3C industry orientated modular multi-cantilever multifunctional device

A multi-functional equipment and modular technology, applied in the direction of conveyor objects, electrical components, transportation and packaging, etc., can solve the problems of increasing the time for line change processing, difficulty in meeting market demand, and large floor space, etc., to achieve structural Compactness, reduced input costs, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

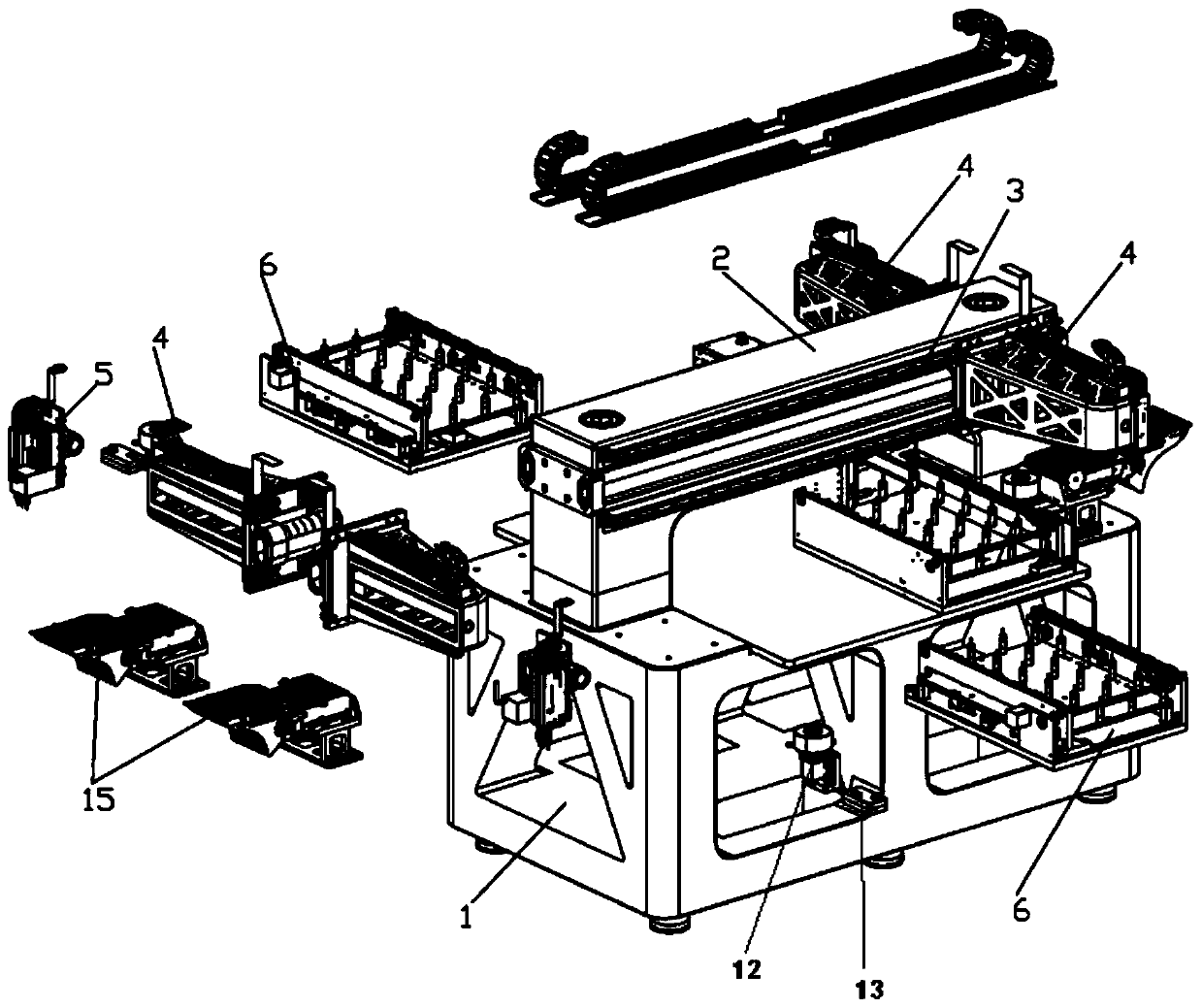

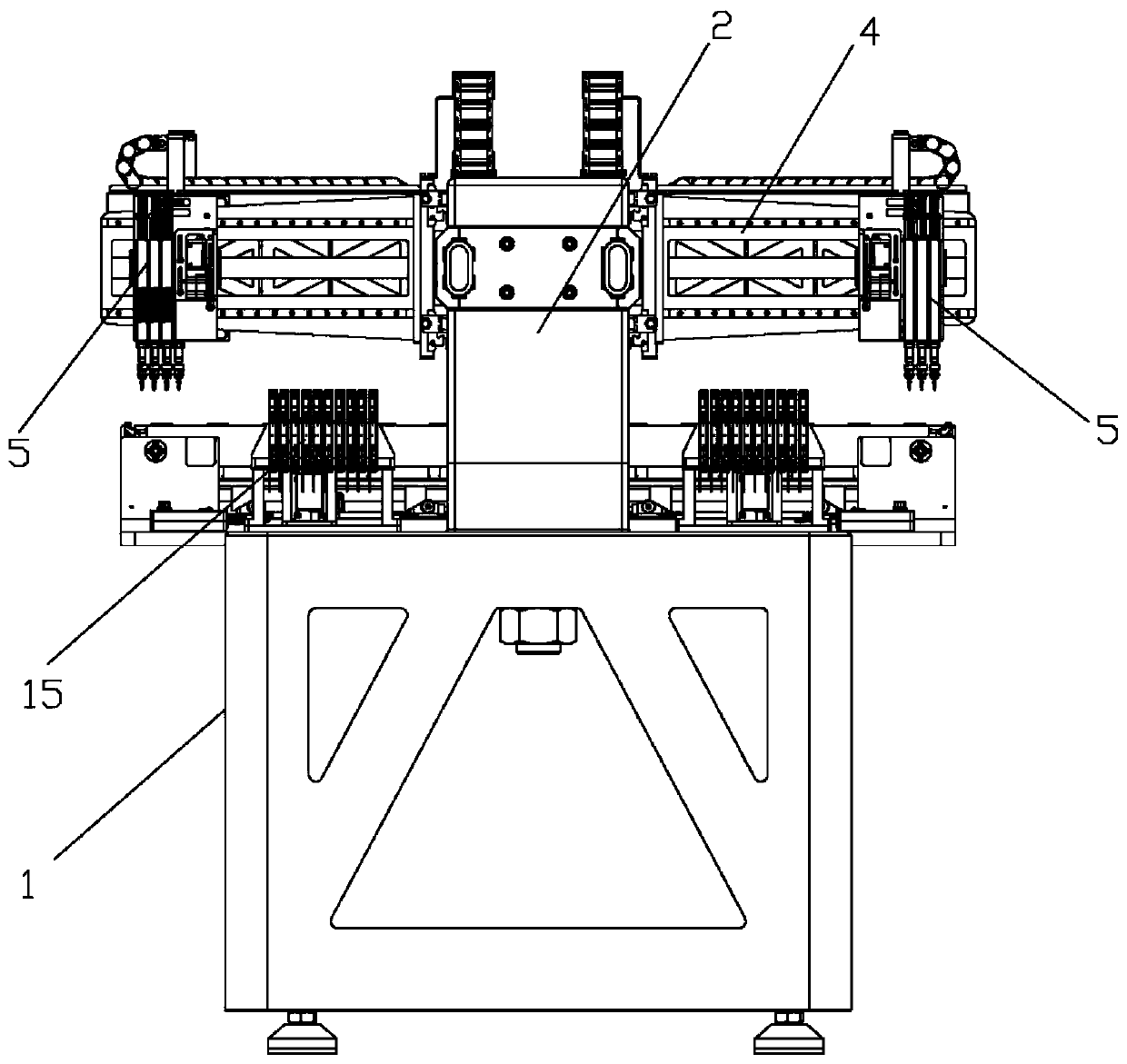

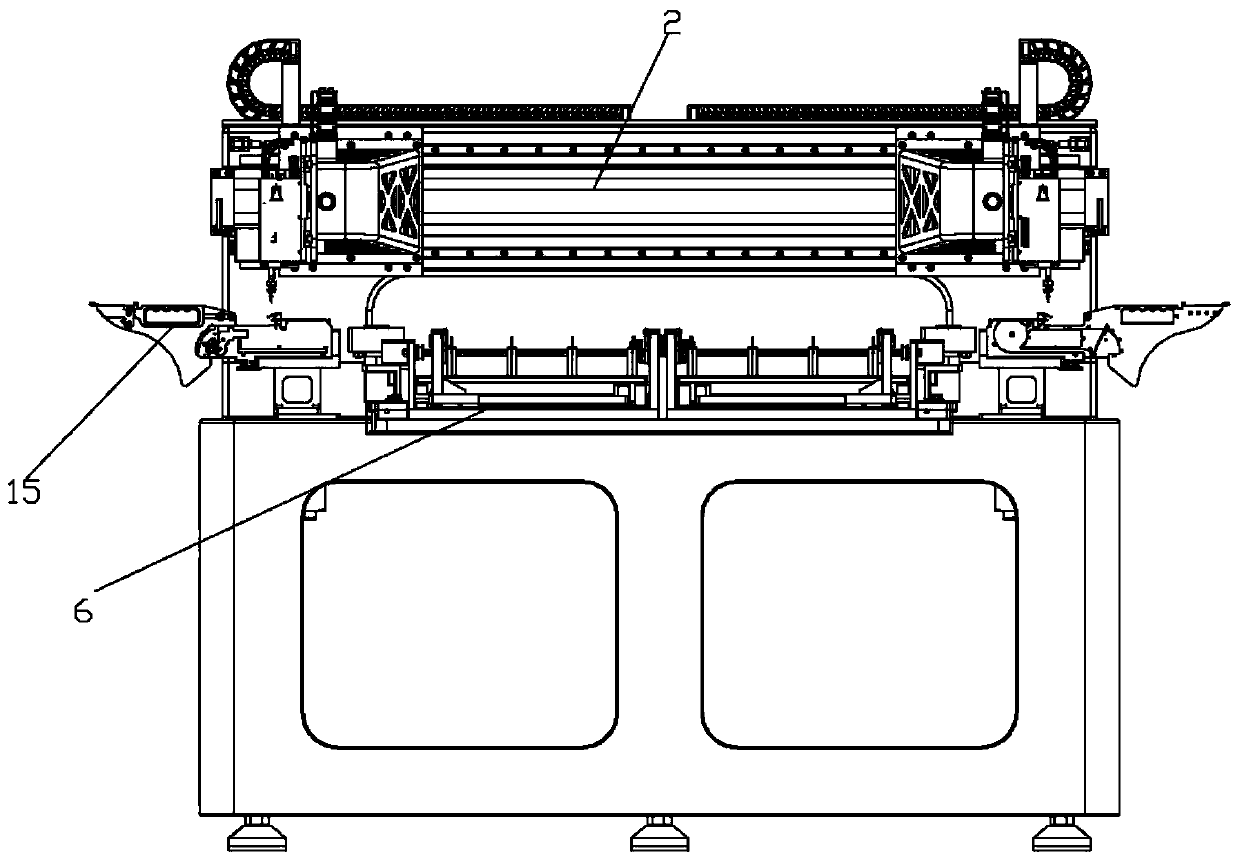

[0055] Embodiment one: if Figure 1 to Figure 20 As shown in the figure, a modular multi-cantilever multifunctional equipment for the 3C industry includes a main body module 1, a detachable beam module 2 is fixedly installed on the main body module 1, and X-axis linear motors are arranged symmetrically on both sides of the beam module 2 Drive module 3, two X-axis linear motor drive modules 3 are equipped with two Y-axis cantilever modules 4, and two Y-axis cantilever modules 4 are equipped with at least one Z-axis sub-module 5 that can be replaced with different execution functions , the upper end of the main module 1 is located below the beam module 2, and four jig feeding modules 6 are provided, and every two jig feeding modules 6 form a jig feeding channel, and the upper end of the main module 1 is also provided with four feeding sub-modules 15, The four feeding sub-modules 15 are set corresponding to the four Y-axis cantilever modules 4 . The two jig feeding channels are ...

Embodiment 2

[0066] Embodiment 2: A modular multi-cantilever multifunctional device for the 3C industry, including a main body module 1, a detachable beam module 2 is fixedly installed on the main body module 1, and X-axis straight lines are arranged symmetrically on both sides of the beam module 2 Motor drive module 3, two X-axis linear motor drive modules 3 are provided with two Y-axis cantilever modules 4, two Y-axis cantilever modules 4 are provided with at least one Z-axis sub-module 5, the upper end of the main module 1 is located Four jig feeding modules 6 are arranged below the beam module 2, and every two jig feeding modules 6 form a jig feeding channel. The upper end of the main module 1 is also provided with four feeding sub-modules 15, four feeding sub-modules 15 Corresponding to the four Y-axis cantilever modules 4 are set. The four feeding sub-modules 15 are located between the two jig feeding channels; the four Y-axis cantilever modules 4 all take components from the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com