Small-sized steel plate bin having cone bottom without ring beam

A steel silo, small-scale technology, applied in the field of steel silos, can solve the problems of inconvenient disassembly, maintenance and use of steel silos, unclean grain discharge, and increased weight of steel silos, etc., to reduce the weight of the silo body and shorten the construction period , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

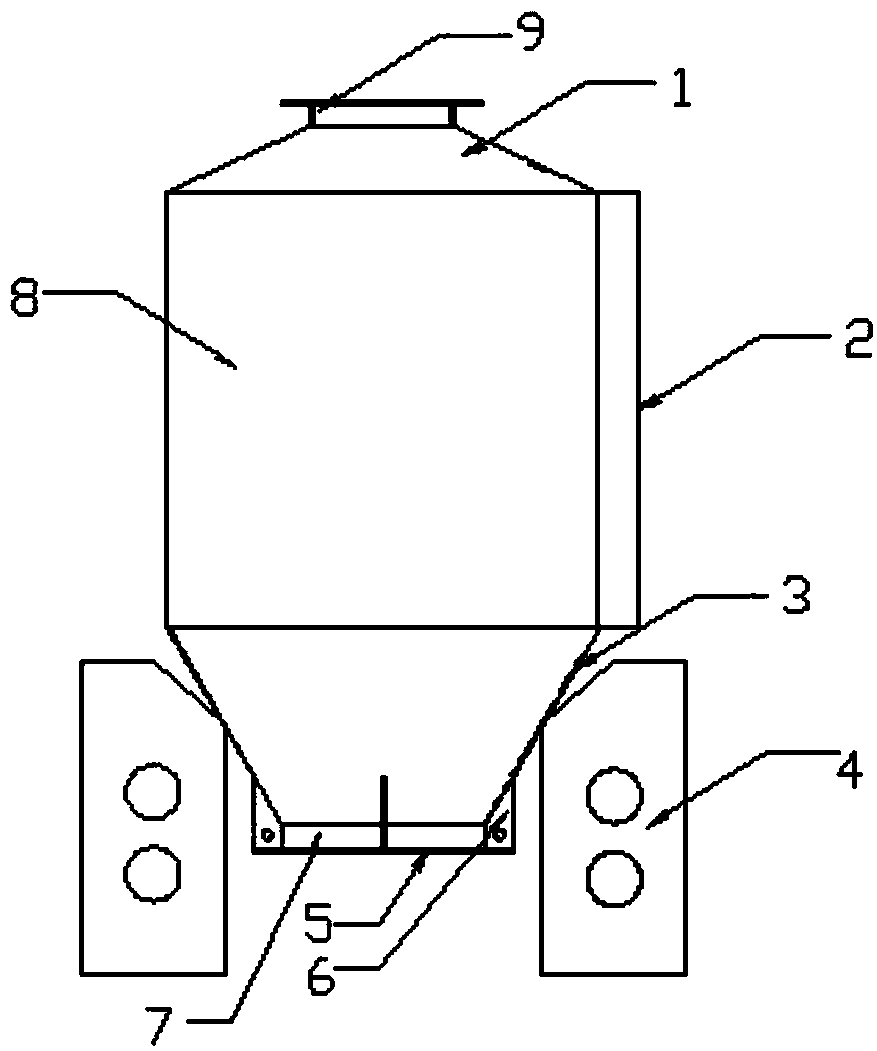

[0018] Example: such as figure 1 As shown, a small-sized steel silo with a cone bottom without a ring beam in the present invention includes a silo top cap 1, a ladder 2, a cone bucket 3, a base 4, a flange 5, a rib plate 6, a link ring 7, a silo body 8, and a feeding port 9. The top of the bin body 8 is connected to one end of the bin top cap 1, the end of the bin top cap 1 away from the bin body 8 is provided with the feeding port 9, and one side of the bin body 8 The ladder 2 is provided for the convenience of the operator to feed materials. The bottom end of the bin body 8 is connected to one end of the cone bucket 3. The bottom of the cone bucket 3 has light weight, low requirements on the foundation, low cost and easy assembly. Simple, short construction period, simple demolition and convenient maintenance, the end of the cone bucket 3 away from the warehouse body 8 is provided with the flange 5, the flange 5 is connected with the link ring 7, the The outer side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com