Coal-pillar-free mining method for pre-cracking arching under hard roof condition

A technology of hard roof and mining method, used in underground mining, surface mining, underground chambers, etc., can solve the problems of easy air leakage and broken roadway roof, and achieve the effect of reducing risk, reducing roadway deformation and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

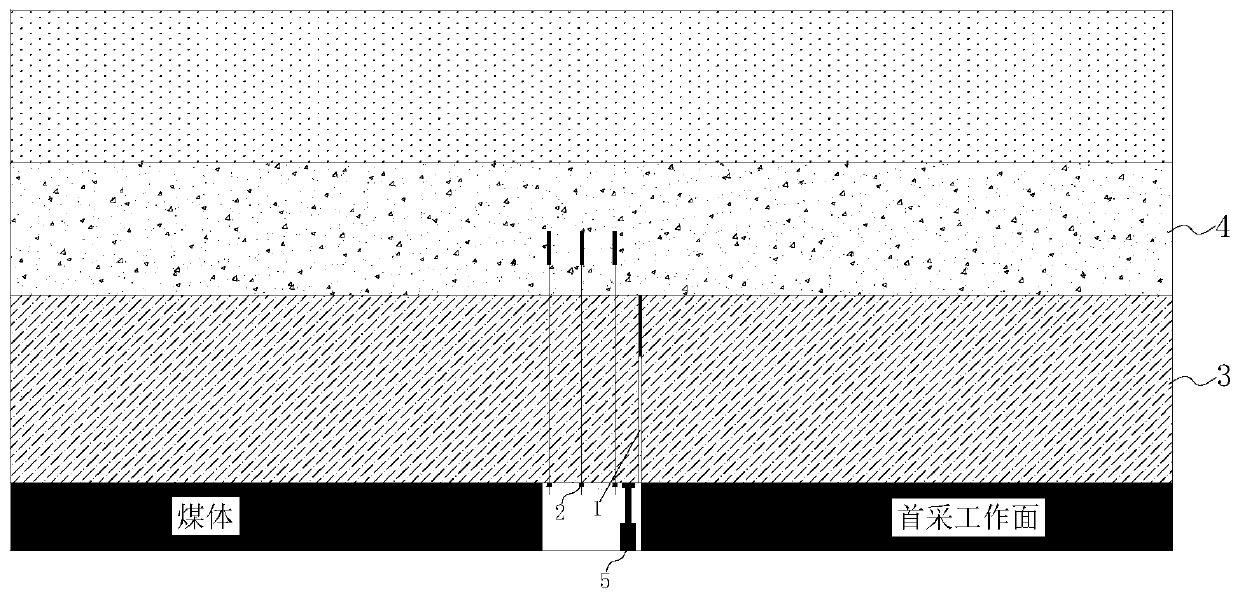

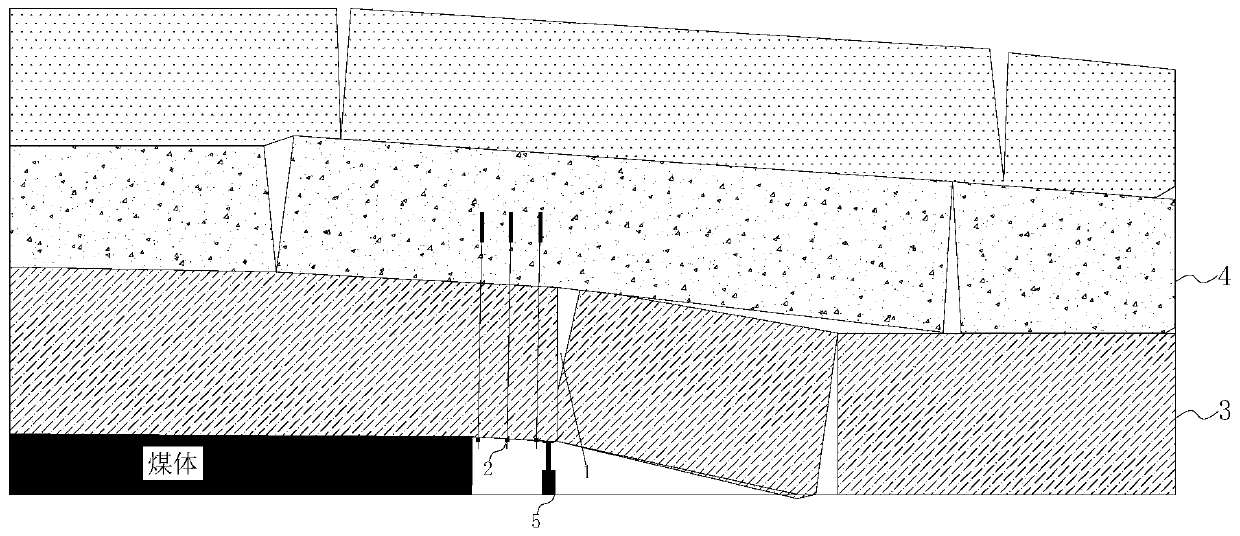

[0033] In order to adapt to the coal pillarless mining under the hard roof condition, a coal pillarless mining method of pre-splitting and arching under the hard roof condition is proposed. After the working face is advanced, the upper part of the direct roof is cracked. Due to the connection of the lower part, the direct roof bends and sinks into an arch. The roadway is deformed, and due to the small blasting range of the pre-splitting holes, a relatively complete roof is maintained, which can effectively prevent air leakage from the roof. The specific construction steps of the method include:

[0034] Step A. Excavate the recovery roadway at the first mining face, and use bolts and anchor cables to support the recovery roadway.

[0035] The roof of the mining roadway in the first mining face is supported by anchor cables + steel belts + anchor nets. The steel belt can be M steel belt, and the number of anchor cables is set according to the formula Calculate, where n is th...

Embodiment 2

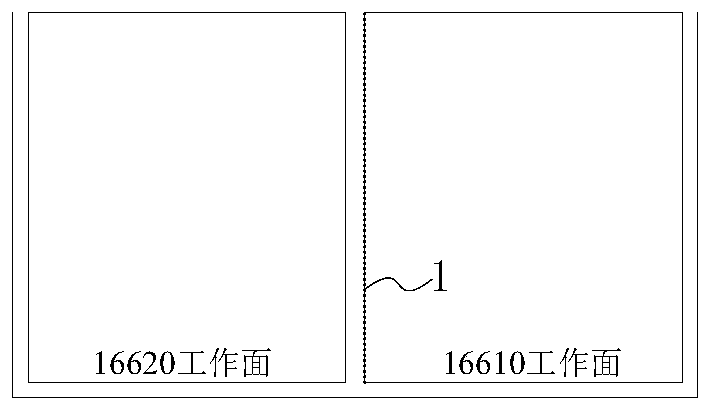

[0051] On the basis of Example 1, taking the mining of the 16# coal seam in a certain mine as an example, the coal pillar-free mining method of pre-splitting and arching under the condition of a hard roof is further described in detail.

[0052] The 16# coal seam of a certain mine is relatively stable, with a strike length of 741.1m, located in the lower part of the Taiyuan Formation, under ten lower limestones, with an average thickness of 0.86m; the columnar diagram of the coal seam is as follows Figure 5 shown. The strike of the coal strata is 30°-40° northwest, and the inclination is generally around 3°-8°; the relative emission of mine gas is 0.79m 3 / t, for low gas mine; CO 2 The relative gushing volume is 1.38m 3 / t; the coal dust explosion index is 44.54%, which has the danger of coal dust explosion; the shortest spontaneous combustion period of coal is 94 days; the spontaneous combustion tendency of coal seam is class II spontaneous combustion coal seam. The direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com