Single-component silane-modified polyether sealant and production method and application thereof

A silane-modified polyether and sealant technology, which is applied in the field of construction sealants, can solve the problems of base material pollution and poor weather resistance, and achieve the effects of good adhesion, excellent weather resistance and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

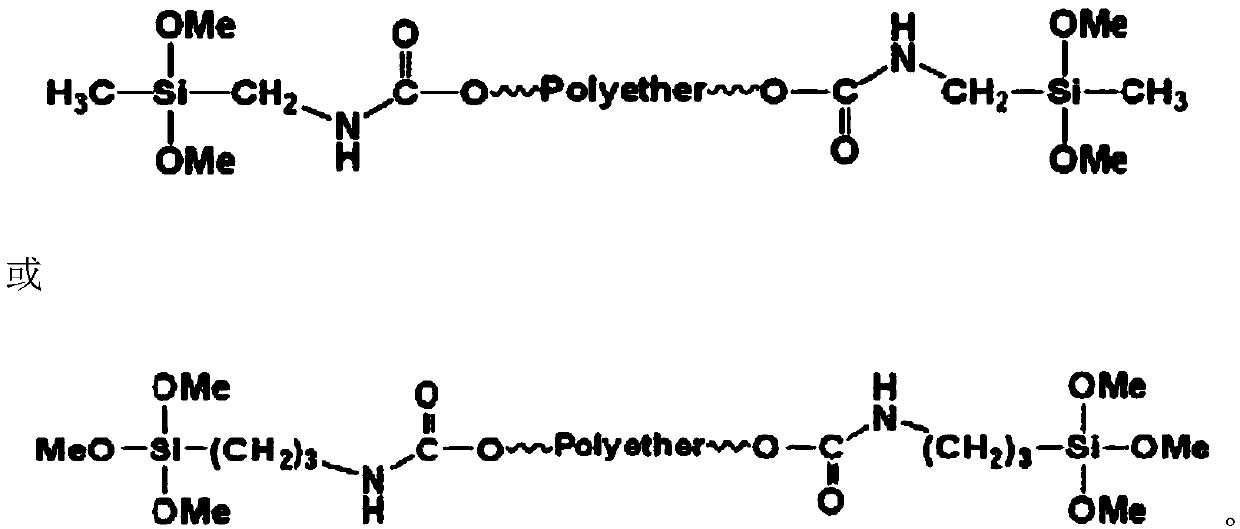

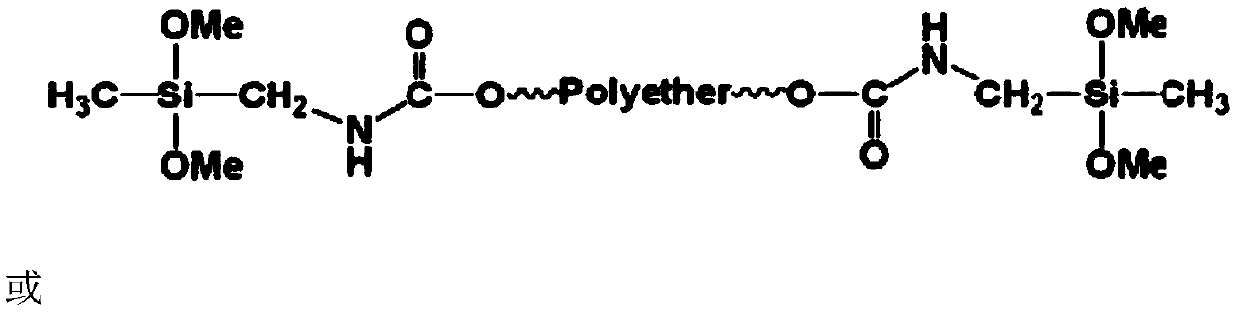

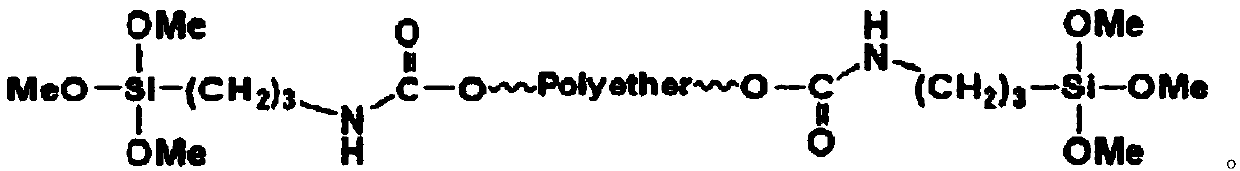

Image

Examples

Embodiment 1

[0038] A preparation method of a one-component silane-modified polyether sealant, comprising the following steps:

[0039] Step 1: Mix 30 parts of STP-E30, 10 parts of cyclohexane 1,2-diisononyl dicarboxylate, 20 parts of heavy calcium carbonate, 30 parts of nano calcium carbonate, 4 parts of titanium dioxide, 0.25 parts of UV326, 0.25 Add UV770 and 0.25 Irganox1010 into the stirring tank, stir in vacuum for 5 minutes, heat up to 100-110°C and stir in vacuum for 2 hours to dehydrate;

[0040] Step 2: Cool down to 80-85°C, add 2 parts of polyamide wax, vacuumize and stir for 30 minutes, and the stirring speed is 800rpm;

[0041] Step 3: Cool down to below 50°C under vacuum protection, add 1 part of vinyltrimethoxysilane, 0.6 part of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane, 0.4 part of γ-shrink Glyceryl ether oxypropyltrimethoxysilane, 0.3 parts of modified organotin compounds, and vacuum stirring for 30 minutes to obtain a one-component silane-modified polyether sealant...

Embodiment 2

[0043] A preparation method of a one-component silane-modified polyether sealant, comprising the following steps:

[0044] Step 1: Mix 10 parts of STP-E10, 15 parts of STP-E35, 15 parts of diisononyl phthalate, 23 parts of heavy calcium carbonate, 30 parts of nano calcium carbonate, 2 parts of carbon black, 0.20 parts of UV327, 0.3 Add 1 part of Tinuvin 123 and 0.20 part of Irganox 245 into the stirred tank, stir in vacuum for 5 minutes, heat up to 100-110°C and stir in vacuum for 2 hours to dehydrate;

[0045] Step 2: Cool down to 80-85°C, add 2 parts of polyamide wax, vacuumize and stir for 30 minutes, and the stirring speed is 800rpm;

[0046] Step 3: Reduce the temperature to below 50°C under vacuum protection, add 1 part of vinyltrimethoxysilane, 0.6 parts of γ-aminopropyltrimethoxysilane, 0.4 parts of γ-glycidyl etheroxypropyltrimethoxysilane, 0.3 parts of modified organotin compounds were stirred in vacuum for 30 minutes to obtain a one-component silane-modified polyethe...

Embodiment 3

[0048] A preparation method of a one-component silane-modified polyether sealant, comprising the following steps:

[0049] Step 1: Add 30 parts of STP-E30, 20 parts of STP-E15, 35 parts of nano calcium carbonate, 10 parts of heavy calcium carbonate, 3 parts of carbon black, 0.3 parts of UV326, 0.2 parts of Tinuvin123, 0.3 parts of Irganox1076 into the stirring tank , stir in vacuum for 5 minutes, heat up to 100-110°C and stir in vacuum for 2 hours to dehydrate;

[0050] Step 2: Cool down to 80-85°C, add 1 part of polyamide wax, vacuumize and stir for 30 minutes, and the stirring speed is 700rpm;

[0051] Step 3: Cool down to below 50°C under vacuum protection, add 1 part of vinyltrimethoxysilane, 0.7 part of γ-aminopropyltrimethoxysilane, 0.3 part of γ-glycidyl etheroxypropyltrimethoxysilane, 0.4 parts of modified organotin compounds were stirred in vacuum for 30 minutes to obtain a one-component silane-modified polyether sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com