Biomimetic skeleton type memory alloy collision buffer

A technology of memory alloy and buffer, which is applied to bumpers and other directions, can solve the problems of affecting the effect of buffer energy absorption, large weight reduction space, and redundant material thickness, so as to improve the effect of buffer energy absorption, reduce the overall weight, and improve the buffer The effect of energy absorption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

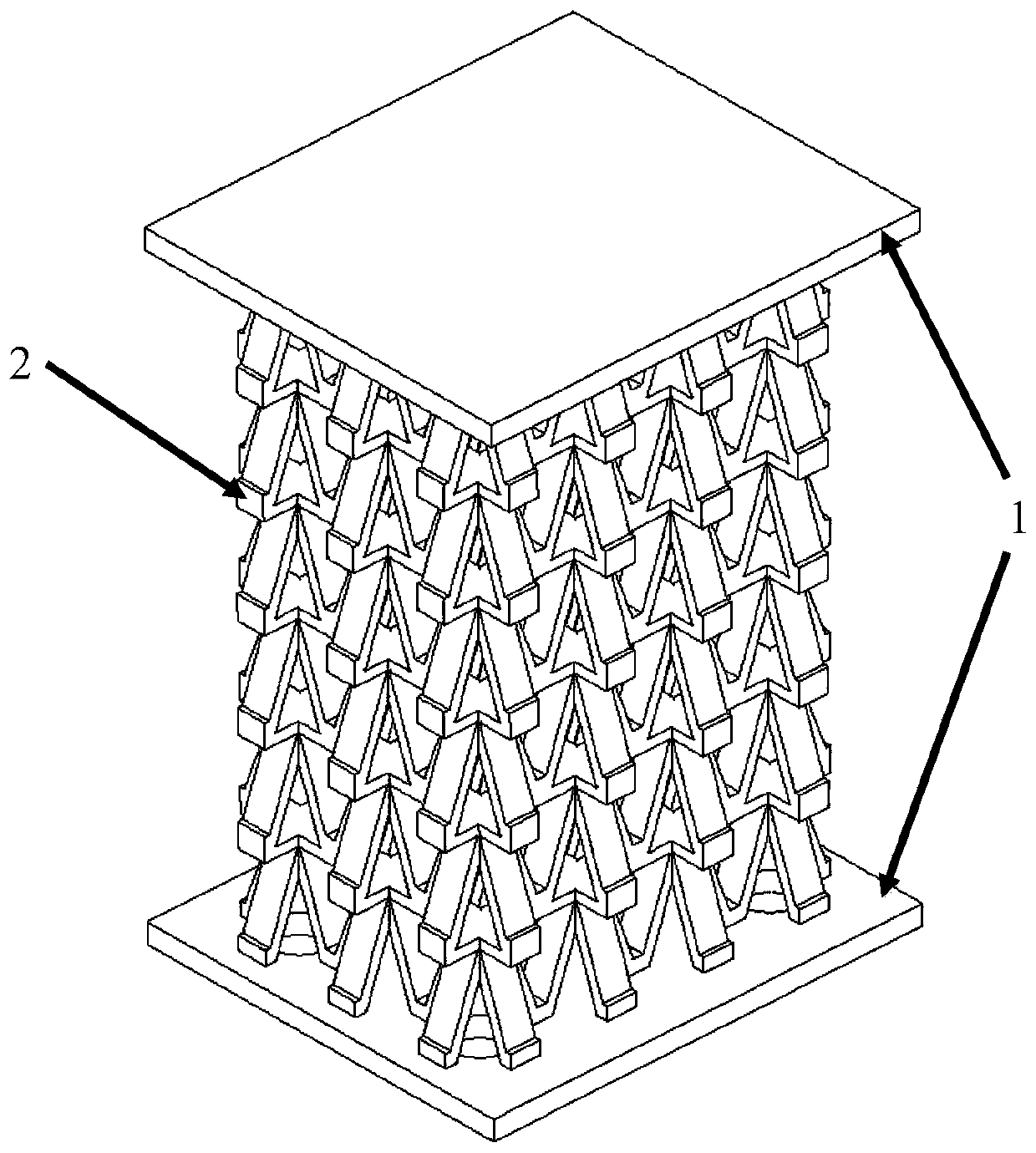

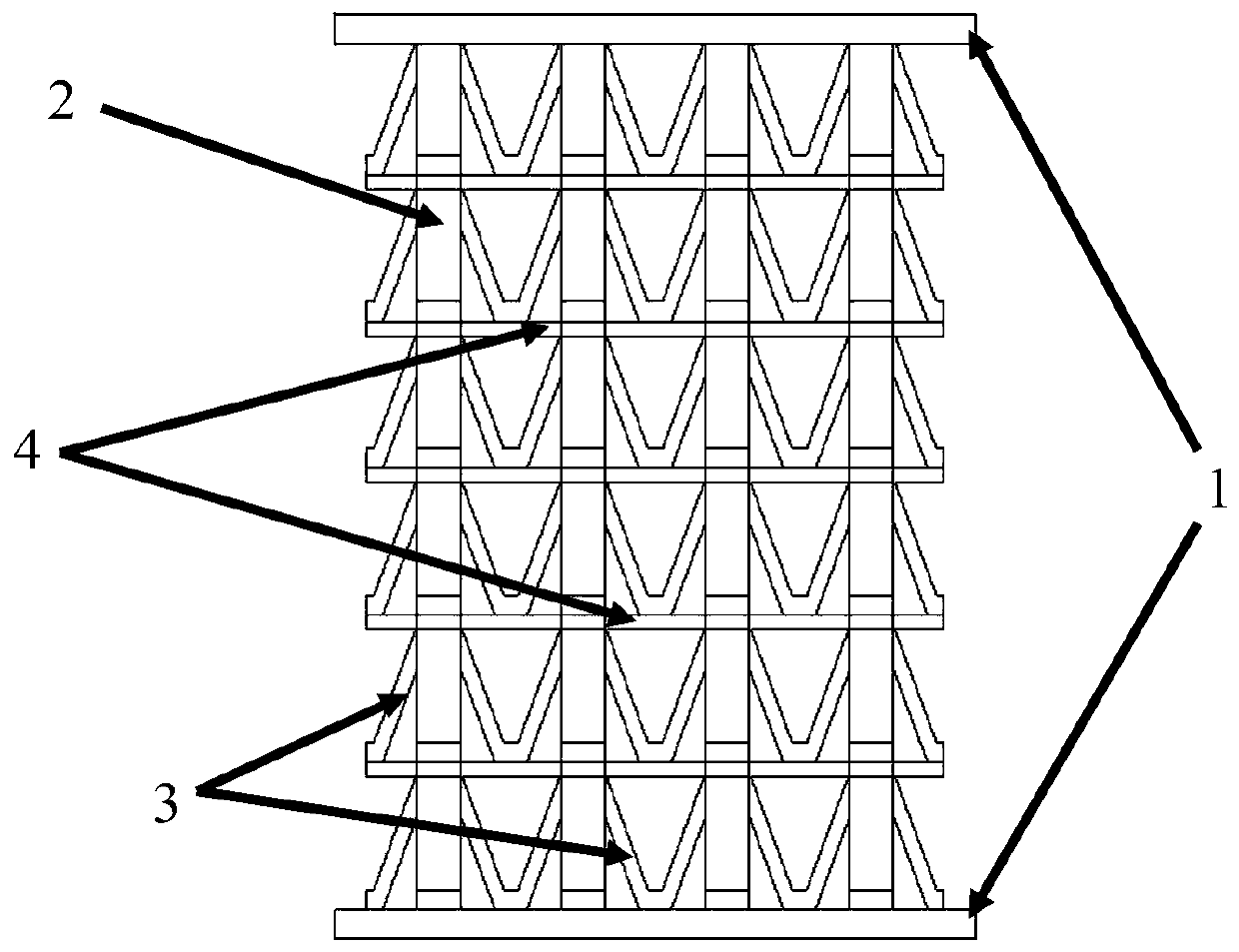

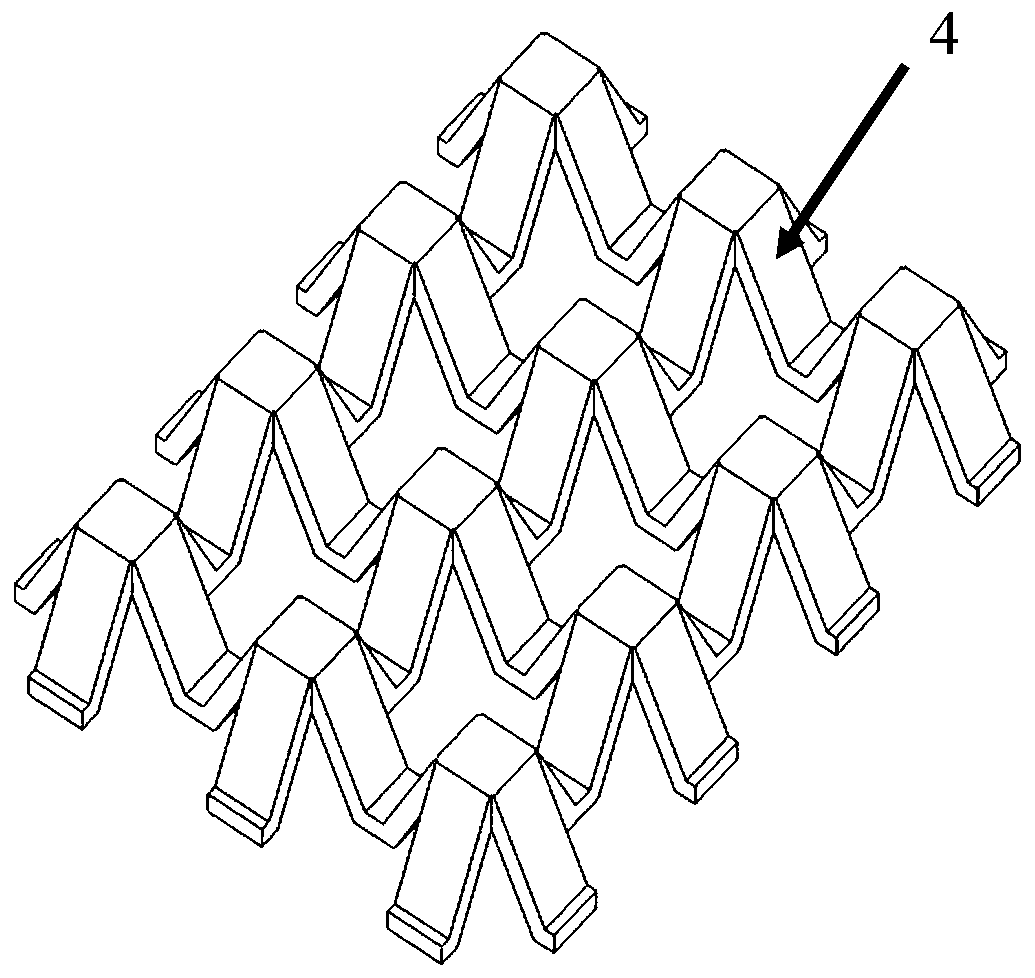

[0019] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a carbon fiber composite material covering layer 1 and a NiTi shape memory alloy bionic bone 2, the upper and lower surfaces of the NiTi shape memory alloy bionic bone 2 are covered with a carbon fiber composite material covering layer 1, and the carbon fiber composite material covering layer 1 passes through Oxidized resin glue is bonded and fixed together to form a collision buffer; the NiTi shape memory alloy bionic bone 2 is composed of an M-shaped NiTi alloy bracket 4 and a well-shaped NiTi alloy sheet 3, and the M-shaped NiTi alloy bracket 4 is welded on the well-shaped A single-layer skeleton structure is formed on the NiTi alloy thin plate 3 , and the single-layer skeleton structure is welded layer by layer to form a NiTi shape memory alloy bionic skeleton 2 .

[0020] The carbon fiber composite material covering layer 1 is used as the upper and lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com