Automatic detection device and detection method for content of ammonia nitrogen and nitrite

An ammonia nitrogen nitrite, automatic detection technology, applied in the direction of color/spectral characteristic measurement, analysis through chemical reaction of materials, material analysis through observation of the influence of chemical indicators, etc., can solve the problem of only single detection, etc. problems, to achieve the effect of reducing requirements, improving accuracy, and reducing equipment pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

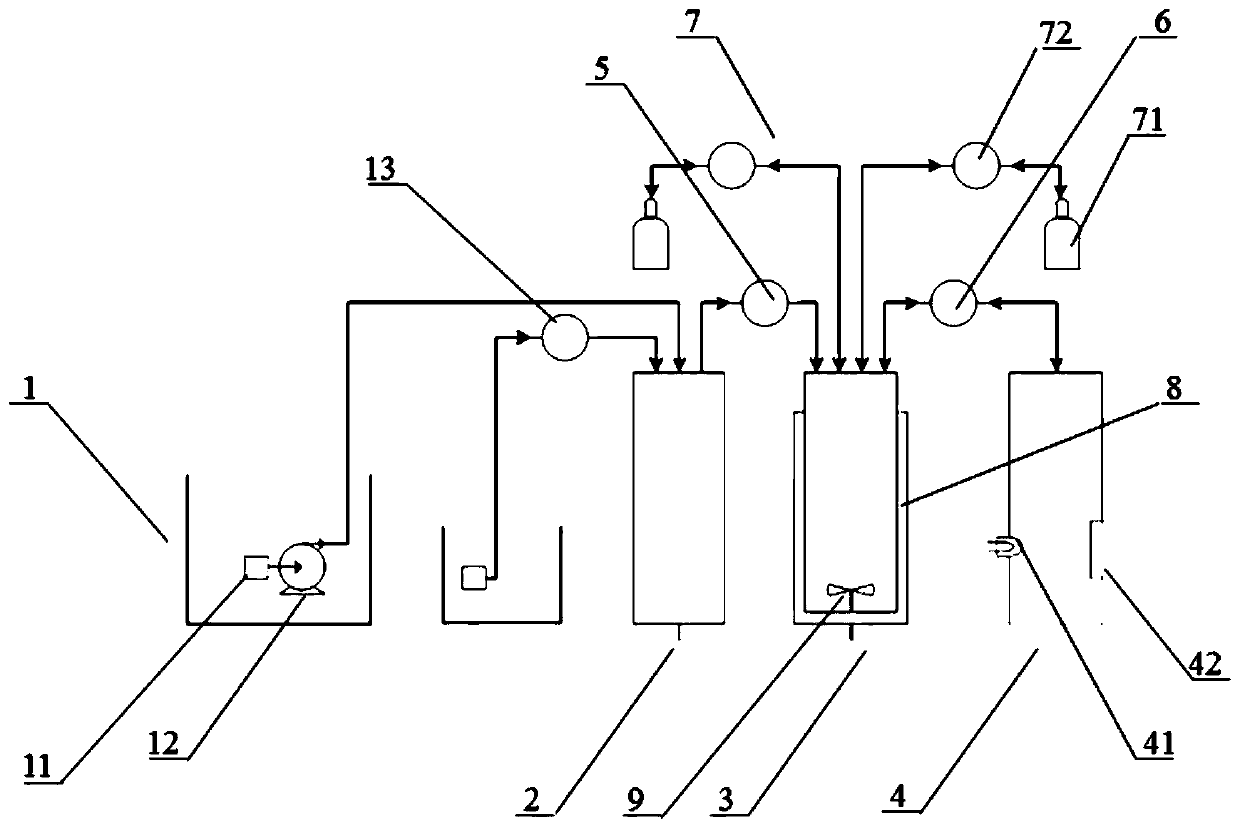

[0032] An automatic detection device for the content of ammonia nitrogen and nitrite, which includes a sampling component 1, a buffer component 2, a reaction component 3 and an observation component 4 which are connected in sequence; the sampling component 1 is connected to the buffer component 2 by two parallel branches One branch is composed of the connected pre-filter 11 and the submersible pump 12. The outlet of the submersible pump 12 is connected to the inlet of the buffer component 2, and the other branch is composed of the connected pre-filter 11 and the second The outlet of the second peristaltic pump 13 is connected to the inlet of the buffering part 2; the outlet of the buffering part 2 and the inlet of the reaction part 3 are provided with a first peristaltic pump 5; the outlet of the reaction part 3 and the observation part 4 A two-way peristaltic pump 6 is provided between the inlets; the inlet of the reaction part 3 is also connected to two reagent parts 7, the re...

Embodiment 2

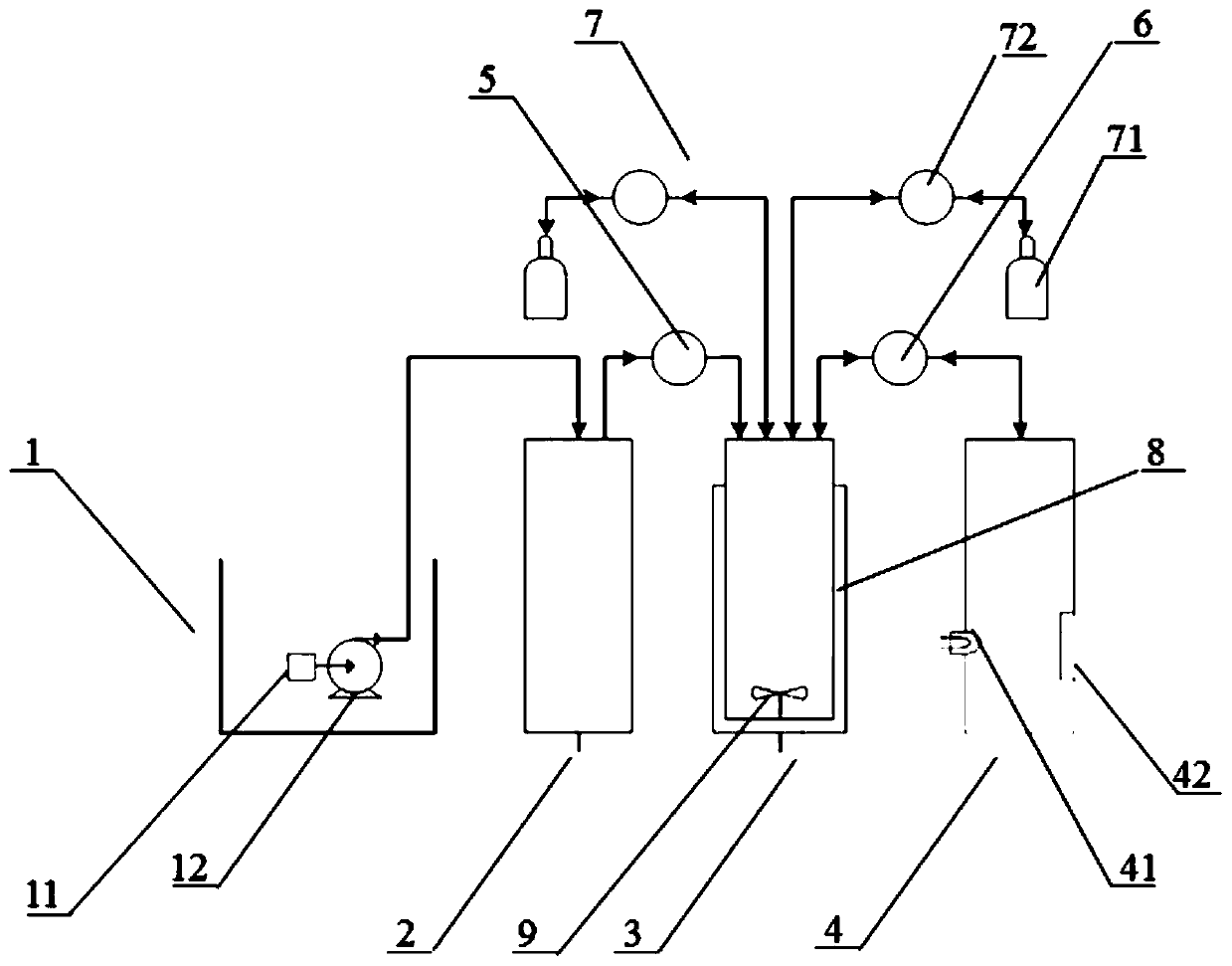

[0047] An automatic detection device for the content of ammonia nitrogen and nitrite, comprising a sampling component 1, a buffer component 2, a reaction component 3 and an observation component 4 which are connected in sequence; the sampling component 1 is connected by a pre-filter 11 and a submersible pump 12, the outlet of the submersible pump 12 is connected to the inlet of the buffer component 2; the first peristaltic pump 5 is provided between the outlet of the buffer component 2 and the inlet of the reaction component 3; the outlet of the reaction component 3 and the inlet of the observation component 4 are provided There is a two-way peristaltic pump 6; the inlet of the reaction part 3 is also connected to two reagent parts 7. The reagent part 7 is composed of a connected reagent bottle 71 and a reagent pump 72. The outlet of the reagent pump 72 is connected to the inlet of the reaction part 3. The pump 72 is bidirectionally rotating; the outside of the reaction part 3 i...

Embodiment 3

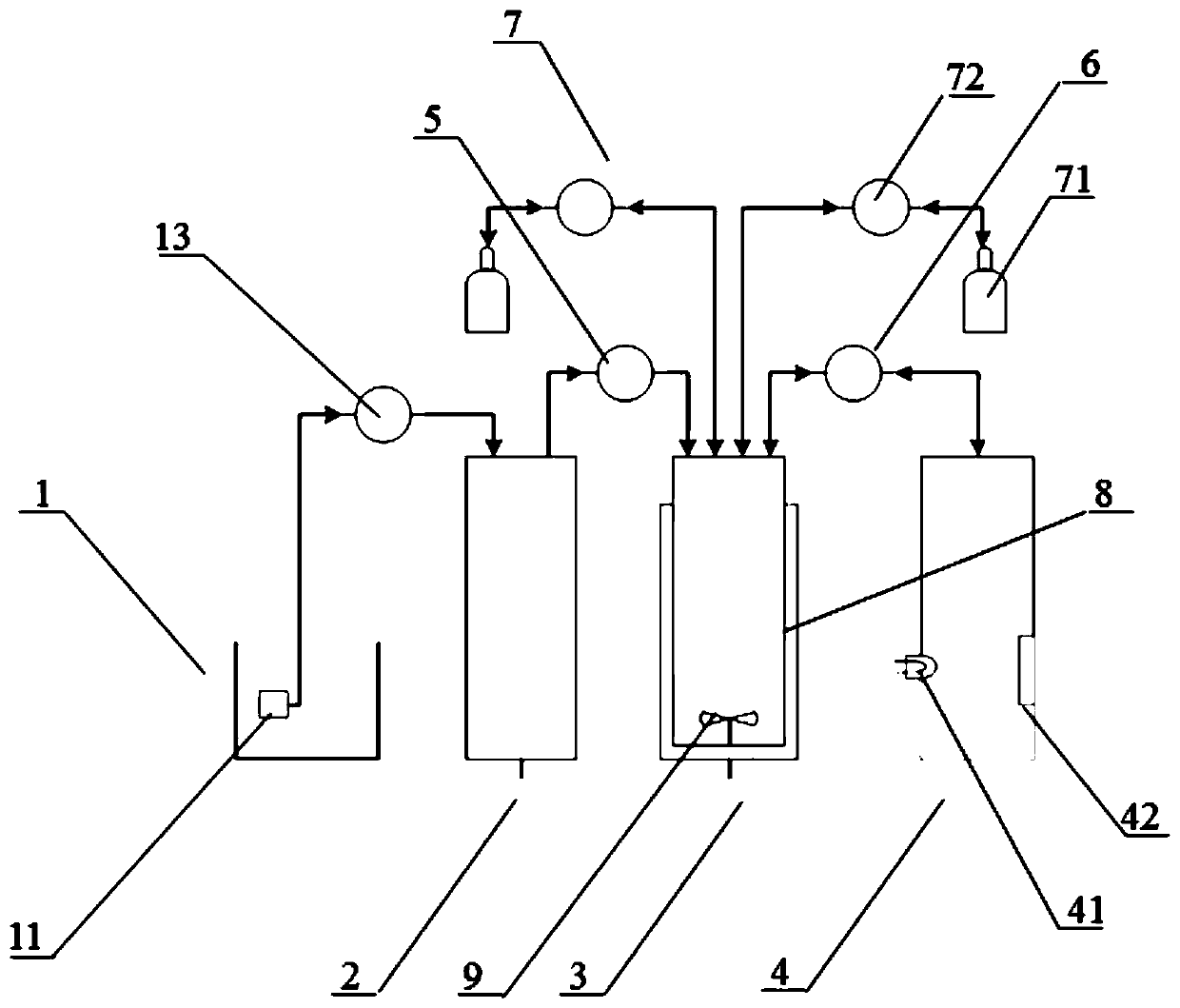

[0061] An automatic detection device for the content of ammonia nitrogen and nitrite, which includes a sampling component 1, a buffer component 2, a reaction component 3, and an observation component 4 that are connected in sequence; the sampling component 1 is connected by a pre-filter 11 and a second The outlet of the second peristaltic pump 13 is connected to the inlet of the buffering part 2; the outlet of the buffering part 2 and the inlet of the reaction part 3 are provided with a first peristaltic pump 5; the outlet of the reaction part 3 and the observation part 4 A two-way peristaltic pump 6 is provided between the inlets; the inlet of the reaction part 3 is also connected to two reagent parts 7, the reagent part 7 is composed of a connected reagent bottle 71 and a reagent pump 72, and the outlet of the reagent pump 72 is connected to the reaction part 3. The reagent pump 72 rotates bidirectionally at the entrance of the reaction part 3; the outside of the reaction part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com