Method for preparing multi-grain scale magnesium alloy sheet by non-uniform section rolling method

A non-uniform, magnesium alloy technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of poor heat resistance, magnesium alloy strength and toughness, etc., to retain heat resistance, improve strength and The effect of plasticity and good marketing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Taking the rare earth magnesium alloy GW103K as an example, a detailed implementation is given. The following embodiments involve three steps including: non-uniform section plate forming, homogenizing annealing and multi-pass plate rolling, wherein:

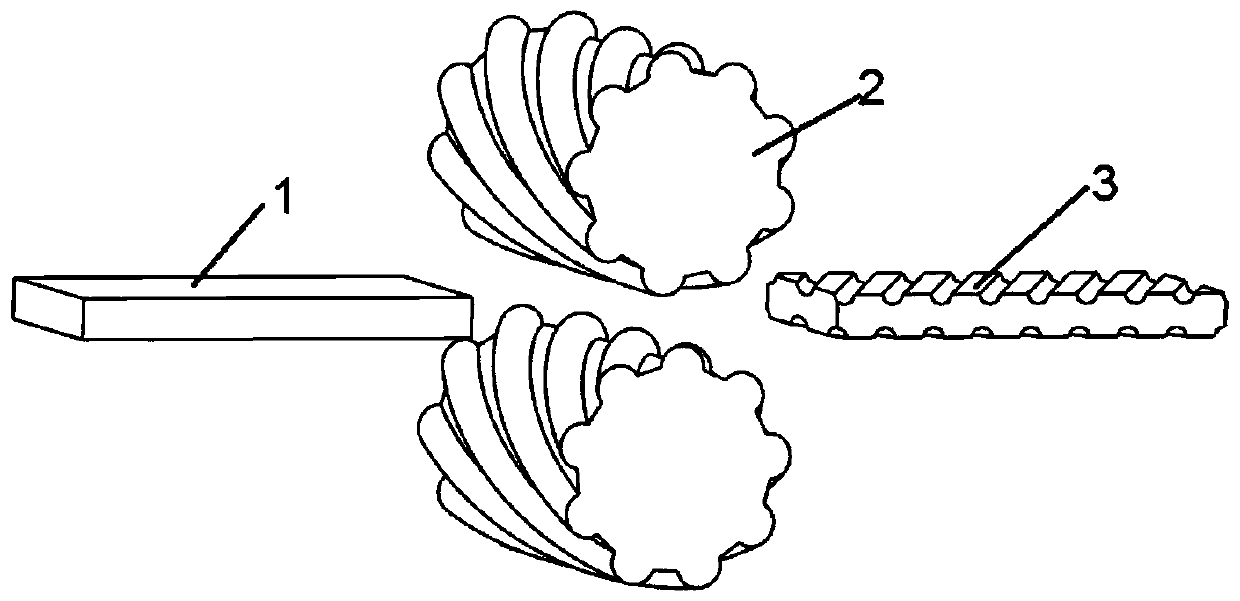

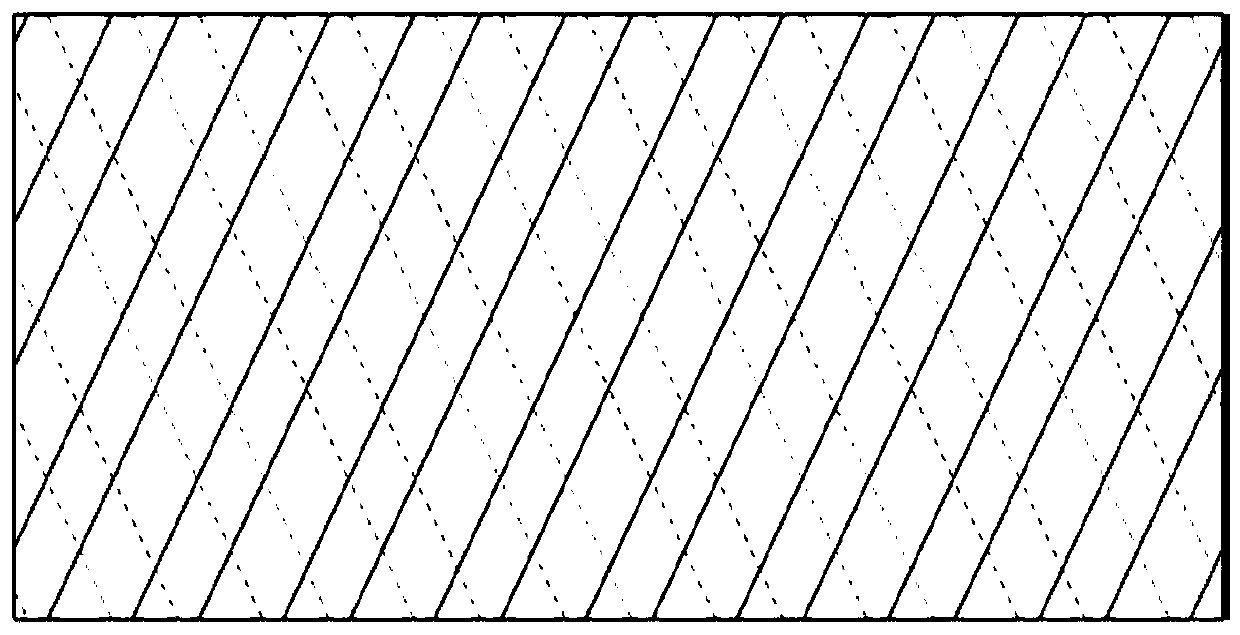

[0035] Step 1: Sheet forming with non-uniform cross-section, such as figure 1 As shown, before rolling, the GW103K magnesium alloy plate 1 is put into a vacuum heat treatment furnace and heated to 330°C, and kept for 10 minutes. After taking it out, the original GW103K magnesium alloy plate 1 is rolled with a semicircular pattern roll 2 to obtain Plates of non-uniform cross-section3, such as figure 2 As shown, the upper and lower surfaces form a cross pattern.

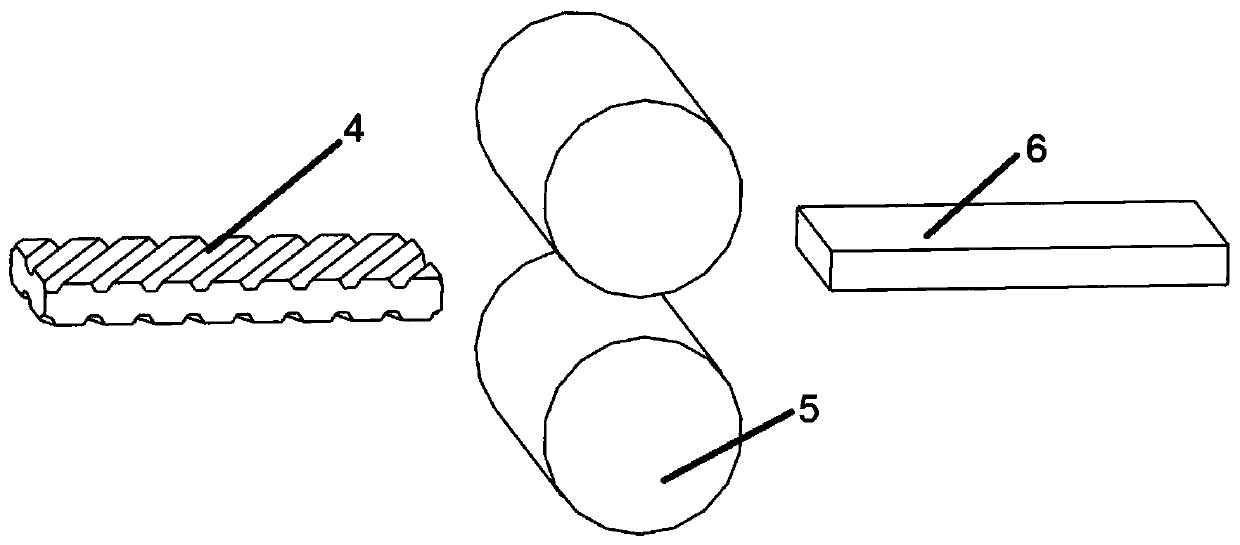

[0036] Step 2: Annealing Annealing, put the GW103K magnesium alloy non-uniform cross-section plate 3 obtained in Step 1 into a vacuum heat treatment furnace, keep it at 325°C for 1 hour, so that the grains become uniform without excessive growth of the grains, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com