Vertical magnetic glue mixing device

A magnetic and glue mixing technology, applied in mixers, mixing methods, dissolution and other directions, can solve problems such as adhesive leakage and equipment contamination, and achieve the effects of improving stability, reducing labor intensity and improving labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below in conjunction with the accompanying drawings and specific examples, and these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

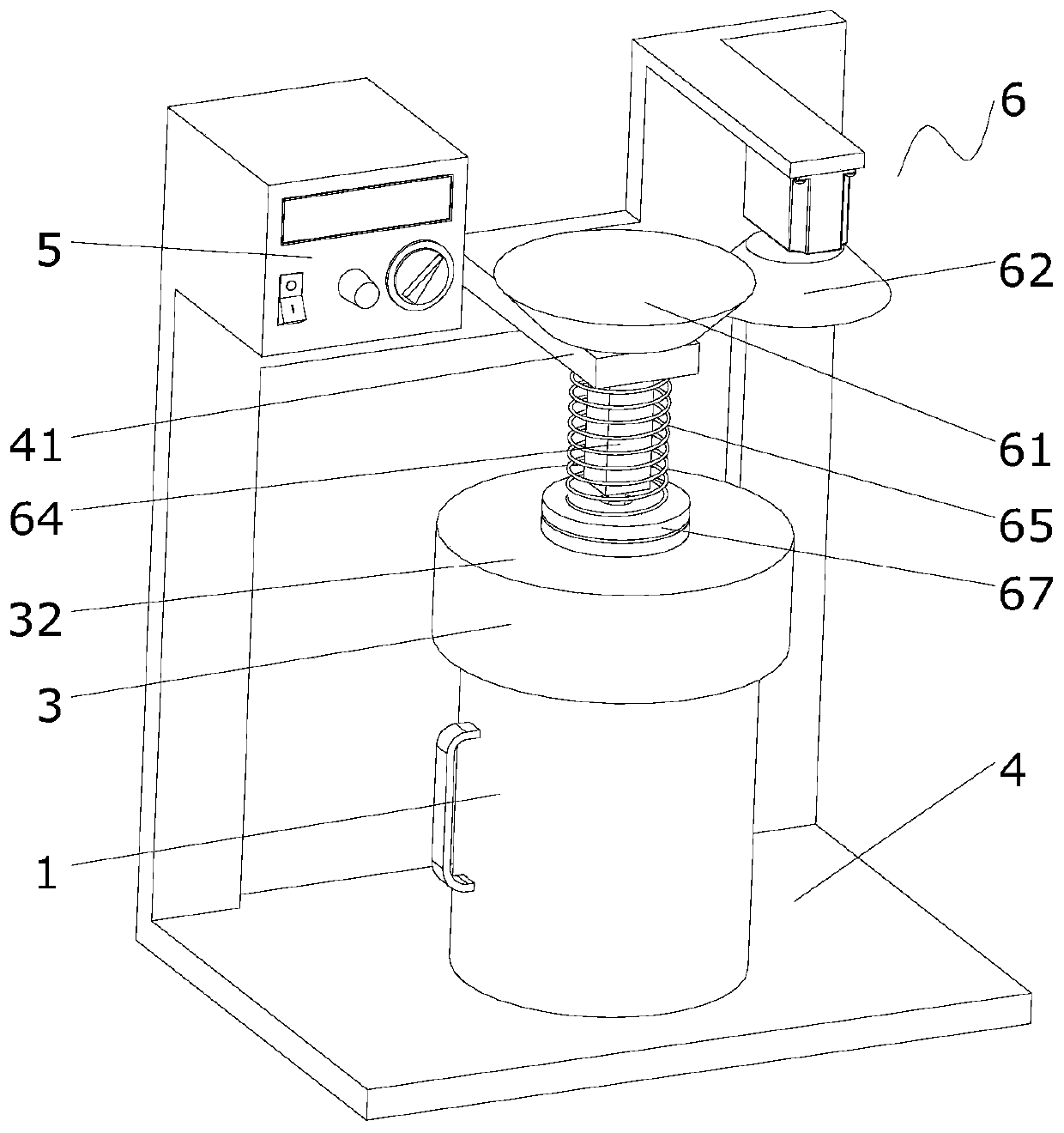

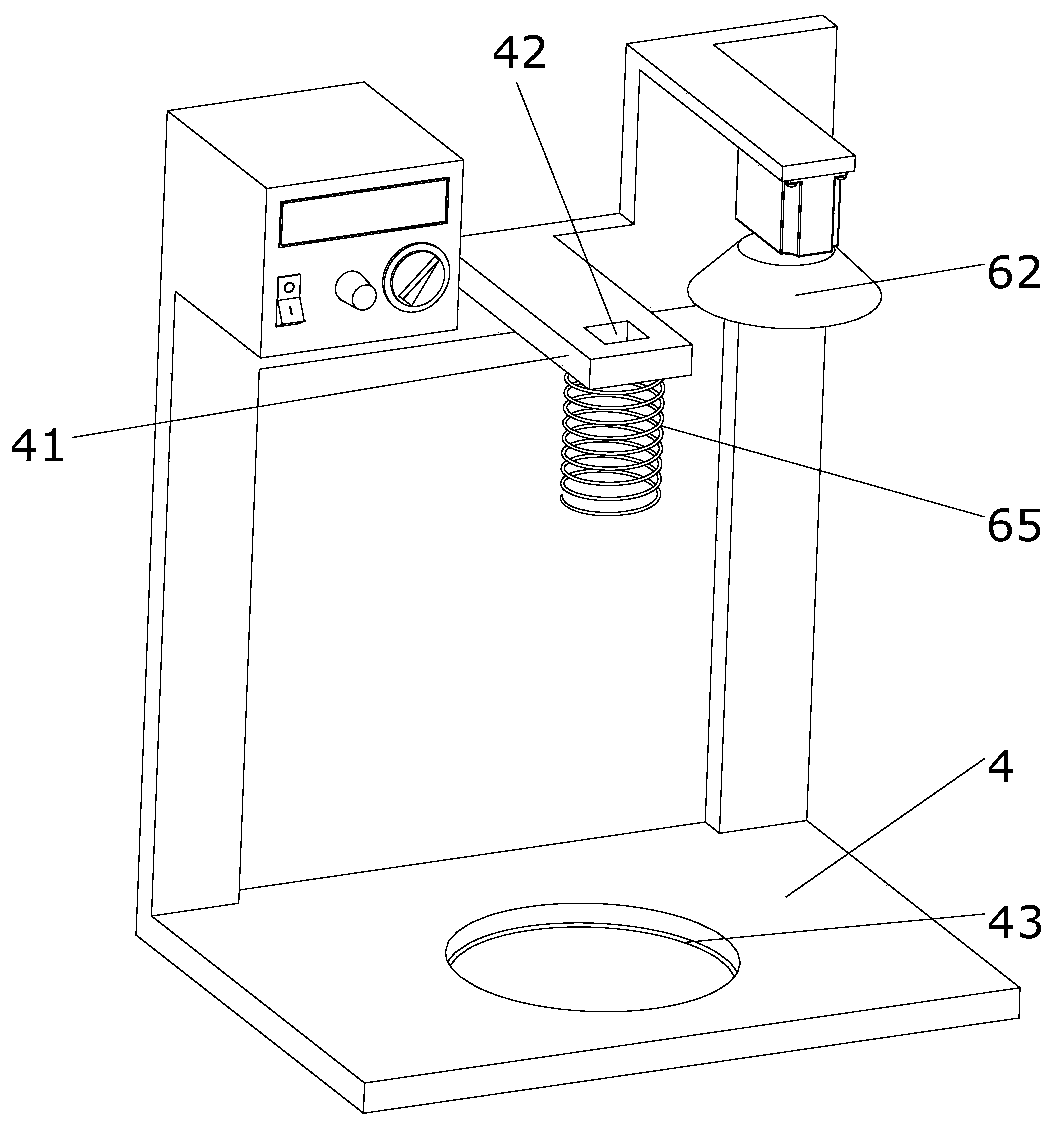

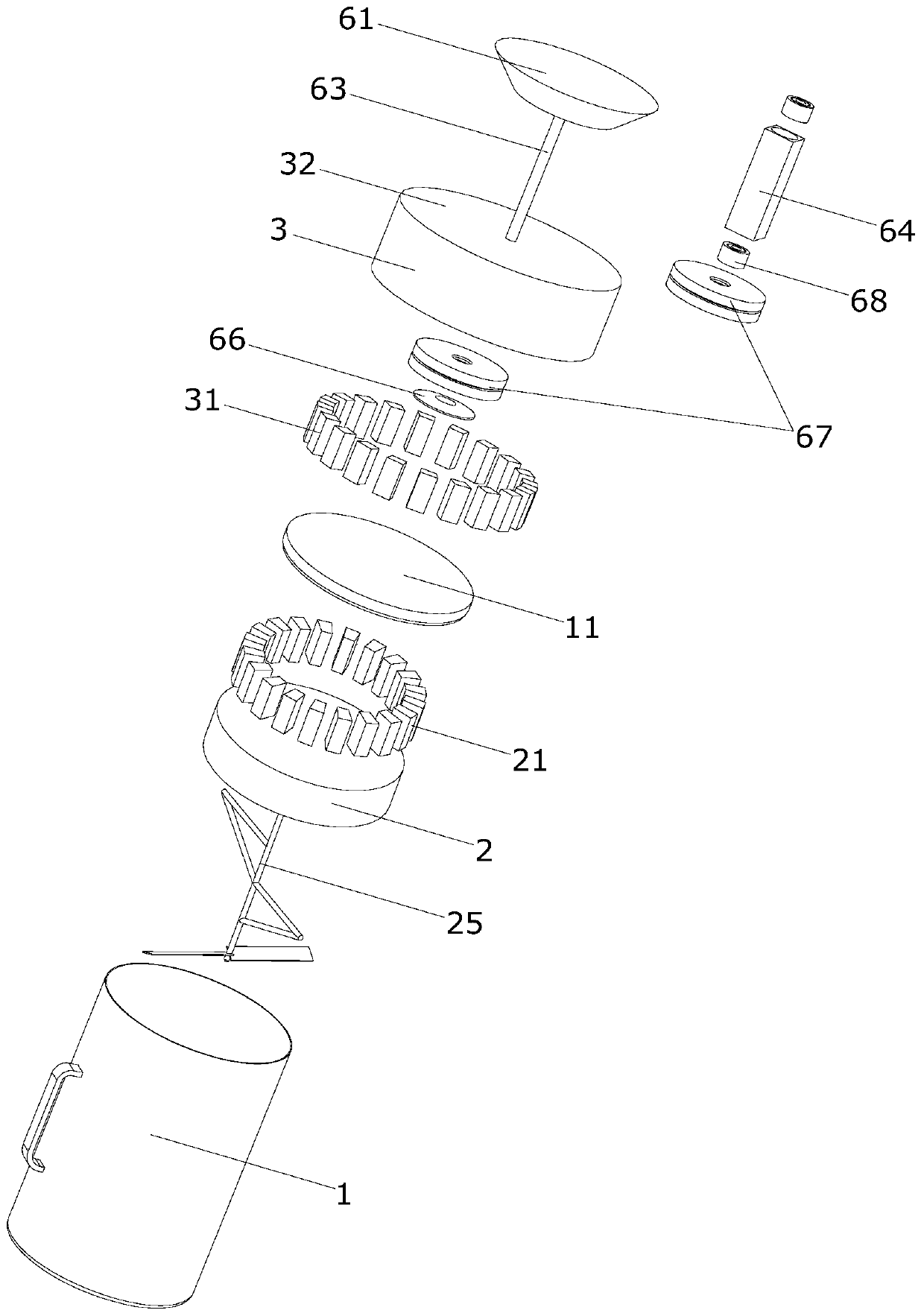

[0027] A vertical magnetic mixing device, as attached Figure 1~3 As shown, it includes a mixing drum 1 , a stirring claw 2 , a driving ring 3 , a base 4 , a control box 5 , and a driving mechanism 6 .

[0028] The mixing drum 1 is vertically placed on its axis, and an openable opening is provided on the mixing drum for taking and placing glue and stirring claws. At least one of the two ends of the mixing drum can be set as an end cover 11 as an openable opening, such as an attached image 3 As shown in , the upper end of the mixing drum is used as the end cover 11, and the bottom of the mixing drum is installed on the base 4.

[0029] The base 4 is provided with a cantilever 41, and the driving ring 3 is arranged ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com