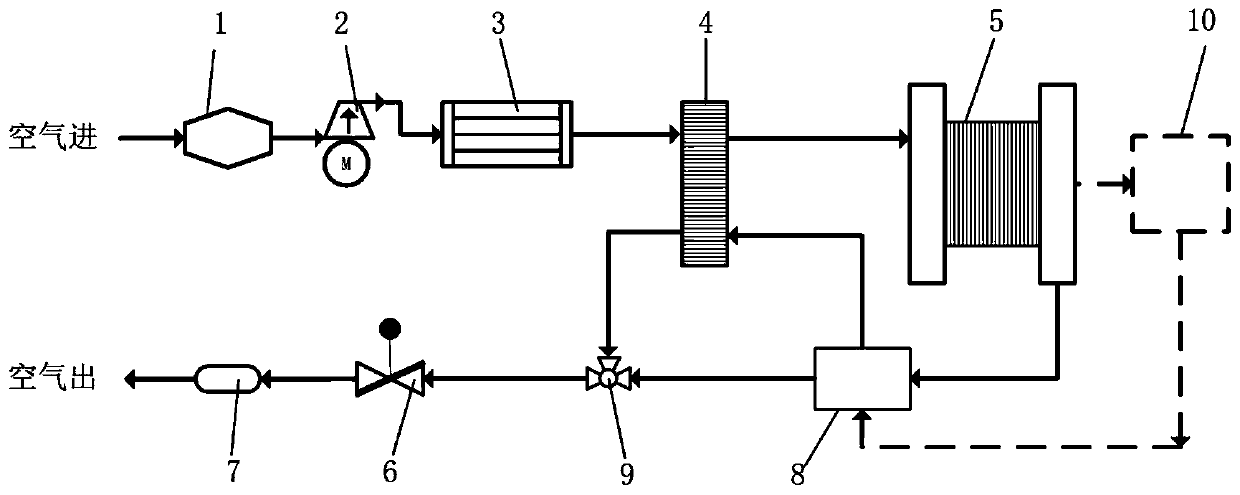

[0020] The proton exchange membrane fuel cell cathode side gas humidity adjustment system of the present invention comprises an air filter 1, an air compressor 2, an intercooler 3, an air humidifier 4, a fuel cell stack 5, an exhaust back pressure valve 6 and Exhaust processor 7, the outlet of air filter 1 is connected to the inlet of air compressor 2, the outlet of air compressor 2 is connected to the inlet of intercooler 3, the outlet of intercooler 3 is connected to the first inlet of air humidifier 4 The inlets are connected, the first outlet of the air humidifier 4 is connected with the inlet of the fuel cell stack 5, the outlet of the exhaust back pressure valve 6 is connected with the inlet of the exhaust processor 7;

[0021] It also includes a humidity regulator 8, a three-way valve 9 and a fuel cell control unit 10; the outlet of the fuel cell stack 5 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com