Corrugated carton and preparation method thereof

A technology for corrugated boxes and corrugated paper, applied in the field of corrugated boxes and their preparation, can solve the problems of waste of carton materials, reduced compressive strength, and failure to find the carton in time, so as to reduce the loss of goods, improve the sensitivity of discoloration, and protect against oxidation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

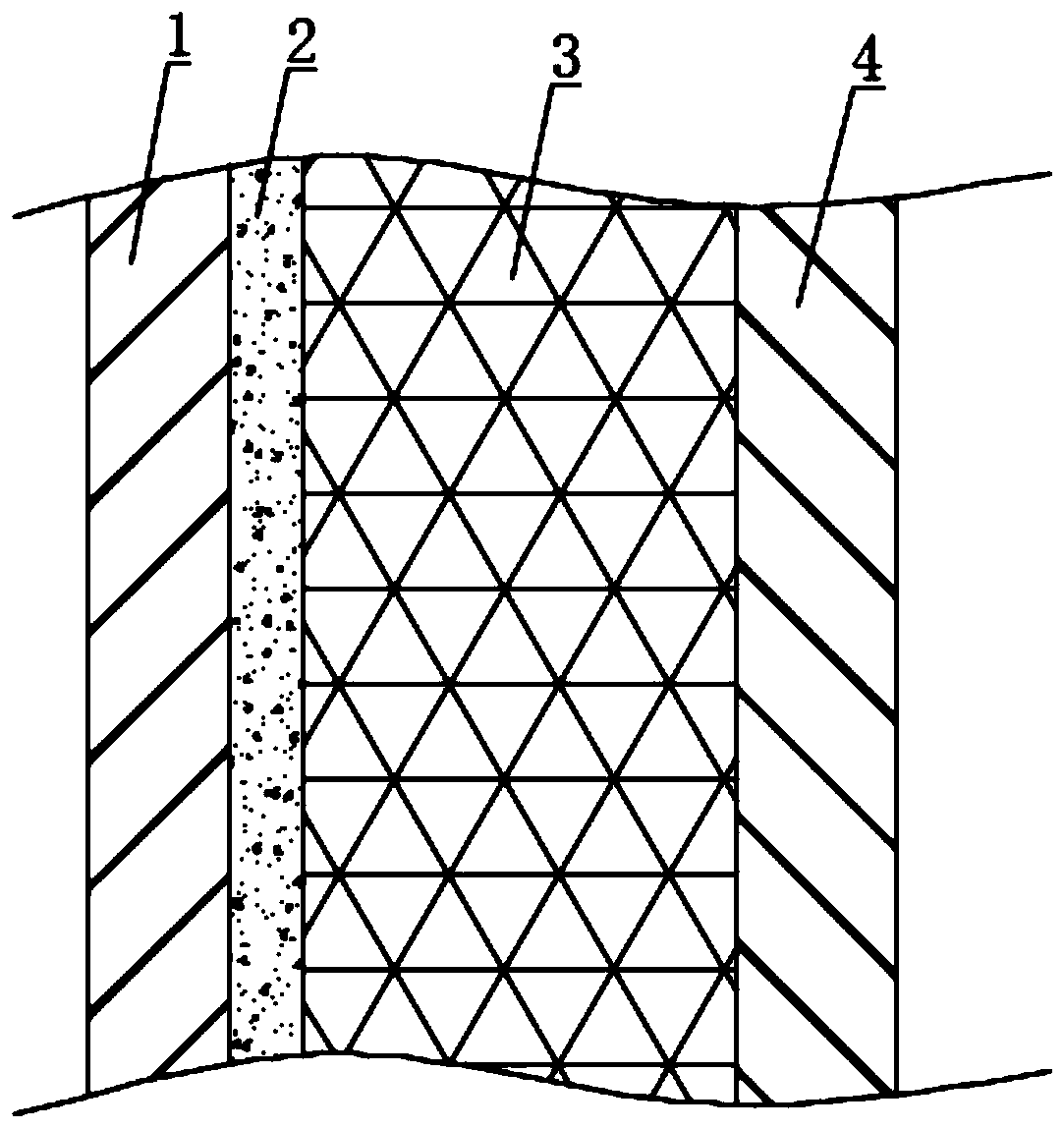

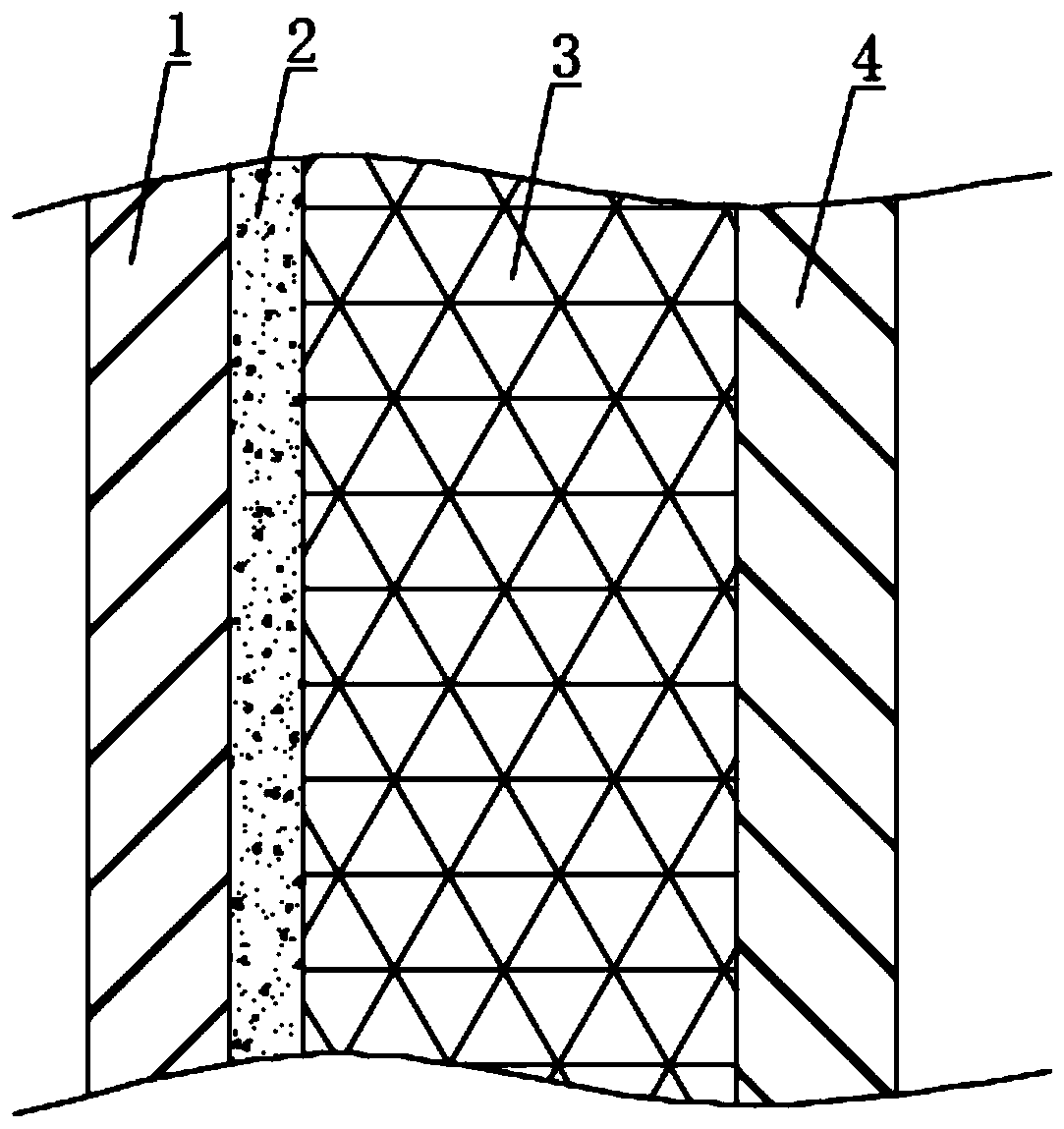

[0039] See figure 1 , A corrugated cardboard box, including a box body composed of corrugated cardboard, the corrugated cardboard includes outer transparent waterproof paper 1, corrugated paper 3 and inner transparent waterproof paper 4 arranged sequentially from the outside to the inside, through the outer transparent waterproof paper 1 and the inner transparent waterproof paper The paper 4 makes the box body have a certain waterproof function. Between the outer transparent waterproof paper 1 and the corrugated paper 3, there is a moisture-sensitive color-changing film 2 formed by spraying a moisture-sensitive color-changing compound reagent. The moisture-sensitive color-changing film 2 includes phenolic resin and anhydrous ethanol. , Calcium carbonate, color changing agent, color developing agent, hygroscopic agent, antioxidant and film forming aid, the color changing agent includes purple sweet potato and ethanol solution. The present invention uses spray film forming method t...

Embodiment 2

[0054] See figure 1 , A corrugated cardboard box, including a box body composed of corrugated cardboard, the corrugated cardboard includes outer transparent waterproof paper 1, corrugated paper 3 and inner transparent waterproof paper 4 arranged sequentially from the outside to the inside, through the outer transparent waterproof paper 1 and the inner transparent waterproof paper The paper 4 makes the box body have a certain waterproof function. Between the outer transparent waterproof paper 1 and the corrugated paper 3, there is a moisture-sensitive color-changing film 2 formed by spraying a moisture-sensitive color-changing compound reagent. The moisture-sensitive color-changing film 2 includes phenolic resin and anhydrous ethanol. , Calcium carbonate, color changing agent, color developing agent, hygroscopic agent, antioxidant and film forming aid, the color changing agent includes purple sweet potato and ethanol solution. The present invention uses spray film forming method t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com