Pile foundation structure reinforced by single-pile foundation of offshore wind turbine generator set and construction method

A single-pile foundation and offshore wind power technology, which is applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as increased load of wind turbines, excessive verticality error of pile sinking, difficulty in sinking piles in place, etc., to achieve reduction The effect of investment cost, simple structure design and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

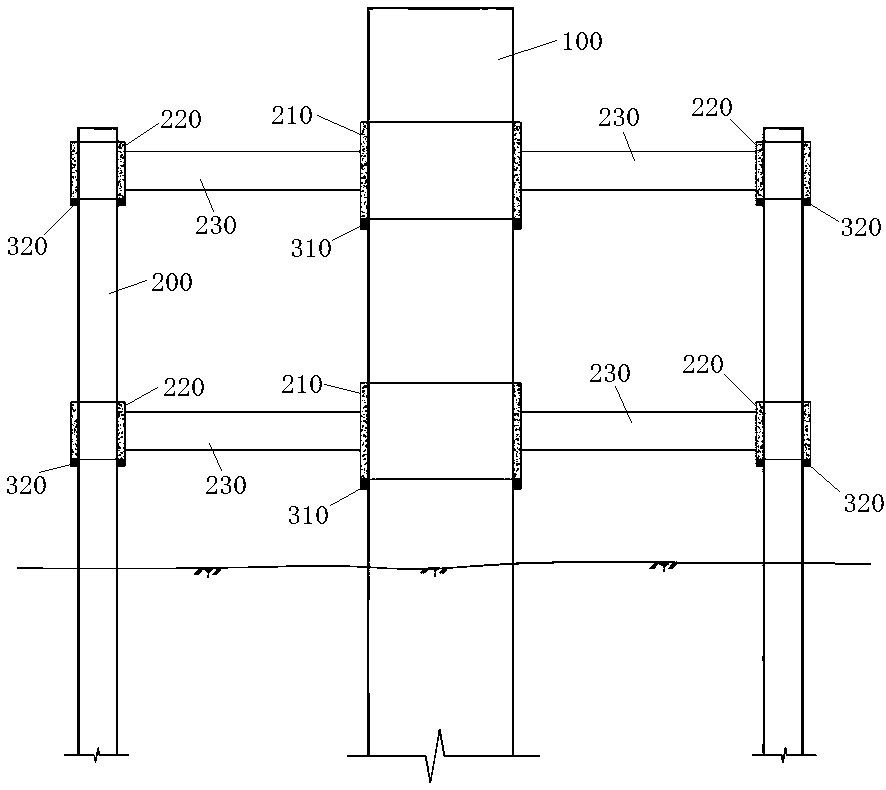

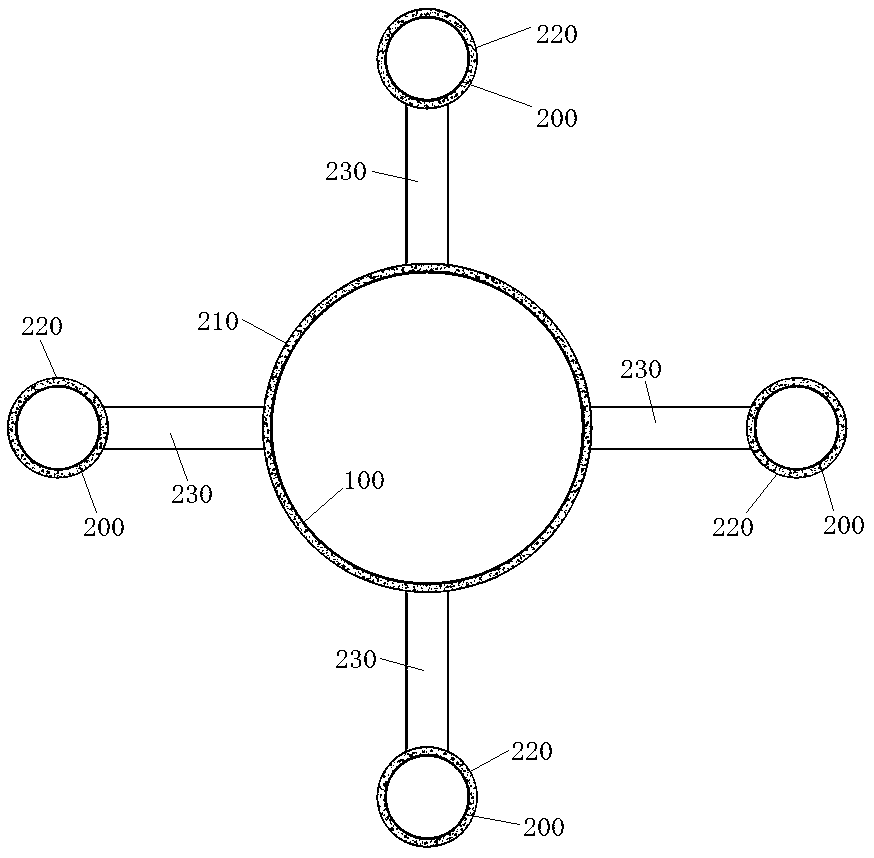

[0039] Embodiment one: if Figure 1~2 As shown, the present invention provides a single-pile foundation reinforcement structure for offshore wind turbines, including a vertically arranged single-pile foundation 100 for offshore wind turbines, and four steel pipes that are uniformly distributed around the single-pile foundation 100 Pile 200, the four steel pipe piles are all parallel to the single pile foundation, the diameter of the steel pipe pile 200 is smaller than the diameter of the single pile foundation 100 and sinks into the seabed body, the four steel pipe piles 200 and the single pile foundation 100 There are two layers of composite beam structure at intervals from top to bottom. The composite beam structure includes a central sleeve 210 fixedly sleeved on the outside of the single pile foundation 100. The outside of the central sleeve 210 is provided with four A skirt pile sleeve 220 uniformly distributed on the circumference and corresponding to the position of the...

Embodiment 2

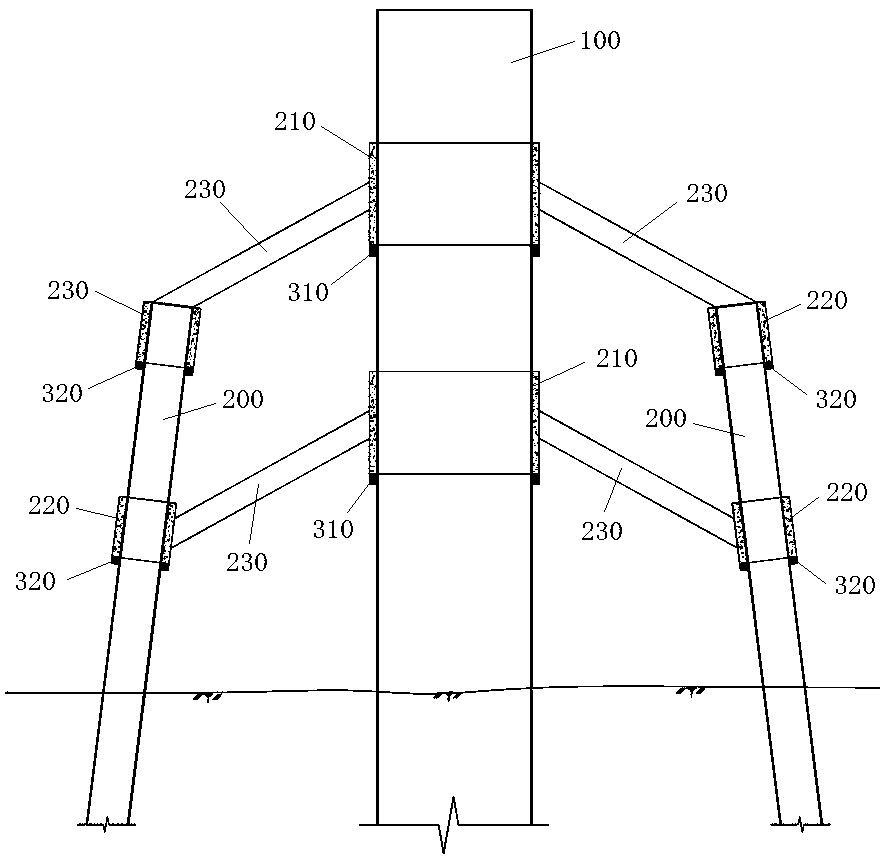

[0045] Embodiment two: if Figure 3-4 As shown, the difference between the present embodiment and the first embodiment is that at least three steel pipe piles are radially distributed, and each steel pipe pile is arranged obliquely to the single pile foundation. It should be noted that the angle between the steel pipe pile and the single pile foundation can be set or adjusted according to actual needs.

[0046] Through the research and development of the single pile foundation of offshore wind turbines to strengthen the pile foundation structure, the reliable connection between multiple steel pipe piles and composite beam structures and the single pile foundation of offshore wind turbines can effectively improve the compression resistance, pullout resistance and horizontal bearing capacity of the single pile foundation Force, horizontal height, overall structural stability, short offshore construction time, and easy control of construction accuracy, not only can efficiently an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com