Expansion shell bearing plate and anchor rod adopting same

A pressure-bearing plate and shell expansion technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problem of enhancing the bond strength between the anchor bolt grouting body and the rock-soil interface, and increasing the grouting body and the rock-soil body interface. Interface normal stress and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

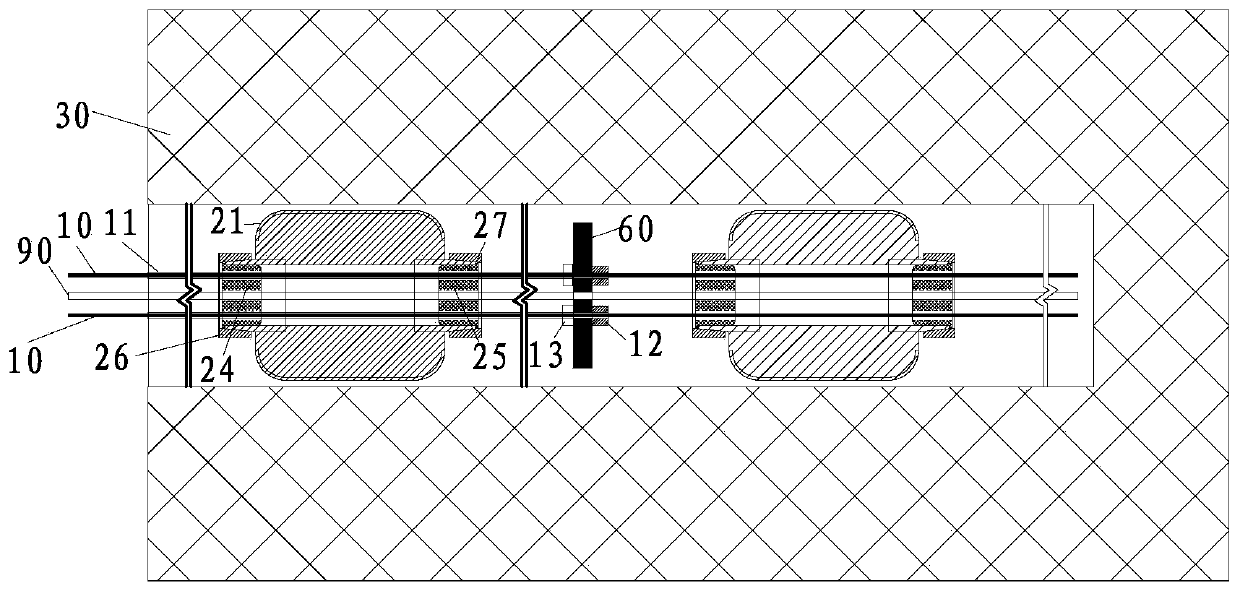

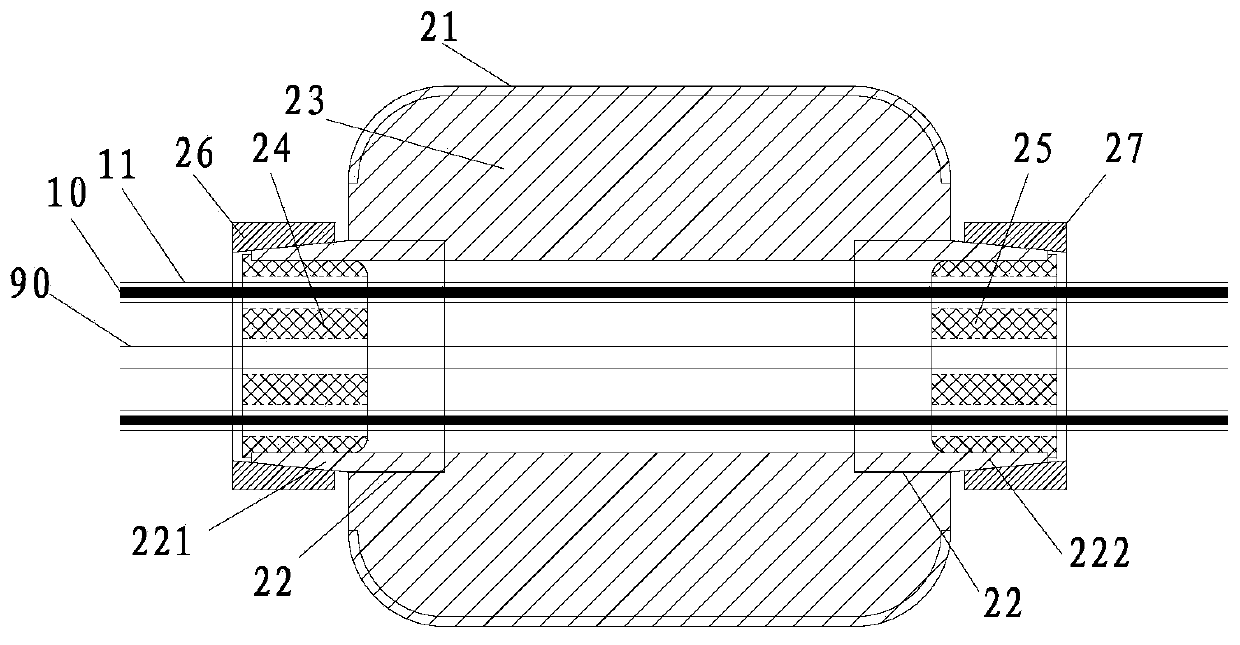

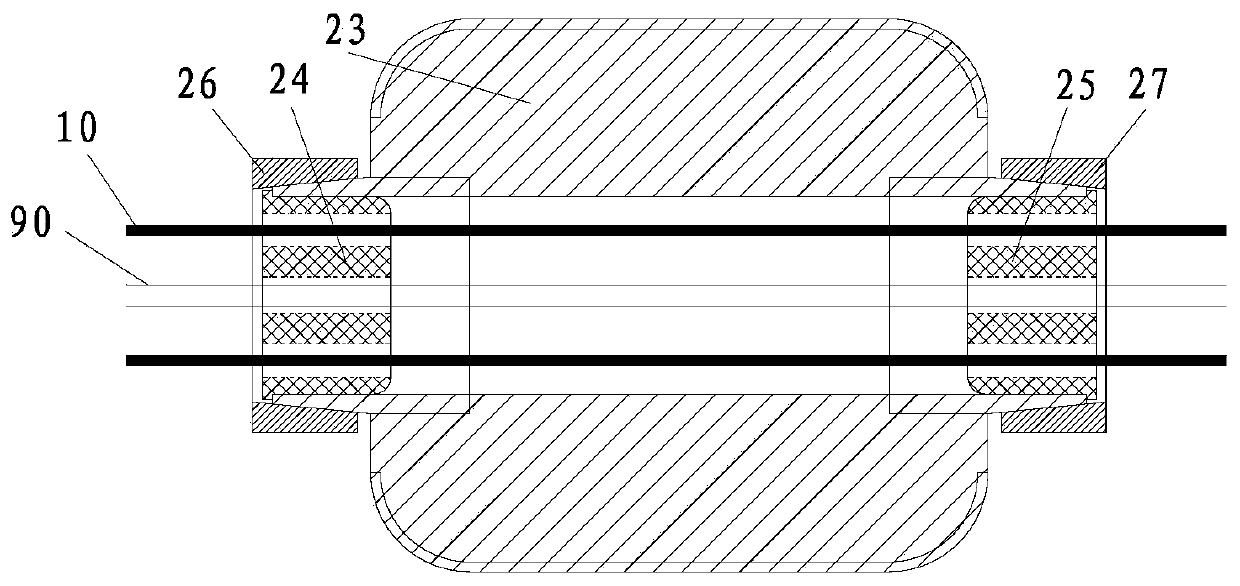

[0020] refer to Figure 1 to Figure 12, the present invention proposes a universal centering bracket, including a boat-shaped bracket, a first universal plug 24 , a second universal plug 25 , a first locking ring 26 and a second locking ring 27 . The boat-shaped support includes an outer cylinder 21, an inner cylinder 22 coaxially arranged at both ends of the outer cylinder 21, and a rib 23 connected between the outer cylinder 21 and the inner cylinder 22. The two ends of the inner cylinder 22 along the axial direction are provided with a first locking tongue cone. From the free end of the cylinder part 211 and the second cone cylinder part 212 toward the center of the inner cylinder 22, the outer diameters of the first cone cylinder part 211 and the second cone cylinder part 212 gradually increase. Large, the first universal plug 24 is embedded in the first deadbolt cone part 211, the second universal plug 25 is embedded in the second deadbolt cone part 212, the outer wall of...

Embodiment 2

[0027] refer to Figure 13 to Figure 23 , the assembled centering bracket, including a boat-shaped bracket and an assembly plug 40, the boat-shaped bracket includes an outer cylinder 21, an inner cylinder 22 coaxially arranged in the outer cylinder 21, and a rib 23 connected between the outer cylinder 21 and the inner cylinder 22, the inner The inner wall of the cylinder 22 is provided with an internal thread portion 225, and the outer wall of the assembly plug 40 is provided with an external thread portion 43 that cooperates with the internal thread portion 225. The assembly plug 40 is screwed into the inner cylinder 22, and the assembly plug 40 is provided with The reinforcement hole 41 for the anchor rod body 10 to pass through and the grouting pipe perforation 42 for pouring grout are respectively provided at both axial ends of the assembly plug 40 for restricting the movement of the assembly plug 40 on the anchor rod body 10 The first limiting member 51 and the second lim...

Embodiment 3

[0036] refer to Figures 24 to 27 , the present invention also proposes an expanding shell pressure bearing plate, which includes a conical pressure bearing plate, and the center of the conical pressure bearing plate is provided with a through hole 611 along the axial direction for the bolt body 10 to pass through, and the conical pressure bearing plate The plate has a flat plate portion 61 and a tapered portion 62 formed on the flat plate portion 61. The flat plate portion 61 and the tapered portion 62 are integrally formed. The two ends of the tapered portion 62 along the axial direction are respectively set as a connecting end and a free end. The diameter is larger than the outer diameter of the free end, and the connection between the connecting end and the flat plate portion 61 forms an annular extrusion platform 63, and the annular extrusion platform 63 is provided with a first annular pressure relief pad 64. As a preferred mode of the present invention, a second annular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com