Vibrating discharging device on color sorting machine

A vibrating discharge device and color sorter technology, applied in the field of color sorters, can solve the problems of materials falling out of the receiving hopper, easily entrained materials, crushed materials entering the receiving hopper, etc., achieving simple structure, low cost, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

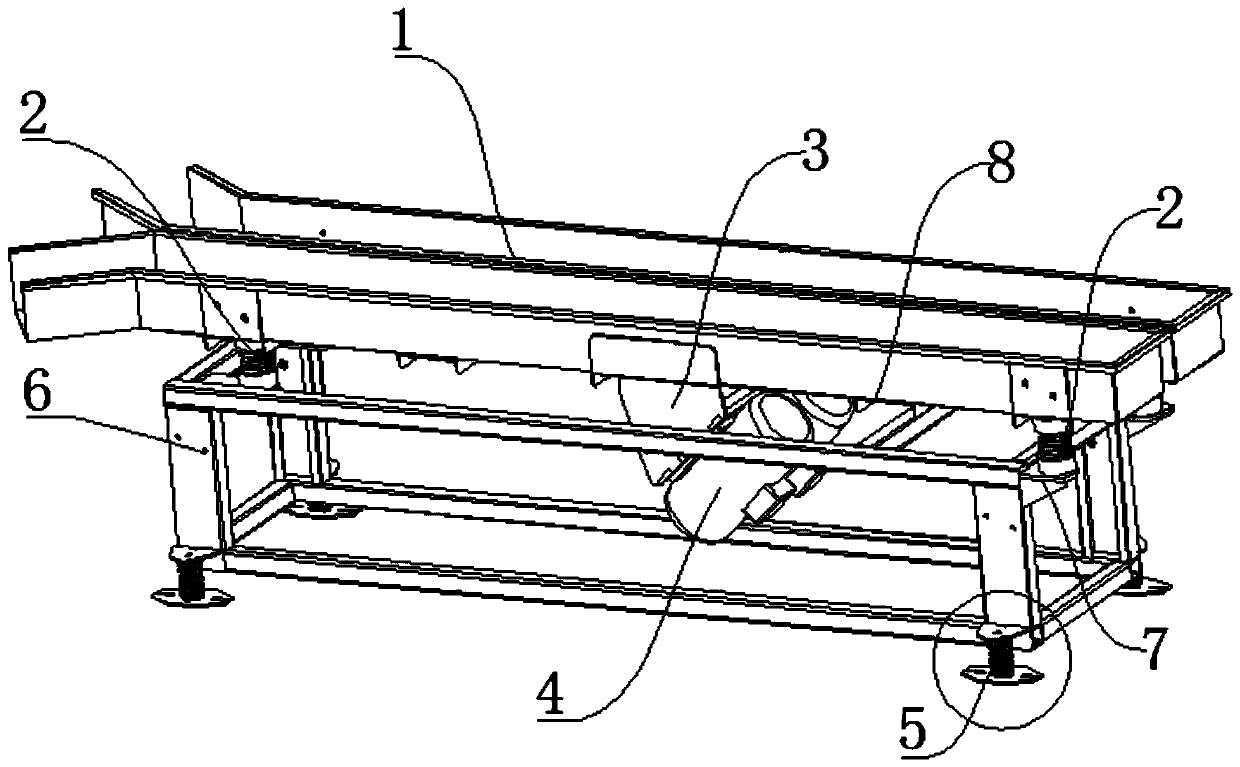

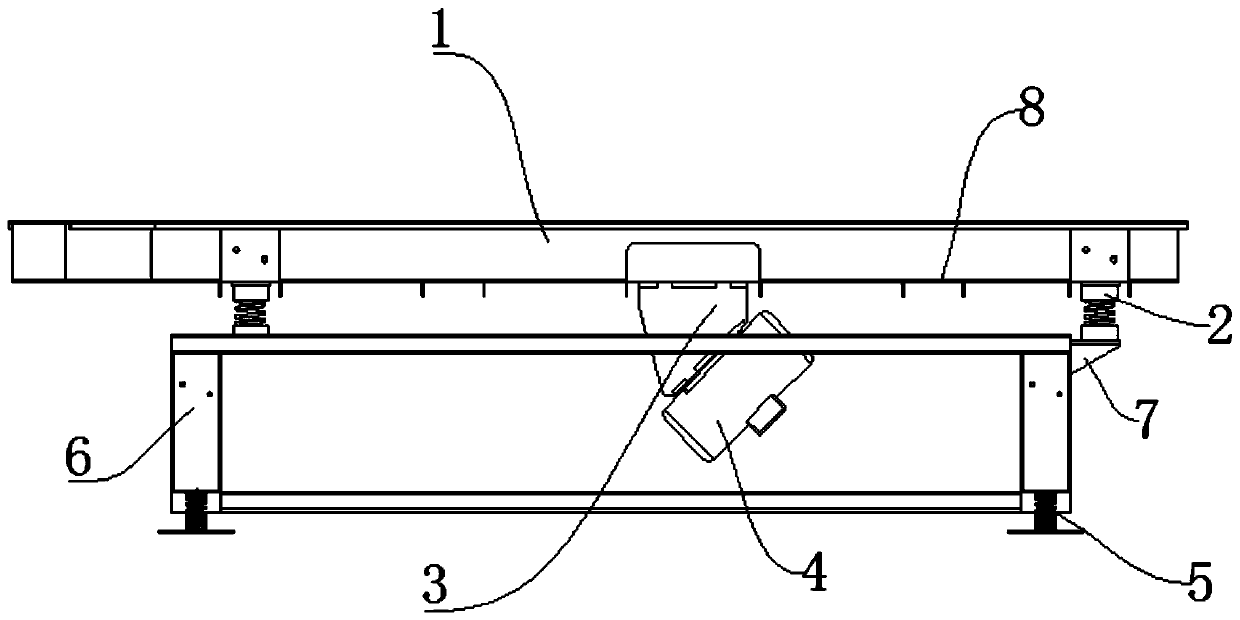

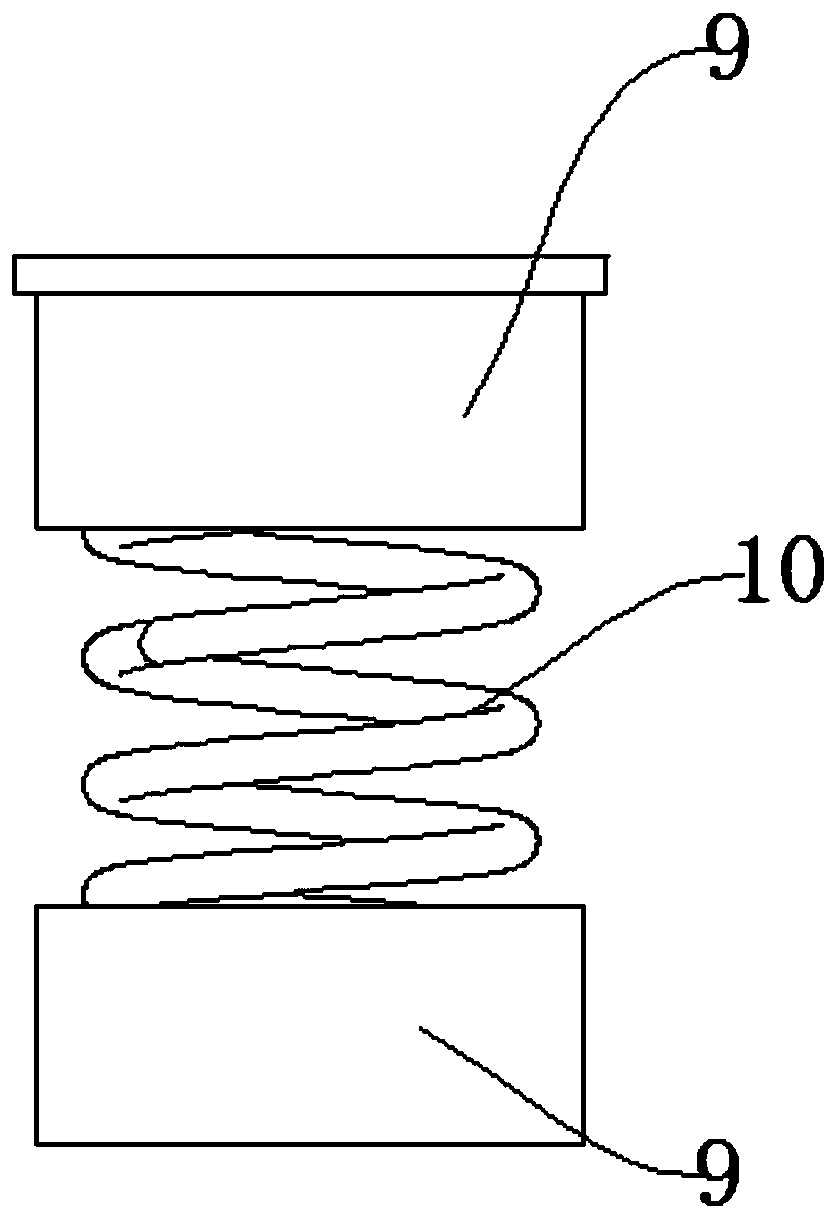

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this specific embodiment adopts the following technical solutions: it includes a double discharge hopper 1, a spring support assembly 2, a motor seat 3, a vibration motor 4, a shock absorbing base 5, a hopper support frame 6, a fixing seat 7, and a strengthening connection frame 8. Spring limit ring 9, first shock absorbing support spring 10, upper fixing plate 11, second shock absorbing support spring 12, bottom anti-skid plate 13, anchor bolt fixing groove 14, the four corners below the hopper support frame 6 are provided with The shock-absorbing base 5, the four corners above the hopper support frame 6 are provided with a fixed seat 7, the fixed seat 7 is provided with a spring support assembly 2, the spring support assembly 2 is provided with a double discharge hopper 1, and the double discharge hopper 1 is provided on the lower surface. Reinforce the connecting frame 8, a motor seat 3 is provided un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com