Breakdown-resistant power cable

A power cable, anti-breakdown technology, applied in the direction of power cables, insulated cables, cables with shielding/conducting layers, etc., can solve the problem of affecting the anti-breakdown effect of cables, uniform dispersion of graphene, graphene and polymer matrix. Tolerance is poor and other problems, to achieve excellent thermal properties, promote dispersion, improve the effect of breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

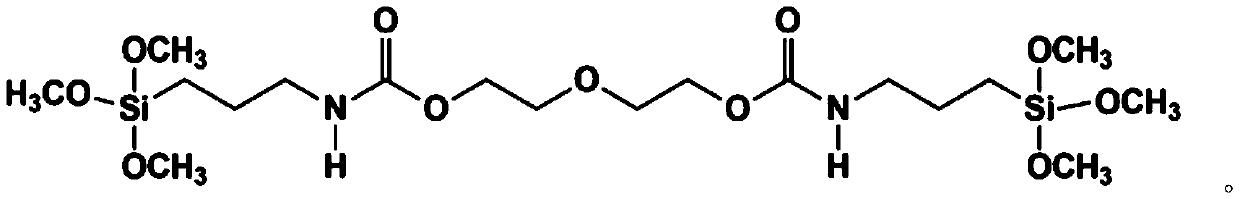

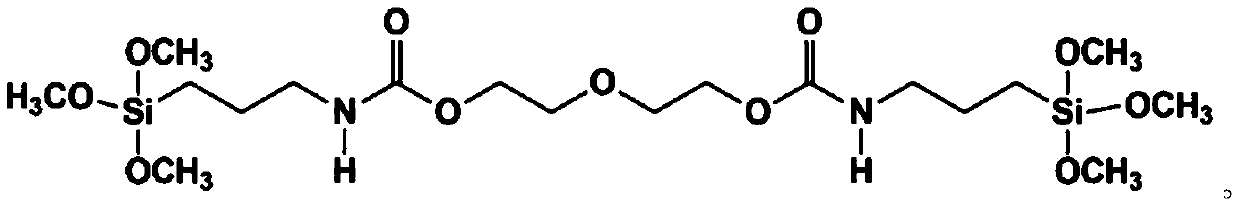

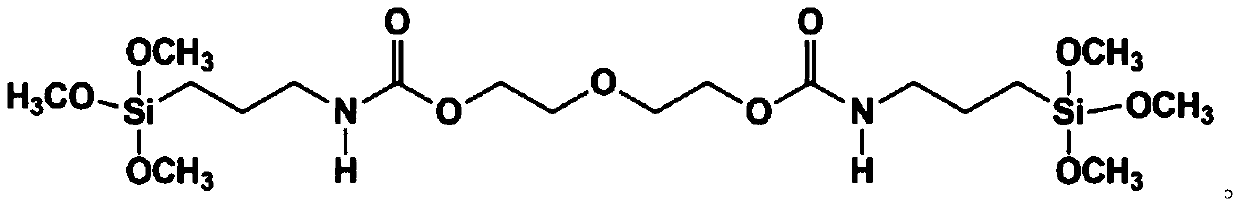

Image

Examples

Embodiment 1

[0035] A breakdown-resistant power cable, comprising a conductor, the outer side of the conductor is wrapped with a conductor shielding layer, the outer side of the conductor shielding layer is wrapped with an insulating rubber layer, the outer side of the insulating rubber layer is a wrapping layer, and the outer side of the wrapping layer is It is a rubber protective layer, and the conductor shielding layer is a graphene shielding material. There is a waterproof layer between the wrapping layer and the rubber protection layer. The conductor is a copper conductor. The preparation process of described graphene shielding material comprises the steps:

[0036] S1 configures H with a volume ratio of 9:1 2 SO 4 / H 3 PO 4 Mixed acid, add the mixed acid to the mixture of flake graphite / potassium permanganate with a mass ratio of 1:7, and exotherm to 35°C;

[0037] S2 was heated to 50°C and stirred, the product was cooled to room temperature, poured into ice water, and then hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com