Engine room heat shield and automobile

A technology for heat shields and cabins, which is applied to vehicle components, transportation and packaging, superstructure sub-assemblies, etc., can solve the problems of reducing the service life of the rear sealing strip 5 of the front cover and the wiper trim 3, so as to reduce heat damage, slowing down the rate of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

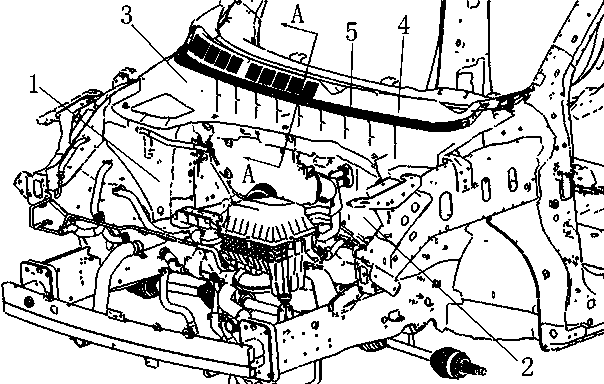

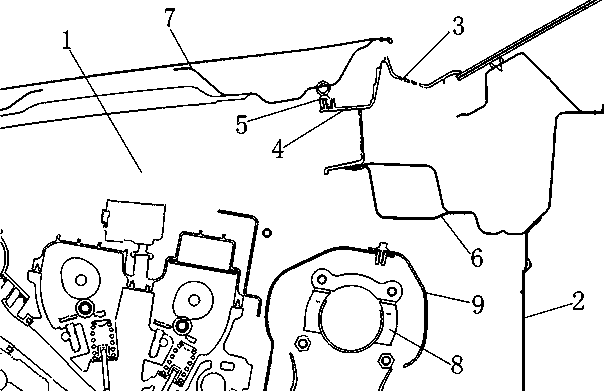

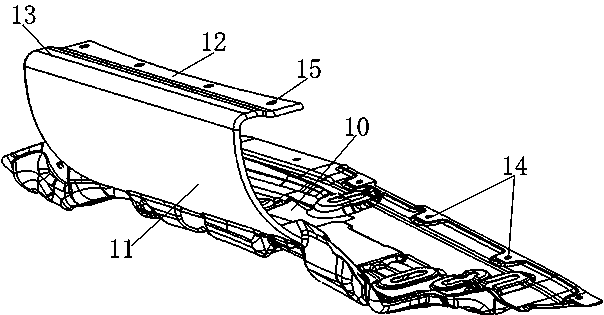

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] like image 3 and Figure 4 The cabin heat shield shown includes a bottom plate portion 10 connected to the rear wall 2 of the engine nacelle 1, a sloping plate portion 11 whose lower edge is connected to the front edge of the bottom plate portion 10, and from the sloping plate portion 11. The upper edge is a flange 12 extending backwards. The flange 12 is used to connect with the sealing strip installation platform 4 on the wiper trim 3 , and the sloping plate portion 11 gradually extends upwards from the rear to the front. With the above-mentioned technical solution, the bottom plate part 10 plays the role of heat insulation, and the sloping plate part 11 plays the role of heat insulation and guiding the high-temperature air; the high-temperature air formed by the turbocharger is guided by the sloping plate part 11 , can reduce the flow of hot air to the front co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com