D-series high-speed train and sanding lubrication system

A technology for a lubrication system and an EMU, which is applied to the EMU and its sand-spraying lubrication system, can solve the problems of increasing the number of wheel grinding and maintenance costs, increasing the risk of wheel and track separation, and increasing wheel rim wear. Achieve the effect of reducing the number of times and maintenance costs, reducing the probability of sliding, and reducing wheel wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

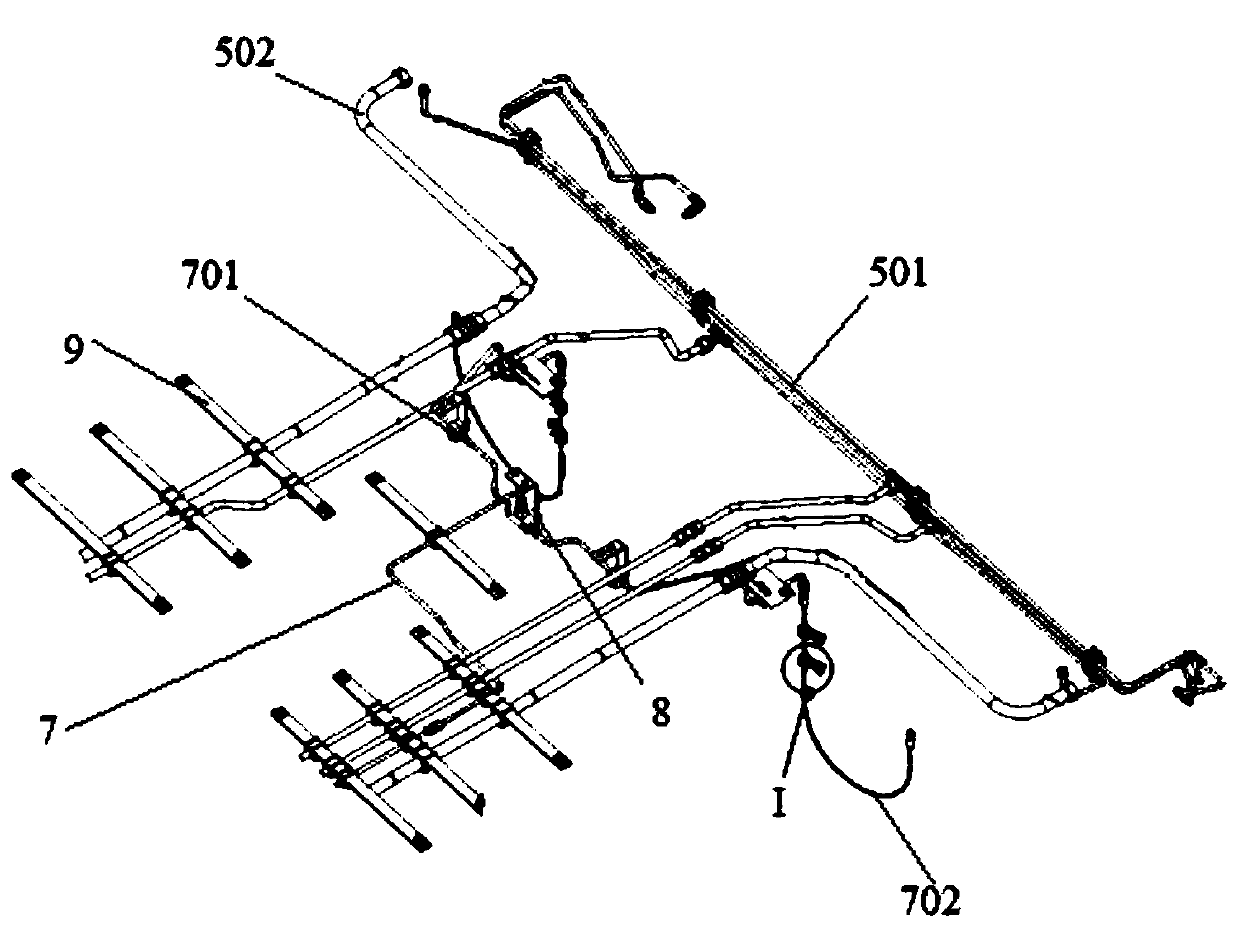

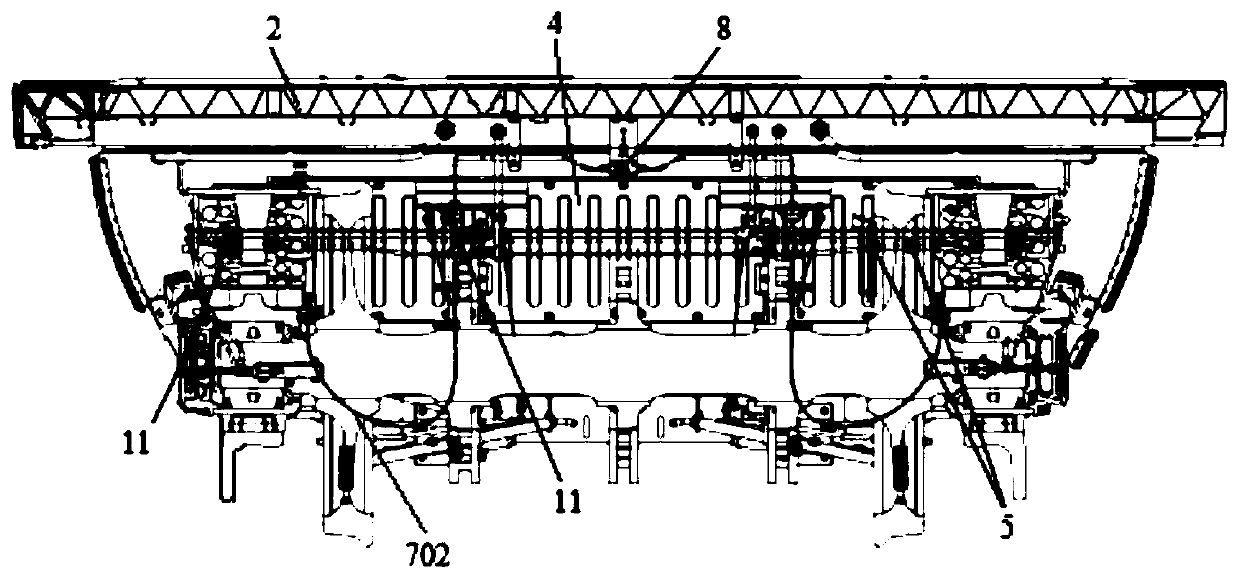

[0055] like Figure 1-6 As shown, the present invention discloses a sand-spraying lubrication system for EMUs. Since the braking and lubrication of EMUs are mainly performed on the head car of EMUs, the sand-spraying lubrication system disclosed in the present invention is often used in EMUs It should be noted that it can also be installed on other car bodies that require lubrication and braking.

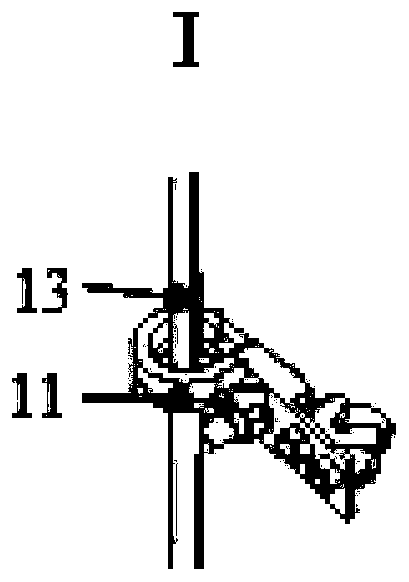

[0056] The sanding lubrication system includes a sand box 1, a sanding pipe 5, a sandblasting nozzle, a lubricant supply device, a lubricating pipe 7 and an oil injection nozzle.

[0057] Wherein, the EMU comprises an underframe 2 and a bogie 3, the bogie 3 is rotatably mounted on the underframe 2, and a deflector 4 is arranged between the dynamic front end of the bogie 3 and the underframe 2, so as to improve the performance of the EMU. Dynamic performance, reducing the running resistance of the EMU. The sand box 1 is arranged between the bogie 3 and the dynamic front end of the ...

Embodiment 2

[0065] In the second embodiment provided by the present invention, the structure of the sanding and lubricating system in this embodiment is similar to that in the first embodiment, so the similarities will not be repeated, and only the differences will be introduced.

[0066] In this embodiment, the present invention specifically discloses that the lubricant supply device includes a drive pump, an oil-air mixing block and a distributor 8 .

[0067] A driven pump drives the lubricant into the oil-air mixing block. The distributor 8 is installed on the lubricating pipe 7, and through the lubricating pipe 7, it is connected with the outlet of the oil-air mixing block, and the two outlets of the distributor 8 are respectively connected with the oil nozzles on both sides through the lubricating pipe 7, so as to provide The wheels 6 on both sides of the group are sprayed with lubricant.

[0068] Specifically, the driving pump may be an air-operated plunger pump, and it should be n...

Embodiment 3

[0085] The present invention provides an EMU, comprising an undercarriage 2, a bogie 3 and the sand-sprinkling lubrication system in any one of the above-mentioned embodiments.

[0086] The bogie 3 is rotatably mounted on the underframe 2, and a deflector 4 is arranged between the dynamic front end of the bogie 3 and the underframe 2. The deflector 4 is provided with a plurality of flow guide grooves to improve the safety of the EMU. Dynamic performance, reducing the running resistance of the EMU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com