Closestool flushing control system

A control system and toilet technology, applied in flushing toilets, flushing equipment with water tanks, buildings, etc., can solve the problems of poor flushing effect, poor flushing effect, single flushing mode, etc., and achieve good flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

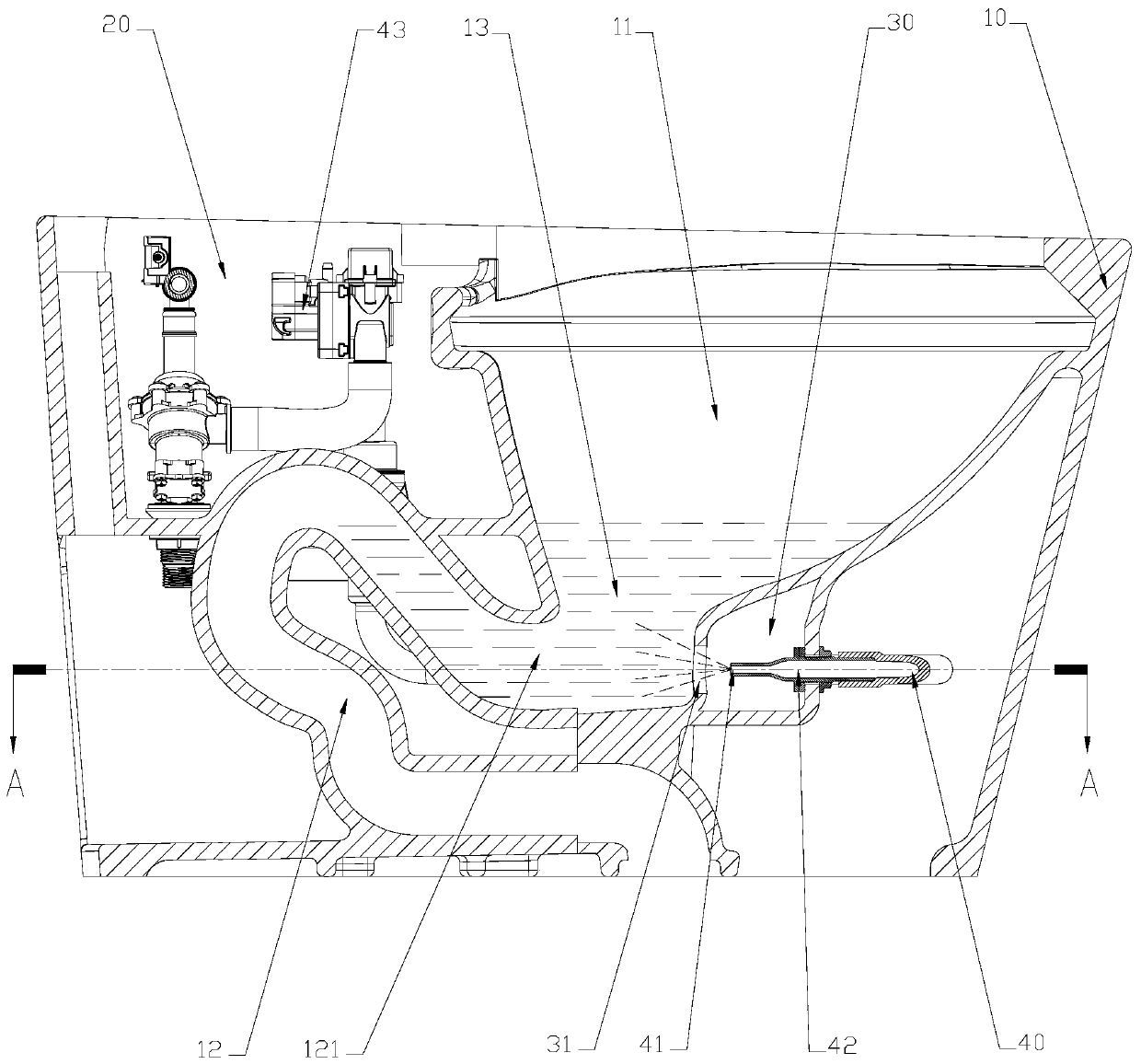

[0106] like Figure 5 As shown, in this embodiment, the control sequences of the first flushing water circuit 30, the second flushing water circuit 40, and the brush ring water circuit 50 are as follows: first, the brush ring control device 51 is turned on, and the brush ring After the control device 51 is turned on for a first preset time, it is turned off; and after the brush ring control device 51 is turned off, the first control device 32 and the second control device 43 are turned on. The device 32 and the second control device 43 are turned on at the same time, or, after the brush ring control device 51 is turned off, the first control device 32 is turned on before or after the second control device 43 (0S~2S); Further, the water inlet device 21 for supplying water to the water tank 20 is also included. After the second control device 43 is turned off, the water inlet device 21 is turned on.

[0107] In this embodiment, the first preset time is 0.5S˜8S.

[0108] In thi...

no. 2 example

[0114] like Image 6 As shown, in this embodiment, the control sequences of the first flushing water circuit 30, the second flushing water circuit 40, and the brush ring water circuit 50 are as follows: first, the brush ring control device 51 is turned on, and the first preset After setting the time, the brush ring control device 51 is turned off; then, the first control device 32 , the second control device 43 and the water inlet device 21 are turned on.

[0115] In this embodiment, the first preset time is 0.5S˜8S.

[0116] It should be noted that, in this embodiment, when the first control device 32 and the second control device 43 are turned on at the same time, the water inlet device 21 is also turned on at the same time; when the first control device 32 is turned on When the time is earlier or later than the opening time of the second control device 43, preferably, earlier or later than the opening time of 0S~2S, the water inlet device 21, the first control device 32 an...

no. 3 example

[0120] like Figure 7 As shown, in this embodiment, the control sequence of the first flushing water circuit 30, the second flushing water circuit 40, and the brush ring water circuit 50 adopts: first, the brush ring control device 51 and the water inlet device are turned on at the same time. 21. The brush ring control device 51 is turned on for a second preset time and then turned off, and after the brush ring control device 51 is turned off, the first control device 32 and the second control device 43 are turned on.

[0121] In this embodiment, the second preset time is 0.5S˜8S.

[0122] The remaining undescribed parts of this embodiment are similar to those of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com