Supercapacitor electrode material, and preparation method and application thereof

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of affecting the performance of capacitors, increasing the weight of working electrodes, and bulky capacitors, and achieves good electrochemical performance. Capacitance performance, the effect of excellent specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

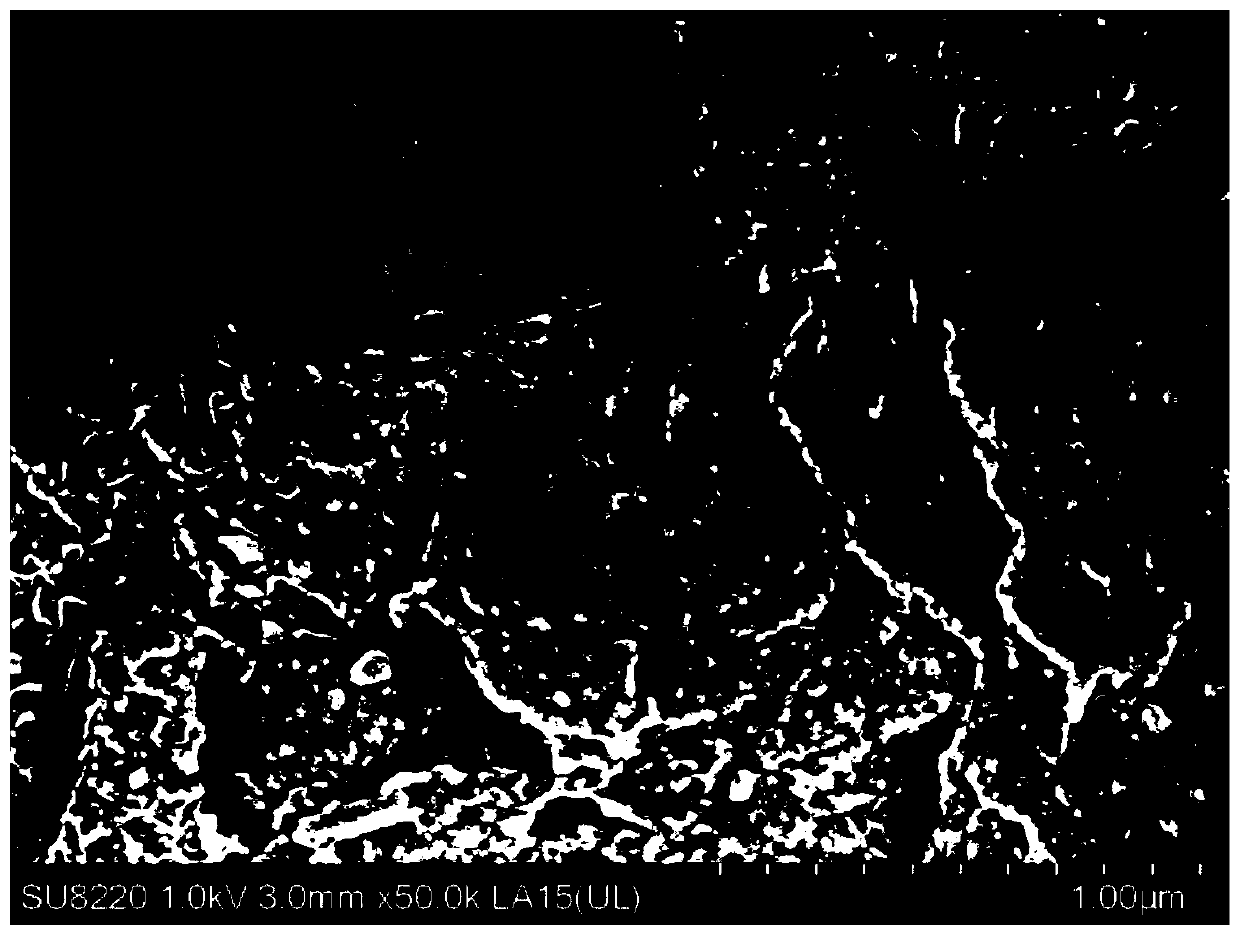

Image

Examples

Embodiment 1

[0032] The preparation method of the present embodiment 1 metal hydroxide film material comprises the following steps:

[0033] Accurately weigh 1 mmol of NiCl 2 ·6H 2 O, add 25mL of water, put in a magnet and stir at room temperature for 10min, until the NiCl 2 ·6H 2 After O was completely dissolved, 9 mmol of triethanolamine was added dropwise, and after stirring for 20 min, the obtained mixture was transferred to a 50 mL stainless steel reactor for hydrothermal reaction. The hydrothermal temperature was 180 °C and the hydrothermal time was 12 h. After the reaction, it was taken out and cooled to room temperature, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a metal hydroxide thin film material.

Embodiment 2

[0035] The preparation method of the present embodiment 2 metal hydroxide film material comprises the following steps:

[0036] Accurately weigh 1 mmol of NiCl 2 ·6H 2 O, add 25mL of water, put in a magnet and stir at room temperature for 10min, until the NiCl 2 ·6H 2 After O was completely dissolved, 12 mmol triethanolamine was added dropwise, and after stirring for 20 min, the resulting mixture was transferred to a 50 mL stainless steel reactor for hydrothermal reaction. The hydrothermal temperature was 180 °C and the hydrothermal time was 12 h. After the reaction, it was taken out and cooled to room temperature, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a metal hydroxide thin film material.

Embodiment 3

[0038] The preparation method of the present embodiment 3 metal hydroxide film material, comprises the following steps:

[0039] Accurately weigh 1 mmol of NiCl 2 ·6H 2 O, add 25mL of water, put in a magnet and stir at room temperature for 10min, until the NiCl 2 ·6H 2 After O was completely dissolved, 9 mmol of triethanolamine was added dropwise, and after stirring for 20 min, the obtained mixture was transferred to a 50 mL stainless steel reactor for hydrothermal reaction. The hydrothermal temperature was 180 °C and the hydrothermal time was 8 h. After the reaction, it was taken out and cooled to room temperature, washed by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a metal hydroxide thin film material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com