Sealing structure

A technology of sealing structure and sliding buckle, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of damaged buckle structure, non-reusable, troublesome buckle structure disassembly, etc., and achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

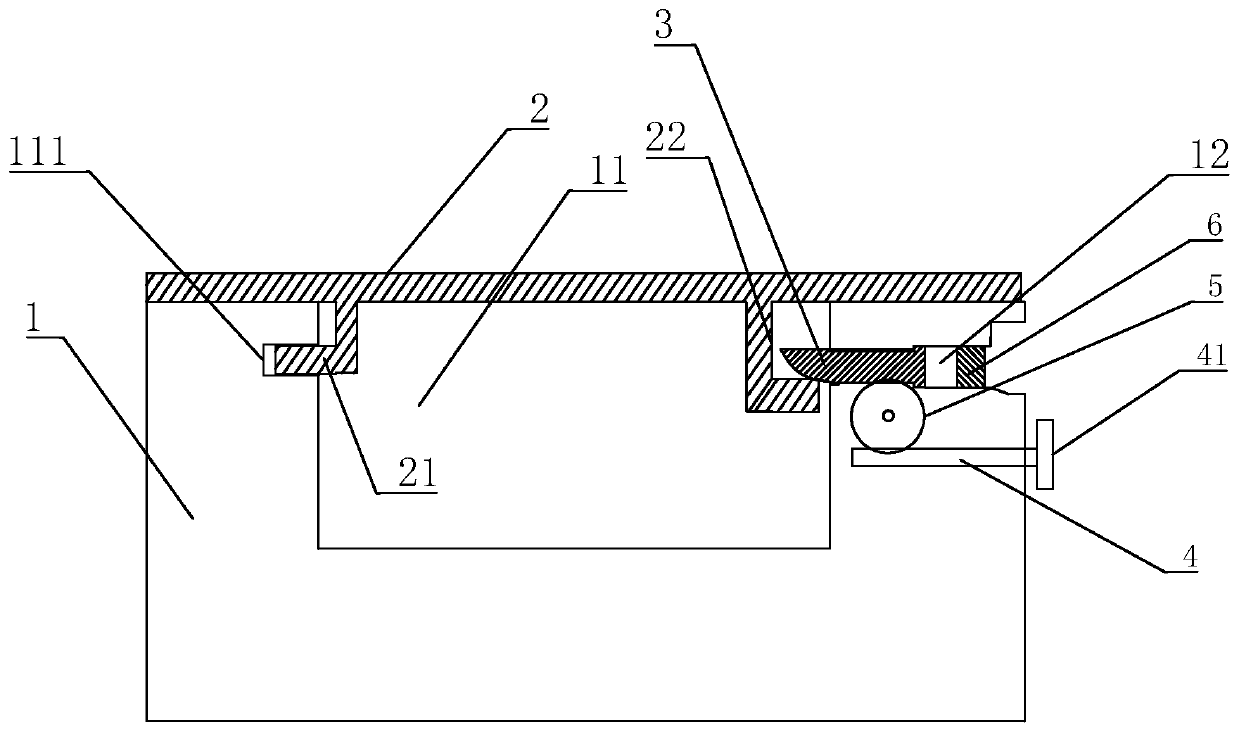

[0014] refer to figure 1 , a sealing structure of the present invention, comprising a containing body 1 and a cover body 2;

[0015] The containing body 1 is provided with an accommodating space 11 with an upper opening, and two opposite side walls of the accommodating space 11 are respectively provided with buckle grooves 111 and sliding button holes 12; the sliding button holes 12 are equipped with slidable The card strip 3. Specifically, the clamping strip 3 is loaded from the outside of the containing body 1 , the sliding button hole 12 is a through hole, and the outer end of the sliding button hole 12 is plugged with a sealing ring 6 . In order to prevent the clip bar 3 from moving unrestrictedly and falling out of the sliding button hole 12 and falling into the accommodation space 11 , the sliding button hole 12 is a stepped hole, and the clip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com