Power monitoring instrument batch production test system and method

A technology for production testing and power monitoring, applied in the direction of measuring electrical variables, instruments, measuring devices, etc., can solve problems such as simultaneous testing of power monitors, safety accidents, and voltage can not be short-circuited, etc., to achieve convenient tracking, Simple operation and clear results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

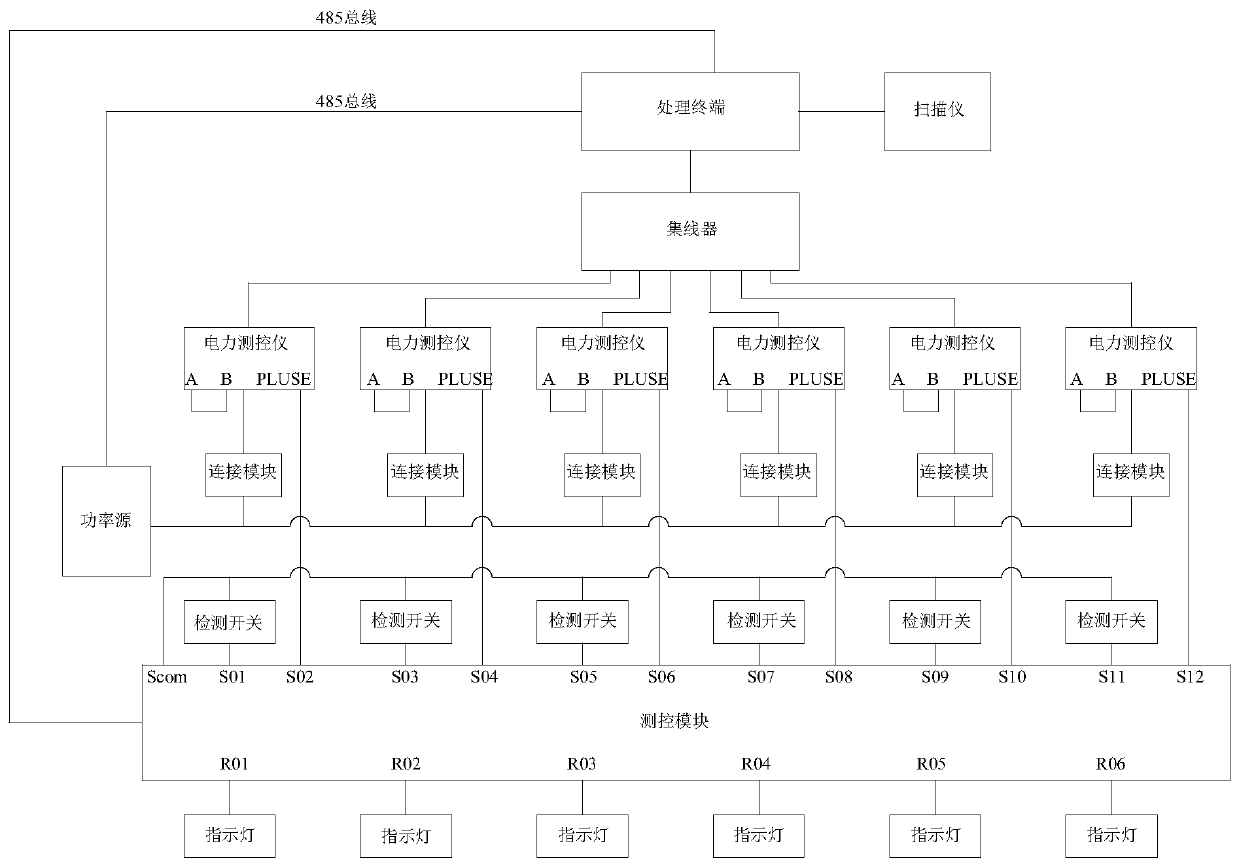

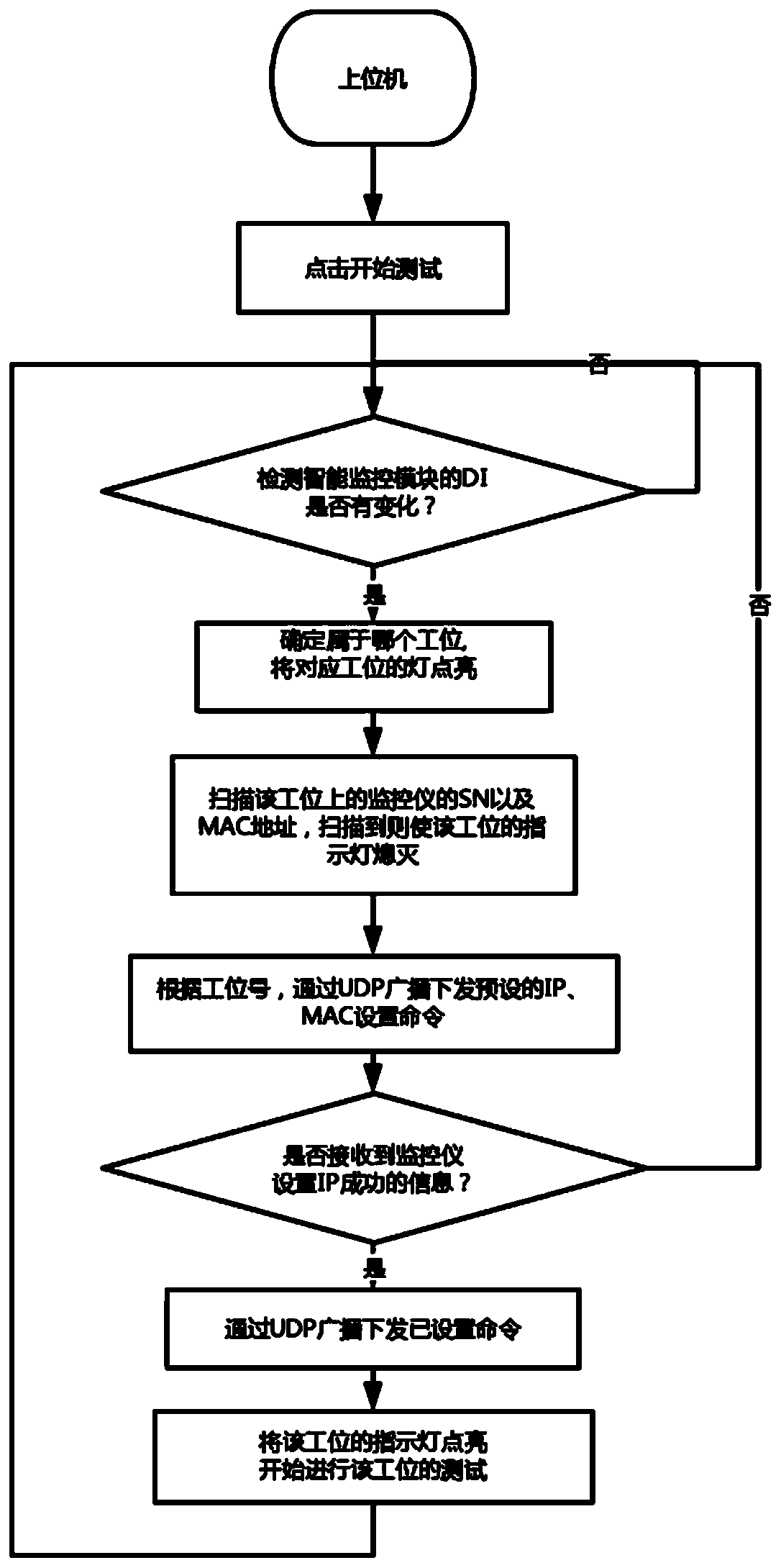

[0037] Please refer to figure 1 As shown, a mass production test system for power monitors can simultaneously test multiple power monitors at the same time. Measurement and control module, connection module, hub, scanner, detection switch and indicator light.

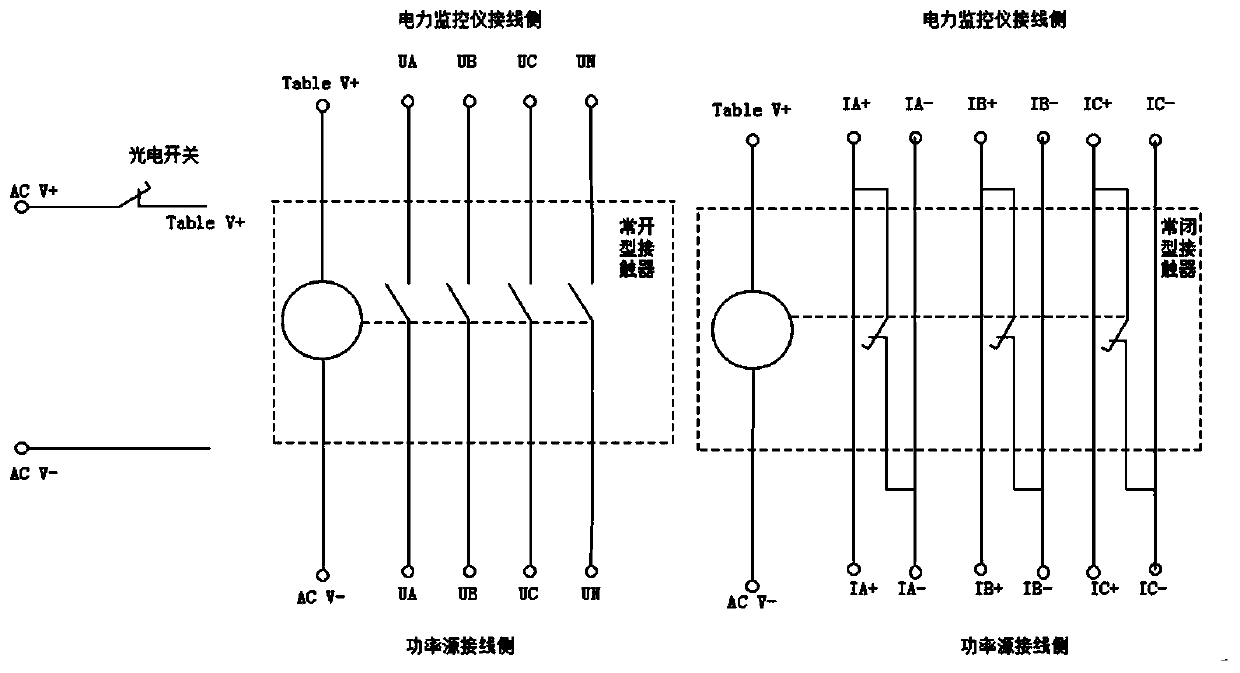

[0038]The power source is connected to the power measuring and controlling instrument through a connection module, and the power measuring and controlling instrument communicates with the processing terminal through a hub. Both the power source and the export module communicate with the processing terminal through a serial port (via RS485 bus), and the detecting One end of the switch is connected to the common terminal (Scom end) of the measurement and control module, the other end of the detection switch is connected to the DI interface of the measurement and control module, the indicator light is connected to the DO interface corresponding to the DI interface, and the scanner is connected to Handle the terminal.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com