Composite material for manufacturing elastic operating instrument sets, and preparation method thereof

A technology of composite materials and surgical packs, which is applied in the field of surgical pack materials, can solve the problems that the surgical pack materials are difficult to meet the functional requirements, and achieve the effects of reduced sterilization links, good toughness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

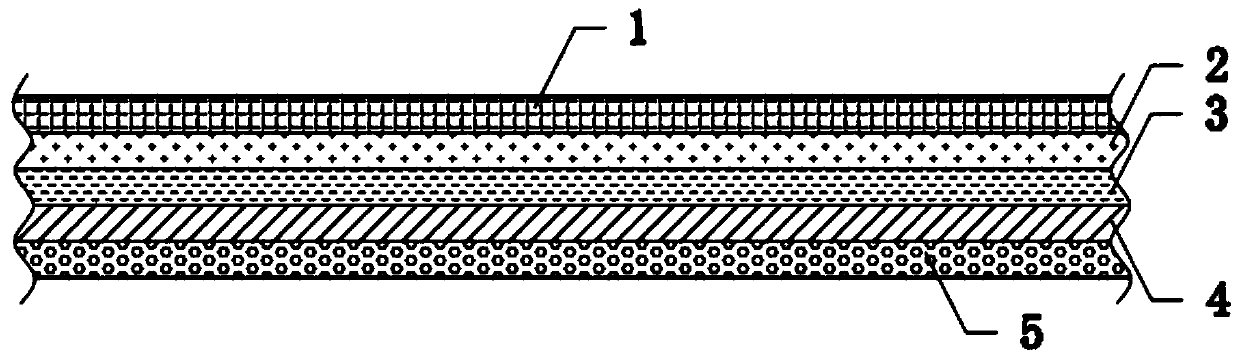

Image

Examples

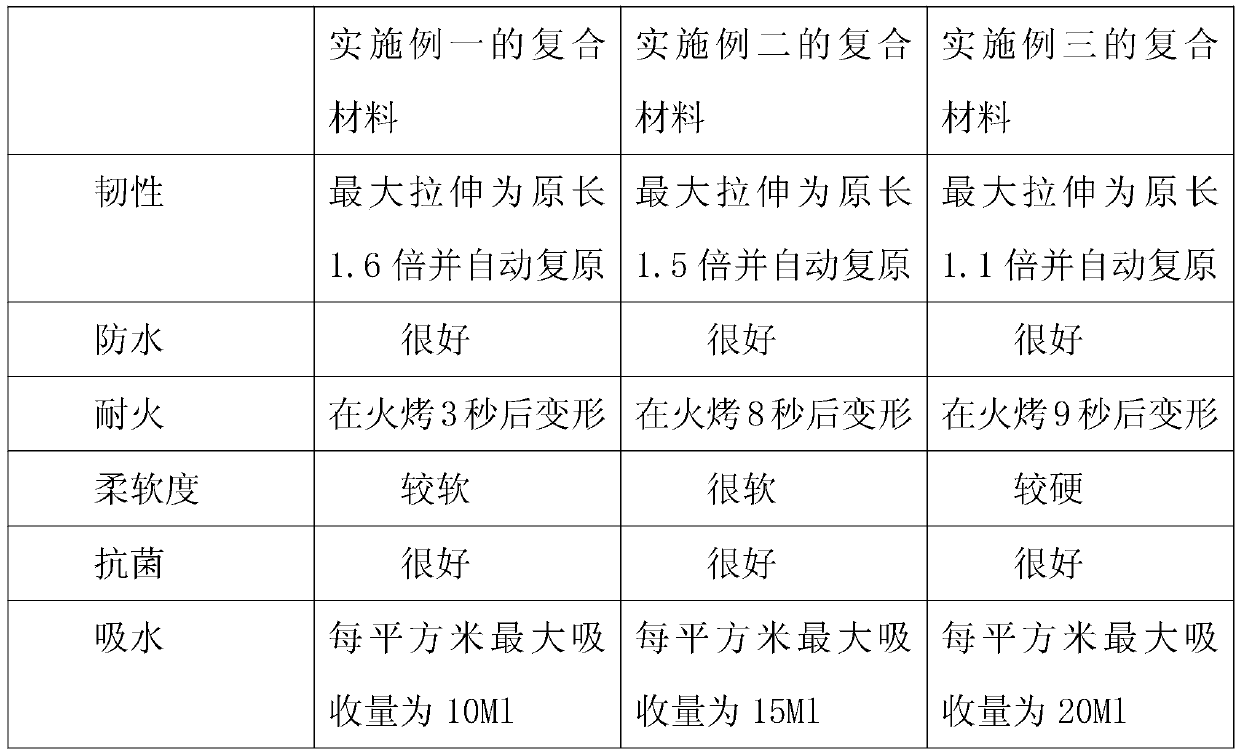

Embodiment 1

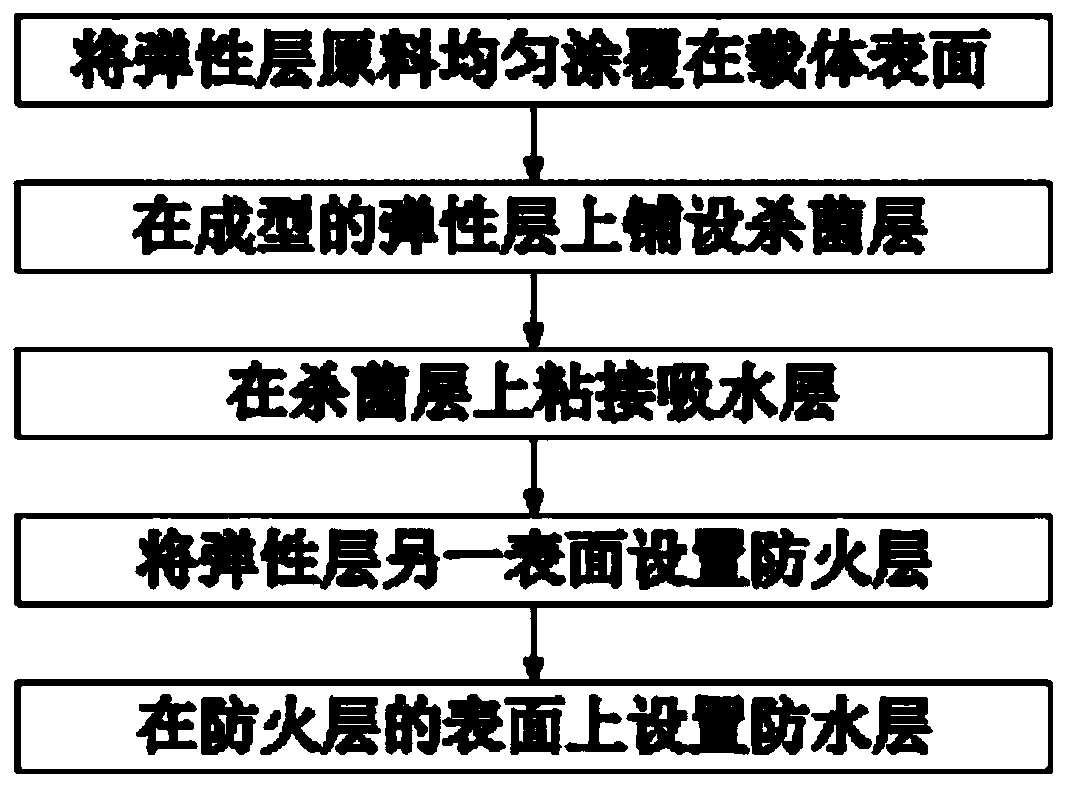

[0041] The specific steps of the preparation method for making the composite material of the elastic surgical bag are as follows:

[0042] S1: Coat the raw material of styrene-butadiene rubber evenly on the surface of the carrier: use smooth stainless steel as the carrier, apply anti-stick oil film coating on the surface of the stainless steel carrier in advance, and evenly coat the heated styrene-butadiene rubber raw material on the carrier On the surface of the styrene-butadiene rubber and cis-butadiene rubber mixed raw materials are cooled and formed to obtain the styrene-butadiene rubber base layer, and the thickness of the styrene-butadiene rubber base layer is 0.1mm;

[0043] S2: Pave nano-silver antibacterial coating on the formed styrene-butadiene rubber base: uniformly spray hot-melt adhesive on one side surface of the styrene-butadiene rubber base obtained in step S1, and spray nano-silver antibacterial coating on the hot-melt adhesive, The thickness of nano-silver a...

Embodiment 2

[0048] The specific steps of the preparation method for making the composite material of the elastic surgical bag are as follows:

[0049] S1: Coat the raw material of styrene-butadiene rubber evenly on the surface of the carrier: use smooth stainless steel as the carrier, apply anti-stick oil film coating on the surface of the stainless steel carrier in advance, and evenly coat the heated styrene-butadiene rubber raw material on the carrier On the surface of the styrene-butadiene rubber and cis-butadiene rubber mixed raw materials are cooled and formed to obtain the styrene-butadiene rubber base layer, and the thickness of the styrene-butadiene rubber base layer is 0.175mm;

[0050] S2: Pave nano-silver antibacterial coating on the formed styrene-butadiene rubber base: uniformly spray hot-melt adhesive on one side surface of the styrene-butadiene rubber base obtained in step S1, and spray nano-silver antibacterial coating on the hot-melt adhesive, The thickness of nano-silver a...

Embodiment 3

[0055] The specific steps of the preparation method for making the composite material of the elastic surgical bag are as follows:

[0056] S1: Coat the raw material of styrene-butadiene rubber evenly on the surface of the carrier: use smooth stainless steel as the carrier, apply anti-stick oil film coating on the surface of the stainless steel carrier in advance, and evenly coat the heated styrene-butadiene rubber raw material on the carrier On the surface of the styrene-butadiene rubber and cis-butadiene rubber mixed raw materials are cooled and formed to obtain the styrene-butadiene rubber base layer, and the thickness of the styrene-butadiene rubber base layer is 0.25mm;

[0057] S2: Pave nano-silver antibacterial coating on the formed styrene-butadiene rubber base: uniformly spray hot-melt adhesive on one side surface of the styrene-butadiene rubber base obtained in step S1, and spray nano-silver antibacterial coating on the hot-melt adhesive, The thickness of nano-silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com