An automatic scribing device

An automatic scribing and driving shaft technology, applied in the field of machinery, can solve the problems that the device cannot withstand the impact force, beating, judge the reliability of the roller, etc., and achieve the effect of stable and reliable scribing, good conveying, and solving the effect of external splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

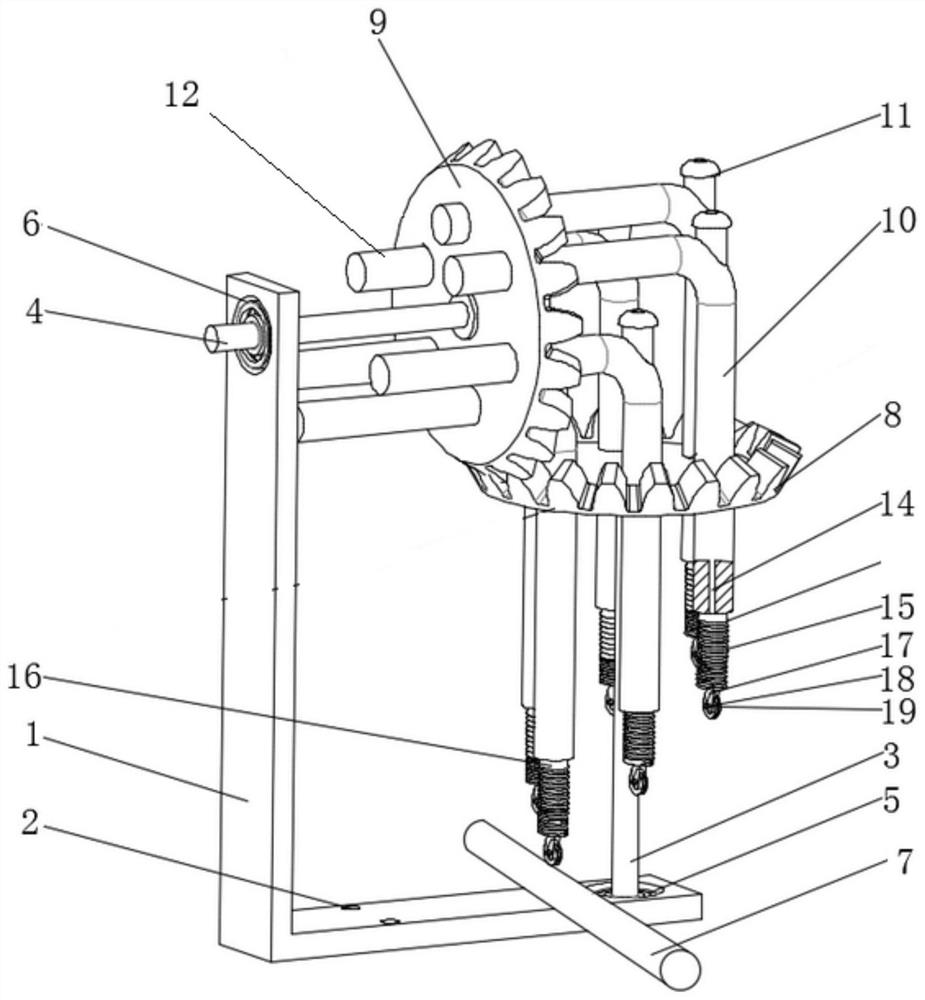

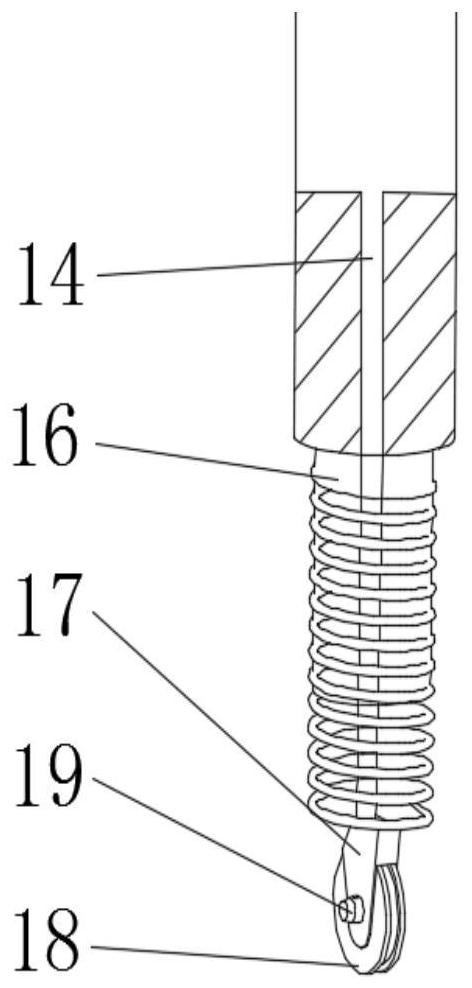

[0018] Such as figure 1 , 2 As shown, an automatic scribing device includes a bracket, a positioning and orientation matching mechanism and an ink outlet mechanism. The bracket includes a vertical plate 1 and a bottom plate 2 that are perpendicular to each other; 4. Bevel gear one 8 and bevel gear two 9, one end of the drive shaft 3 is installed on the base plate 2 through the bearing one 5, and the other end of the drive shaft 3 is fixedly installed at the center of the bevel gear one 8, so One end of the driven shaft 4 is installed on the vertical plate 1 through the bearing 2 6, and the other end of the driven shaft 3 is fixedly installed in the center of the bevel gear 2 9, and the bevel gear 1 8 meshes with the bevel gear 2 9, Bevel gear one 8 and bevel gear two 9 are respectively provided with six mounting holes uniformly distributed along the circumference; the ink outlet mechanism includes an ink bottle 10, an ink outlet head and a positioning rod 12, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com