An easy-to-wear radiation-proof medical isolation gown

A technology of isolation clothing and radiation protection, applied in the field of protective isolation clothing, can solve the problems of unsatisfactory radiation protection effect, low radiation protection effect, difficult operation and price comparison, etc., so as to avoid difficult operation behind, strong hygroscopicity, and radiation resistance effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

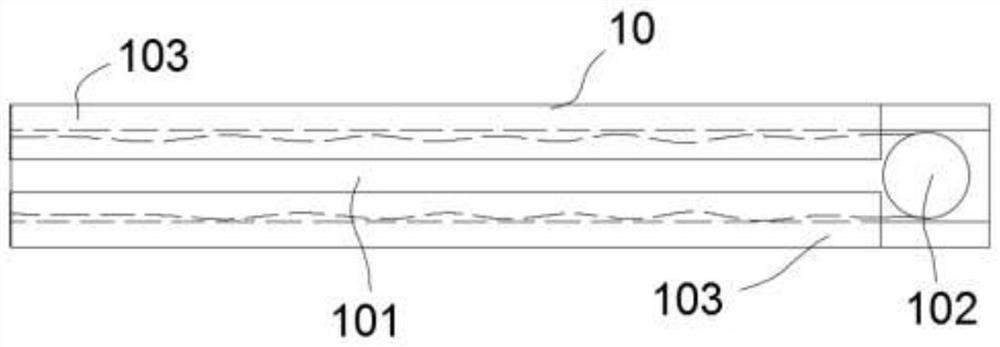

[0036] like Image 6 As shown, the fabric of the medical isolation gown is a multi-layer structure. From top to bottom, it is the protective layer 11, the radiation protection layer 12 and the fabric base layer 13. The protection layer 11, the radiation protection layer 12 and the fabric base layer 13 are bonded by hot pressing. .

[0037] The preparation method of the protective layer 11 is as follows: the polyamide fiber is pad-rolled in the nano-titanium dioxide aqueous dispersion, the temperature is maintained at 45 ° C, and then after cooling down to 34 ° C, the polyethylene terephthalate is mixed with a volume ratio of 1:115. The alcohol ester is added to the aqueous dispersion of nano-titanium dioxide, ultrasonically dispersed for 2 minutes, and the padding time is 15 minutes. The particle size of the nano-titanium dioxide is 10 nm. By changing the temperature and adding the proportion of polyethylene terephthalate, the adhesion of nano-titanium dioxide to the polyamid...

Embodiment 2

[0042] like Image 6 As shown, the fabric of the medical isolation gown is a multi-layer structure. From top to bottom, it is the protective layer 11, the radiation protection layer 12 and the fabric base layer 13. The protection layer 11, the radiation protection layer 12 and the fabric base layer 13 are bonded by hot pressing. .

[0043] The preparation method of the protective layer 11 is as follows: the polyamide fiber is pad-rolled in the nano-titanium dioxide aqueous dispersion, the temperature is maintained at 49° C., and then the temperature is lowered to 35° C., and the polyethylene terephthalate is mixed with a volume ratio of 1:132. Alcohol ester is added to nano-titanium dioxide aqueous dispersion, ultrasonically dispersed for 3 minutes, padding time is 21 minutes, and the particle size of nano-titanium dioxide is 12nm. By changing the temperature and adding the proportion of polyethylene terephthalate, the adhesion of nano-titanium dioxide to the polyamide fiber ...

Embodiment 3

[0048] like Image 6 As shown, the fabric of the medical isolation gown is a multi-layer structure. From top to bottom, it is the protective layer 11, the radiation protection layer 12 and the fabric base layer 13. The protection layer 11, the radiation protection layer 12 and the fabric base layer 13 are bonded by hot pressing. .

[0049] The preparation method of the protective layer 11 is as follows: the polyamide fiber is pad-rolled in the nano-titanium dioxide aqueous dispersion, the temperature is maintained at 52°C, and then the temperature is lowered to 37°C, and the polyethylene terephthalate is mixed with a volume ratio of 1:140. The alcohol ester is added to the aqueous dispersion of nano-titanium dioxide, ultrasonically dispersed for 3 minutes, and the padding time is 25 minutes. The particle size of the nano-titanium dioxide is 15 nm. By changing the temperature and adding the proportion of polyethylene terephthalate, the adhesion of nano-titanium dioxide to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com