Thin coal layer supporting device with variable-frequency constant-pressure control system

A control system, frequency conversion and constant pressure technology, applied in pillars/brackets, mining equipment, earthwork drilling and mining, etc., can solve the problems of reducing the safety factor of support equipment, increasing mechanical wear, shortening service life, etc., and achieves obvious energy-saving effect. Increased height space and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

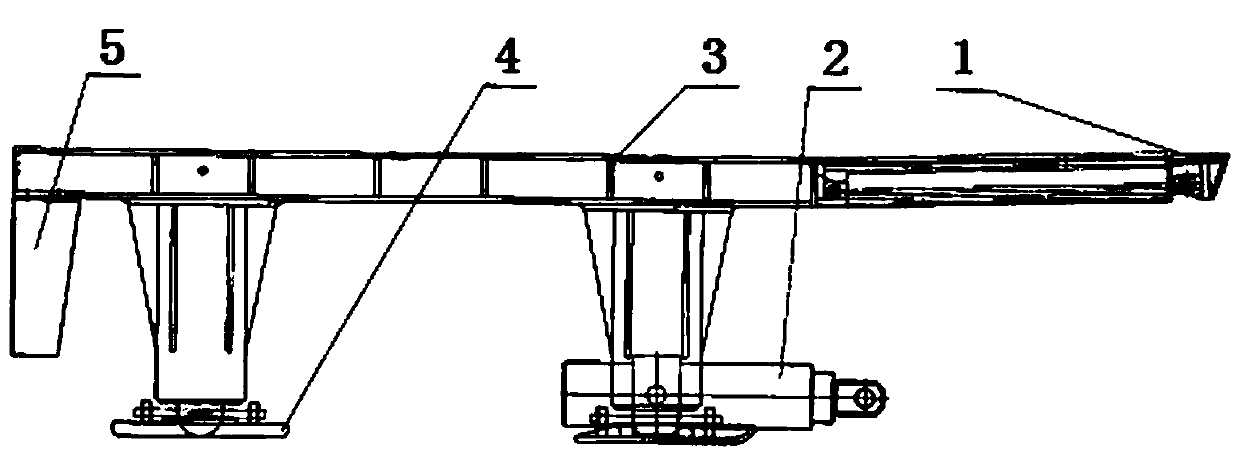

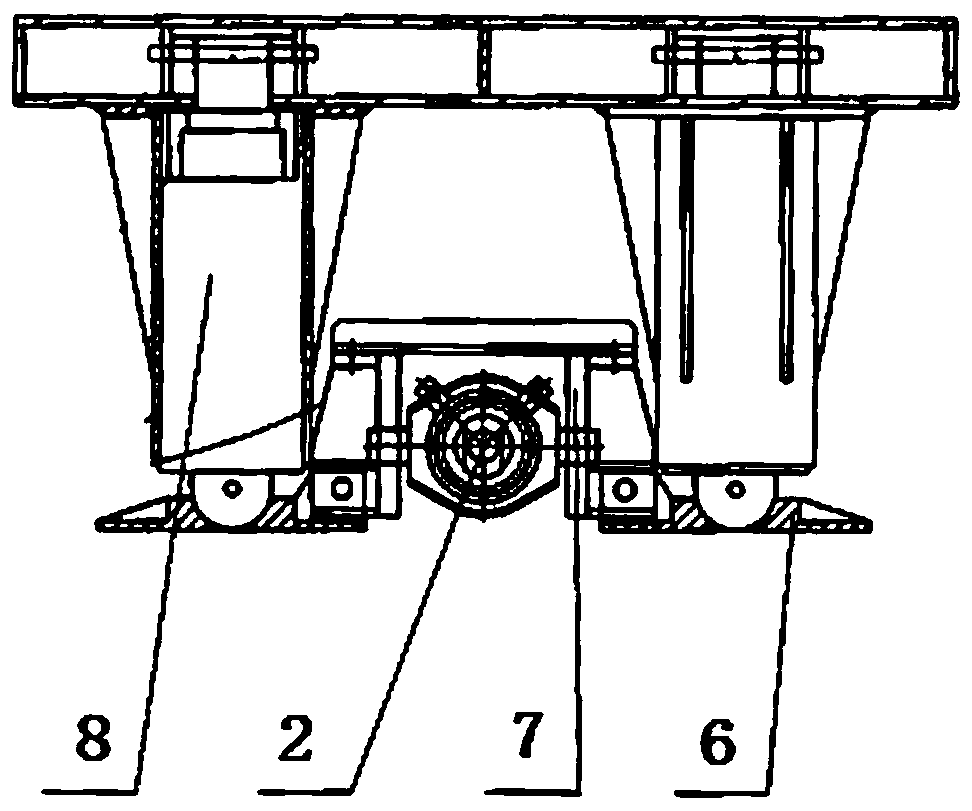

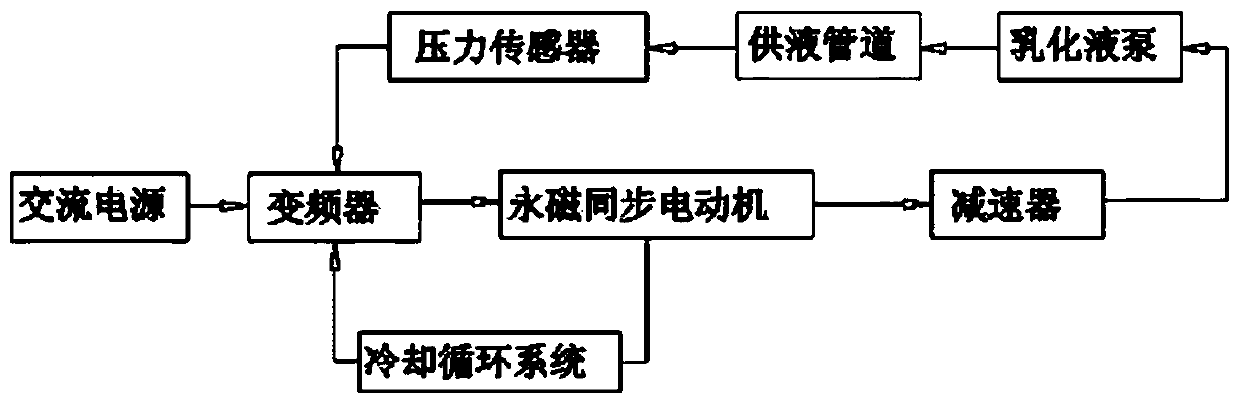

[0017] The specific structure of the present invention will be described in detail according to the accompanying drawings. The thin coal seam support device with a frequency conversion constant pressure control system includes a top beam 3 and an emulsion pump frequency conversion constant pressure control system. 5. Among them, the lower part of the top beam 3 is fixed with four guide cylinders. The four guide cylinders are divided into front and rear groups. The two guide cylinders in each group are arranged symmetrically. A double telescopic column 8 is installed in each guide cylinder. The double telescopic columns 8 are divided into front and rear groups. The upper ends of the double telescopic columns 8 extend into the top beam 3 to withstand the upper roof of the top beam 3, and are hinged with the top beam 3 through pin shafts. The lower spherical surfaces of the double telescopic columns 8 Hinged on the base, the base is separated into a front column base 6 and a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com