Continuous pouring seamless construction method of expansive concrete reinforcing band replacing post-pouring band

A technology of expansive concrete and expansive reinforcement strips, which is applied in the fields of architecture, strength characteristics, and building structures, can solve problems such as inability to accurately reflect the actual strength of structures, insufficient humidity in concrete, and a large amount of evaporation of concrete moisture, to achieve Maintain the strength and various properties, prevent the cement from continuing to hydrate, and avoid the effect of increasing drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

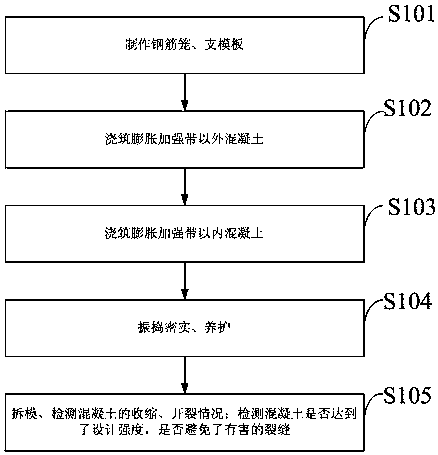

[0070] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0071] In the prior art, the method of reserving post-casting strips effectively avoids the harmful cracks that may occur in the cast-in-place reinforced concrete structure due to uneven shrinkage or uneven settlement, but a series of operations such as treatment of the concrete surface are required during the secondary pouring , otherwise it will affect the integrity of the components and cause uneven stress, so the method will lead to delays in the construction period.

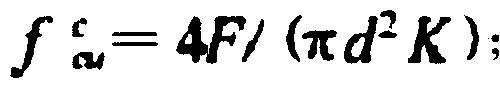

[0072] In the prior art, the strength test method of concrete cannot accurately reflect the actual strength of the structure, and is not suitable for the estimation of the strength of concrete in different periods. At the same time, the complexity of the equipment is increased, and the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com