Online detecting device for dimension of vehicle hubcap cover hole

A technology for automobile hubs and testing equipment, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems that the measurement results are easily affected by human factors, the detection time cannot meet the production cycle, and the detection environment cannot meet the requirements. High-quality image requirements, reduce inspection costs, ensure production efficiency and the best effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

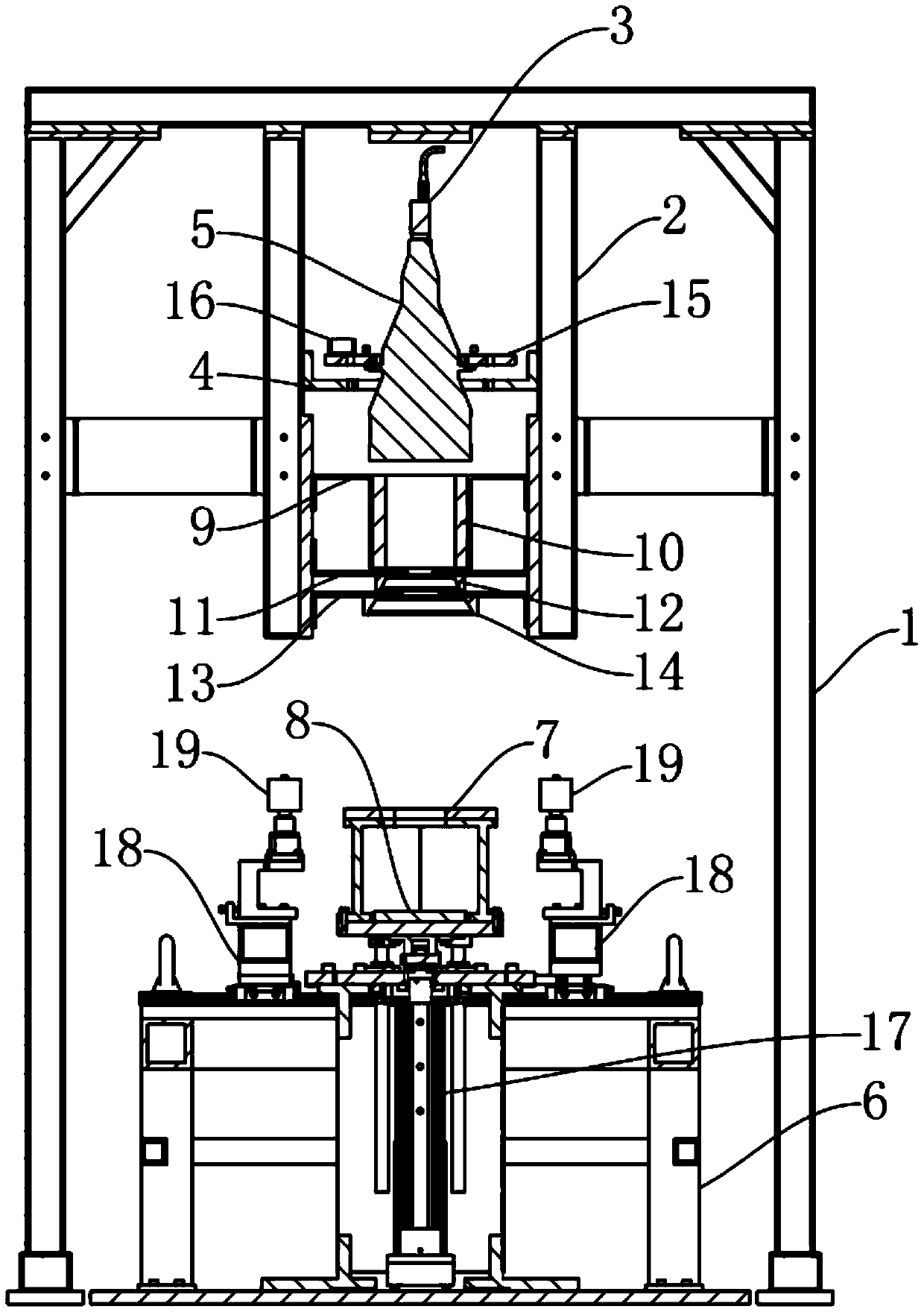

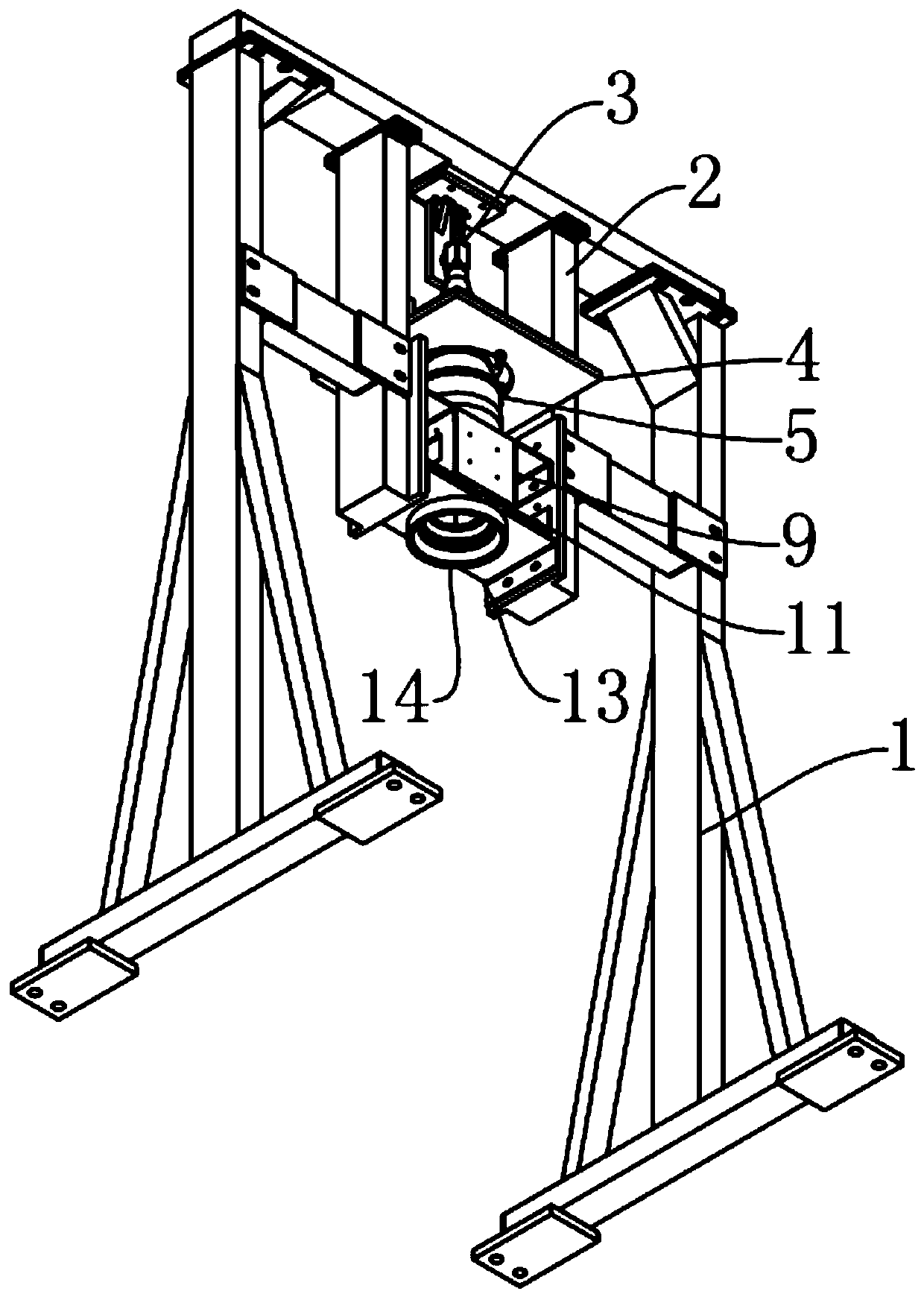

[0031] Such as figure 1 As shown, the embodiment of the present invention provides an on-line detection device for the hole size of the automobile hub cover, including a gantry 1, the top of the gantry 1 is provided with a downwardly extending installation frame 2, and an industrial camera 3 is installed on the installation frame 2 , the lens of the industrial camera 3 is connected to the telecentric lens 5, the telecentric lens 5 is installed on the mounting frame 2 through the lens mounting plate 4, the telecentric lens 5 is a standard component, and can be purchased and used by those skilled in the art. Obtain an image with a low distortion rate, improve the accuracy of size detection, and adapt to the size and structure of different hubs; the gantry 1 is provided with a mounting seat 6, and the mounting seat 6 is provided with a hub support frame 7, and the industrial camera 3 faces the hub support frame 7 , during detection, the hub is placed on the hub support frame 7, a...

Embodiment 2

[0037] The embodiment of the present invention provides an on-line detection device for the hole size of the automobile hub cover. Its structure is basically the same as that of the embodiment 1. The difference is that on the basis of the embodiment 1, the following improvements are made to further improve its performance :

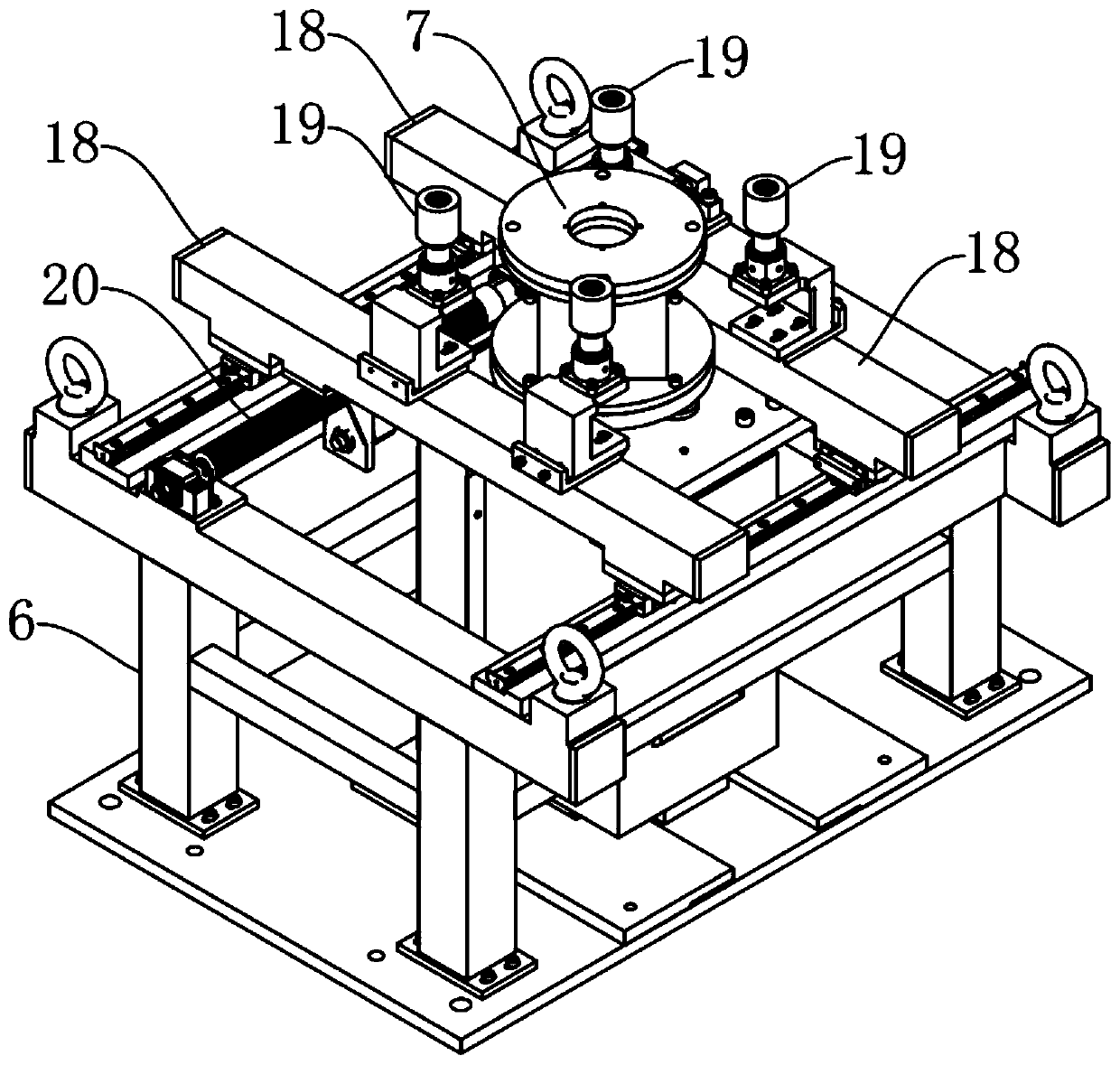

[0038] Mounting seat 6 is provided with linear drive mechanism, and linear drive mechanism connects wheel hub support frame 7, and here, linear drive mechanism is preferably electric cylinder 17, and the piston rod of electric cylinder 17 connects wheel hub support frame 7, and the cylinder block of electric cylinder 17 is fixed. Installed on the mounting base 6 , of course, those skilled in the art can also choose to use air cylinders or hydraulic cylinders, which will not be listed one by one here.

[0039] Because the linear drive mechanism is set to drive the hub support frame 7, when the wheels of different sizes and specifications are placed on the ...

Embodiment 3

[0041]The embodiment of the present invention provides an on-line detection device for the hole size of the automobile hub cover, the structure of which is basically the same as that of embodiment 2, the difference is that

[0042] A centering mechanism for aligning the center of the hub with the center of the hub support frame 7 is provided on the mounting base 6 . The centering mechanism includes two sliding beams 18 that are slidably installed on both sides of the hub support frame 7 through linear guide rails, and a double-headed screw 20 driven by a power device is installed on the mounting seat 6. The power device is preferably a servo motor. The screw threads at both ends of the screw 20 have opposite helical directions, and each sliding beam 18 is fixedly equipped with a nut that is compatible with the double-ended screw 20, so that when the double-ended screw 20 rotates, the two sliding beams 18 can be synchronously facing or opposite directions. Sliding can push the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com