House and vehicle integrated type rest room and manufacturing technology thereof

A toilet and integrated technology, which is applied in the field of integrated toilets and manufacturing processes of RVs, can solve the problems of many glued seams, loose connections, and easy deformation of the integrated metal frame welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

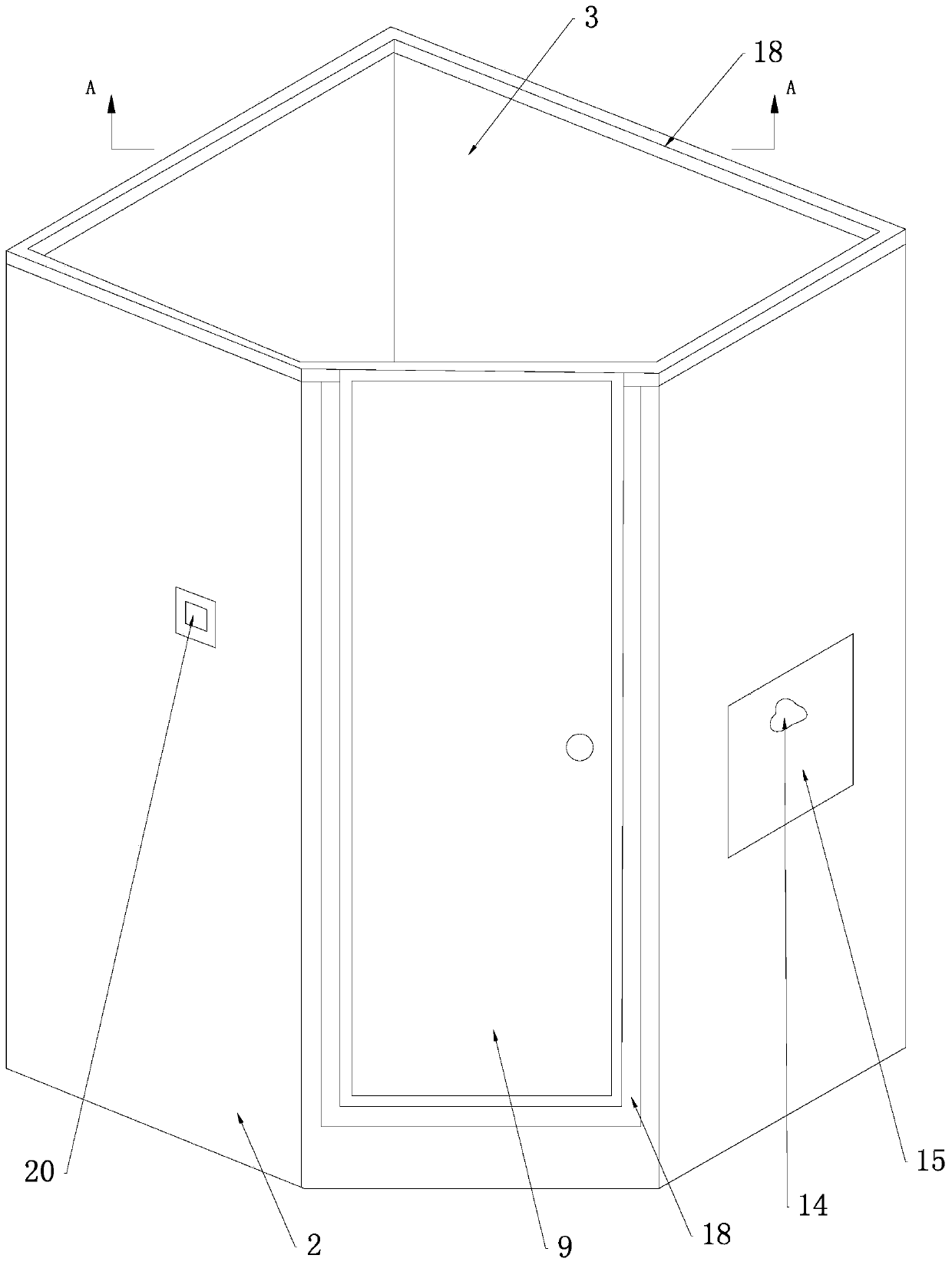

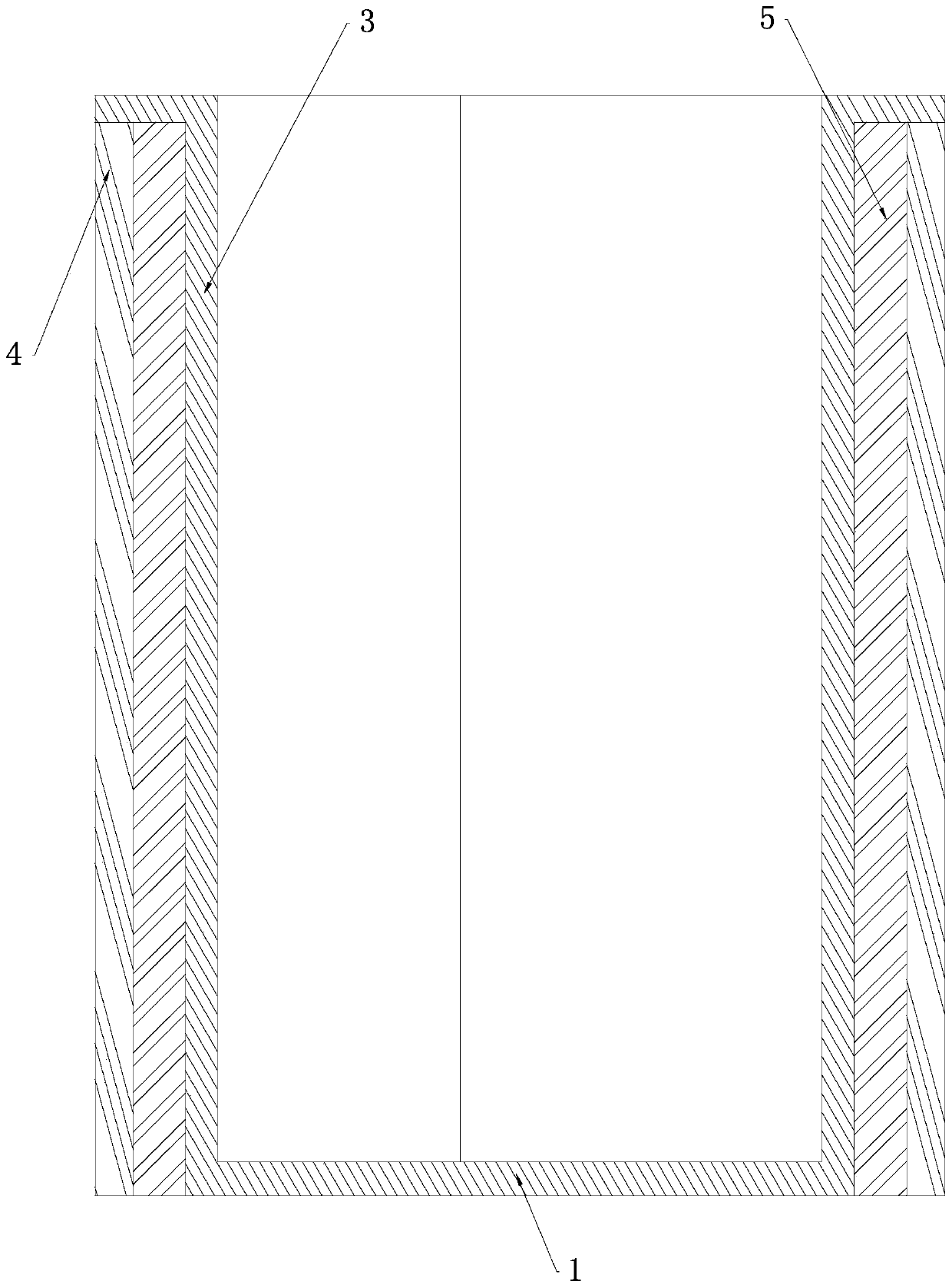

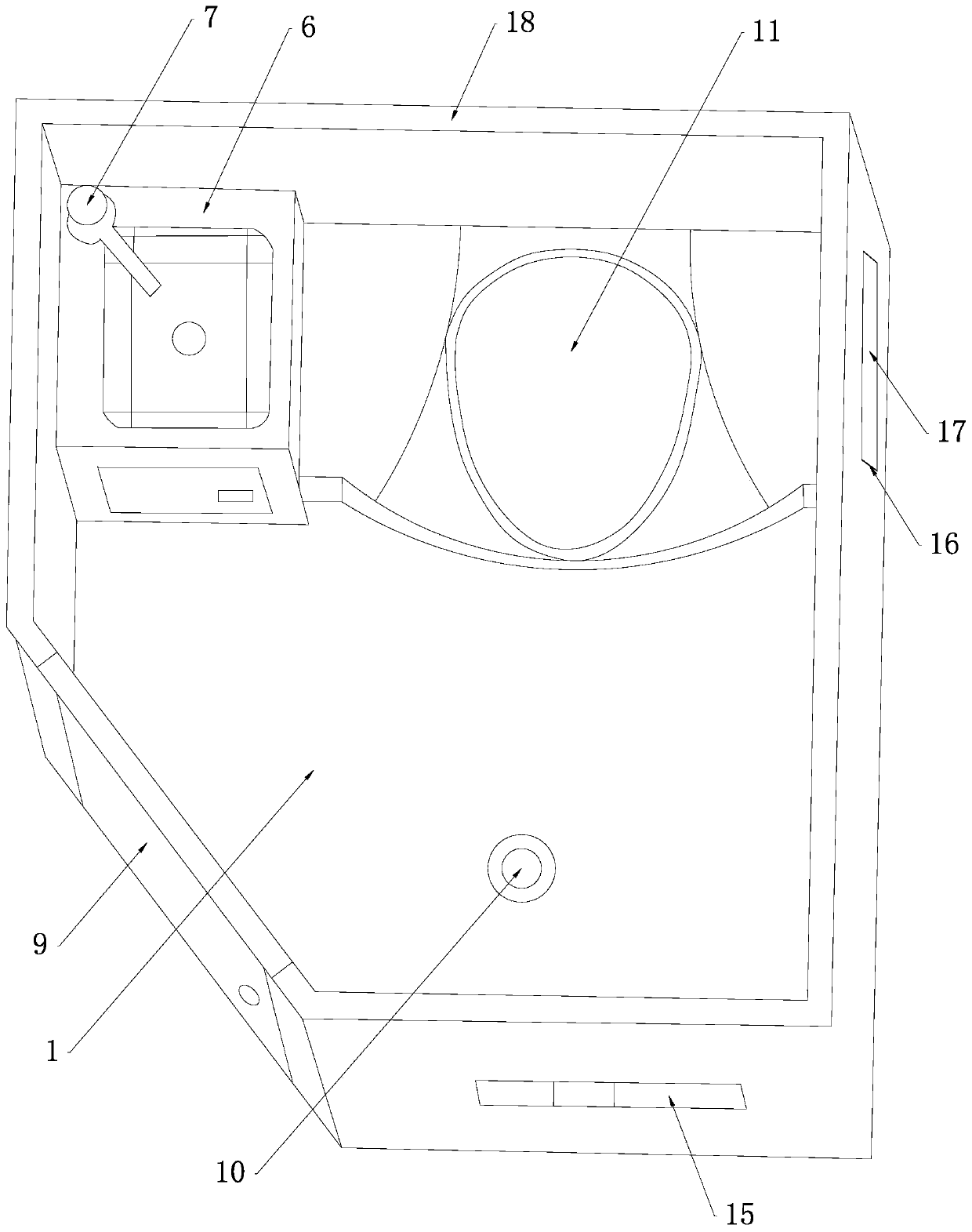

[0041] Such as Figure 1-4 As shown, the RV integrated toilet includes an integrated base plate 1 and side wall 2, the base plate forms the floor in the toilet, and the side wall includes an inner plate 3, an outer plate 4 and a wall between the inner plate and the outer plate. The space is filled; the inner panel and the bottom panel are integrally formed; the top of the inner panel is turned outward at right angles, and the bottom surface of the inner panel is fixedly connected with the top of the outer panel.

[0042] In the filling space, a filling plate 5, a threading pipe, and a mounting part fixing plate are arranged. The filling board is a foam board; the threading pipe is used for arranging wires or water pipes; the mounting part fixing plate is a metal plate, and the metal plate is used to fix other mounting parts in the bathroom, such as faucets and showers in the bathroom Fixing of mounting parts such as racks.

[0043] A washbasin 6 integrally formed with the in...

Embodiment 2

[0064] Such as Figure 5 As shown, the structural diagram is more precisely another embodiment of the connection between the RV integrated toilet and the RV roof. The RV integrated toilet includes a bottom plate 1 and a side wall 2 integrally arranged, the bottom plate forms the floor in the toilet, and the side wall includes an inner panel 3, an outer panel 4 and a filling space between the inner panel and the outer panel; The inner panel and the bottom panel are integrally formed; the top of the inner panel is turned outward at right angles, and the bottom surface of the inner panel is fixedly connected with the top of the outer panel.

[0065] In the filling space, a filling plate 5, a threading pipe, and a mounting part fixing plate are arranged. The filling board is a foam board; the threading pipe is used for arranging wires or water pipes; the mounting part fixing plate is a metal plate, and the metal plate is used to fix other mounting parts in the bathroom, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com