Aeroelastic model of suspended monorail wind tunnel test pier stud

An aeroelasticity and wind tunnel test technology, which is applied in the field of rail transit, can solve problems such as the inability to satisfy the similarity principle between the scaled model and the prototype structure, affect the accuracy of the test results of the aeroelastic model, and change the structural parameters of the model. The test is true, accurate and reliable, the effect is good, and the effect of setting is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

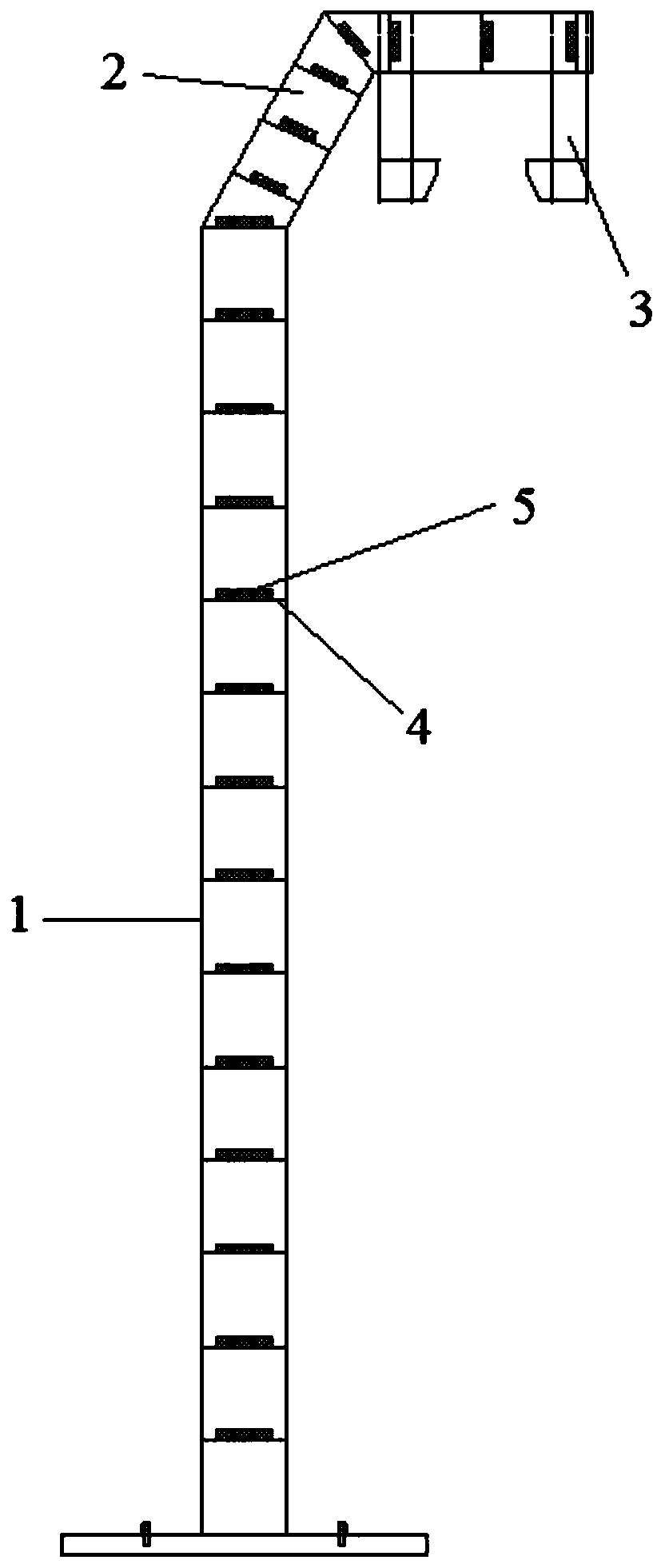

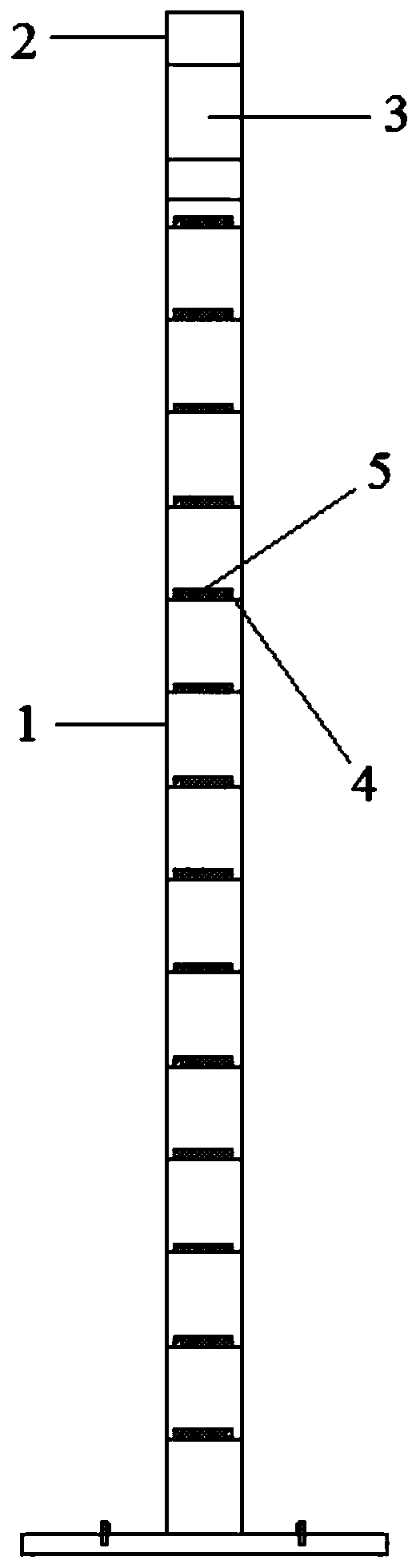

[0024] Such as Figure 1-3 As shown, the aeroelastic model of a suspended monorail wind tunnel test pier column according to the present invention includes a pier body 1 and a cantilever end 2 .

[0025] The cantilever end 2 is connected to the top of the pier body 1, and the cantilever end 2 is provided with a down-curved corbel 3. Both the pier body 1 and the cantilever end 2 are steel box structures, and the pier body 1 It includes four steel columns, the four steel columns are arranged in a rectangular shape, and steel plates are welded between two adjacent steel columns.

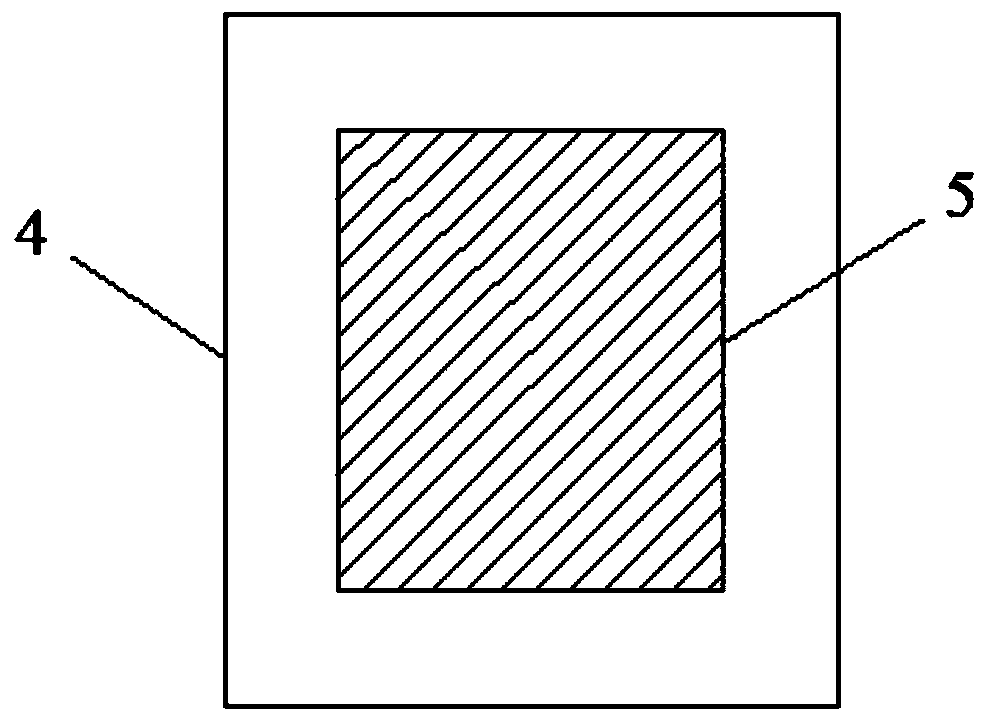

[0026] The pier body 1 and the cantilever end 2 are respectively provided with several steel partitions 4 at intervals along their respective length directions, and each steel partition 4 is welded to the corresponding pier body 1 or the cantilever end 2 Each of the steel partitions 4 is provided with a counterweight 5, and each of the counterweights 5 is bonded to the corresponding steel partition 4 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com