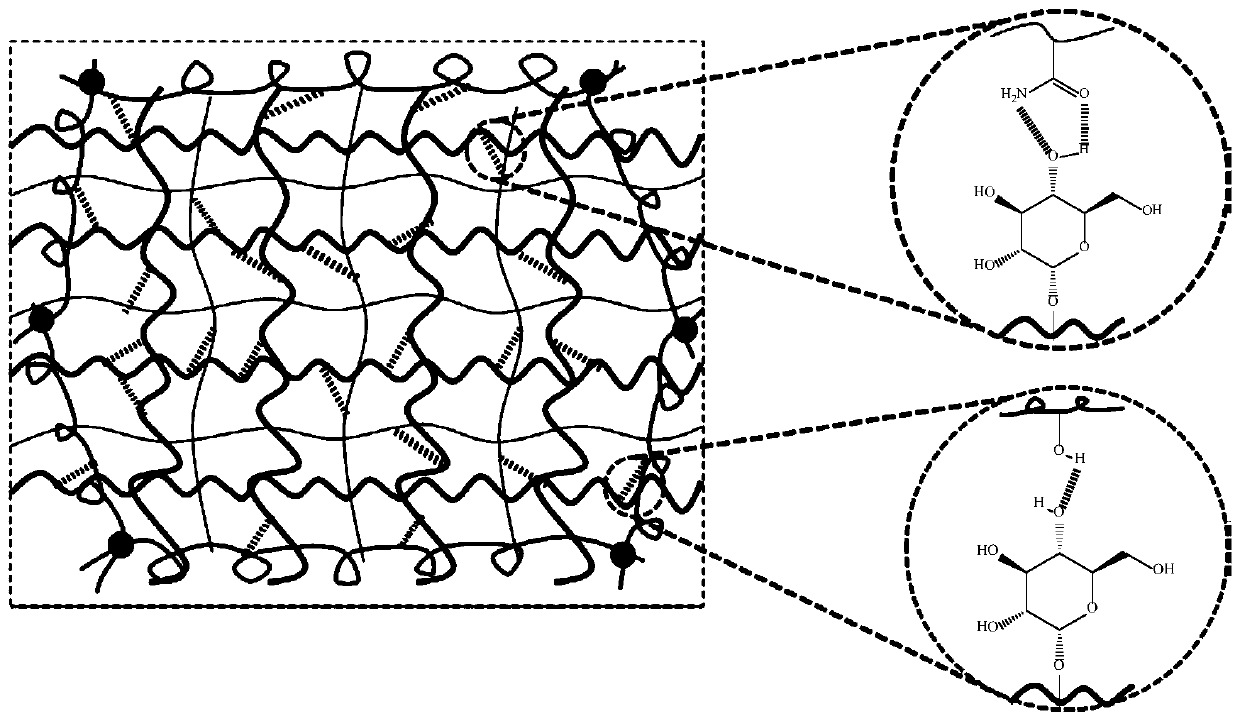

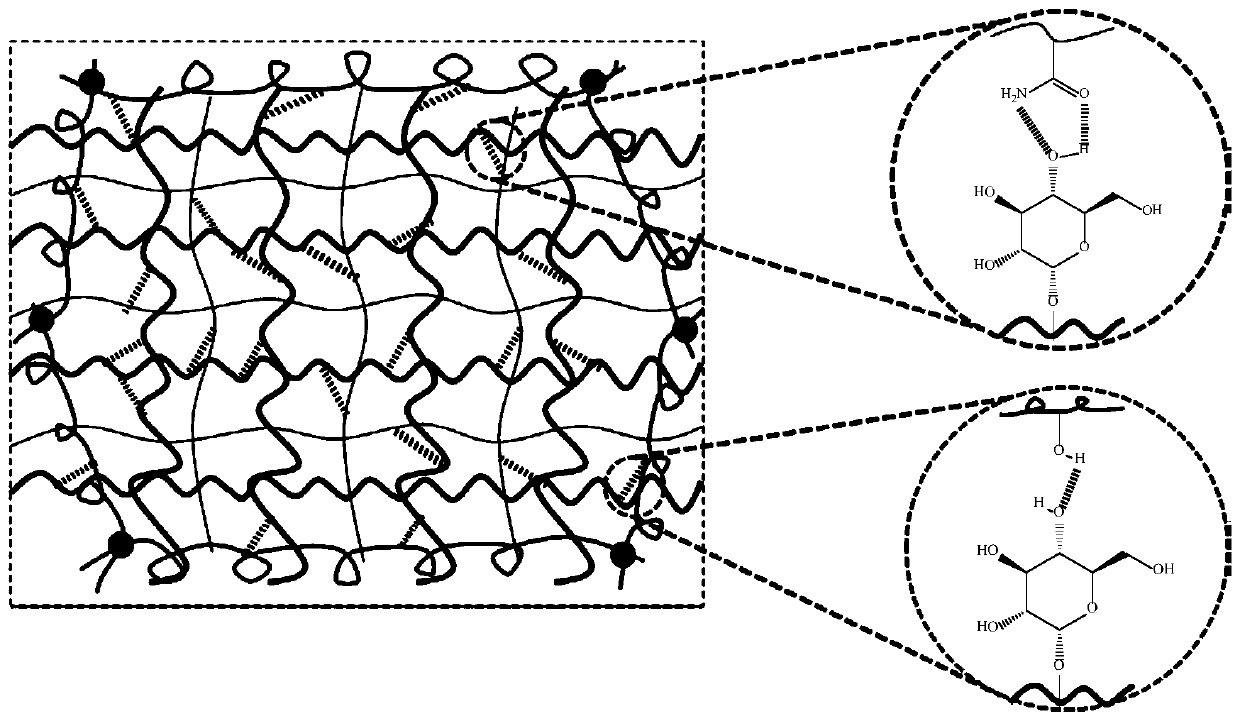

Preparation method of high-strength and high-adhesion branched starch composite hydrogel with strong hydrogen bonding effect

A composite hydrogel and pullulan technology, which is applied in the field of polymer materials, can solve problems such as reduction, uneven gel crosslinking, and unstable performance, and achieve simple and easy-to-control processes, uniform hydrogel structure, excellent The effect of adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1): Weigh 3.0000g of Amy (100mg / mL) and 0.9278g of PVA (3wt%) into a three-necked flask, add 30mL of deionized water, and stir in a water bath at 100°C for 1.5 hours to obtain a uniform mixed solution.

[0030] Step 2): Weigh 17.0592g AAm (8mol / L) and 0.0351g KA (0.008mol / L) respectively into the mixed solution of step 1), stir in a water bath at 60°C for 30 minutes under the condition of avoiding light, and prepare A mixed solution of 100 mg / mL of Amy, 3 wt % of PVA relative to the solvent deionized water, and 8 mol / L of AAm was obtained.

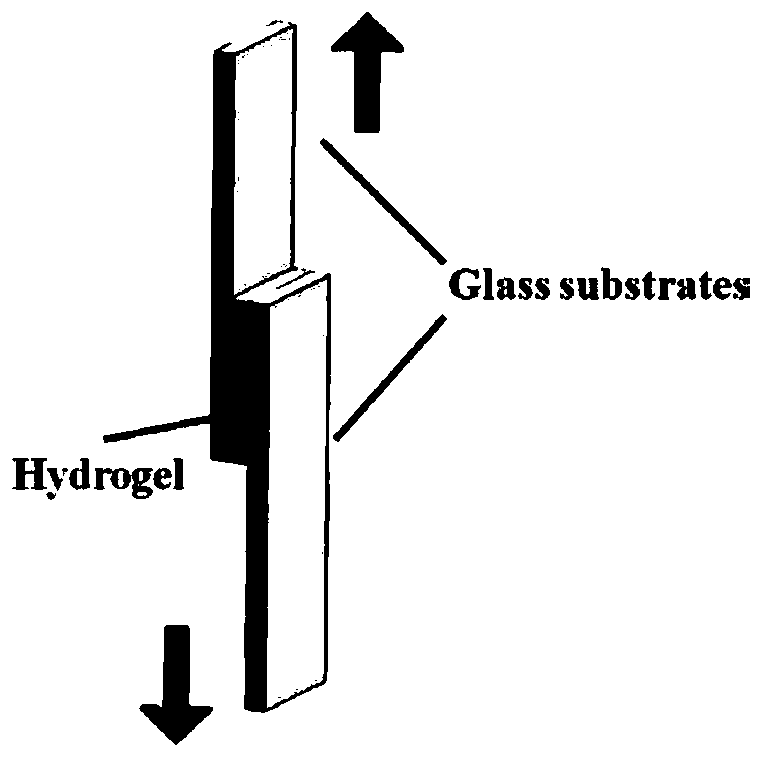

[0031] Step 3): inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, and place it under an ultraviolet light at 20 cm for 5-7 hours to obtain a pre-polymerized Amy hydrogen-bonded cross-linked PAAm hydrogel.

[0032] Step 4): The pre-polymerized hydrogel obtained in step 3) was frozen in a refrigerator at -20°C for 20 hours, and then thawed at 25°C for 4 hours to obtain a high-streng...

Embodiment 2

[0036] Step 1): Weigh 4.5000g of Amy (150mg / mL) and 0.9278g of PVA (3wt%) into a three-necked flask, then add 30mL of deionized water, and stir in a water bath at 100°C for 1.5 hours to obtain a uniform mixed solution.

[0037] Step 2): Weigh 17.0592g AAm (8mol / L) and 0.0351g KA (0.008mol / L) respectively into the mixed solution of step 1), stir in a water bath at 60°C for 30 minutes under the condition of avoiding light, and prepare A mixed solution of 150 mg / mL of Amy, 3 wt % of PVA and 8 mol / L of AAm was obtained.

[0038] Step 3): inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, and place it under an ultraviolet light at 20 cm for 5-7 hours to obtain a pre-polymerized Amy hydrogen-bonded cross-linked PAAm hydrogel.

[0039] Step 4): The pre-polymerized hydrogel obtained in step 3) was frozen in a refrigerator at -20°C for 20 hours, and then thawed at 25°C for 4 hours to obtain a high-strength, high-adhesion Amy composite PAAm...

Embodiment 3

[0043] Step 1): Weigh 3.0000g of Amy (100mg / mL) and 1.2766g of PVA (4wt%) into a three-necked flask, then add 30mL of deionized water, and stir in a water bath at 100°C for 2.0 hours to obtain a uniform mixed solution.

[0044] Step 2): Weigh 21.3240g AAm (10mol / L) and 0.0438g KA (0.010mol / L) respectively into the mixed solution of step 1), stir in a water bath at 60°C for 30 minutes under the condition of avoiding light, and prepare A mixed solution of 100 mg / mL of Amy, 4 wt % of PVA and 10 mol / L of AAm was prepared.

[0045] Step 3): inject the mixed solution obtained in step 2) into a glass mold under light-shielding conditions, and place it under an ultraviolet light at 20 cm for 5-7 hours to obtain a pre-polymerized Amy hydrogen-bonded cross-linked PAAm hydrogel.

[0046] Step 4): The pre-polymerized hydrogel obtained in step 3) was frozen in a refrigerator at -20°C for 20 hours, and then thawed at 25°C for 4 hours to obtain a high-strength, high-adhesion Amy composite PA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com