Method for manufacturing a PHC tubular pile in soft soil region through chambering and grouting

A technology of PHC pipe piles and grouting pipes, applied in soil protection, sheet pile walls, construction, etc., can solve problems such as difficulty in obtaining social and economic benefits, complicated construction procedures, and low construction efficiency, so as to improve social and economic benefits and improve Anti-seepage effect, improve the effect of compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

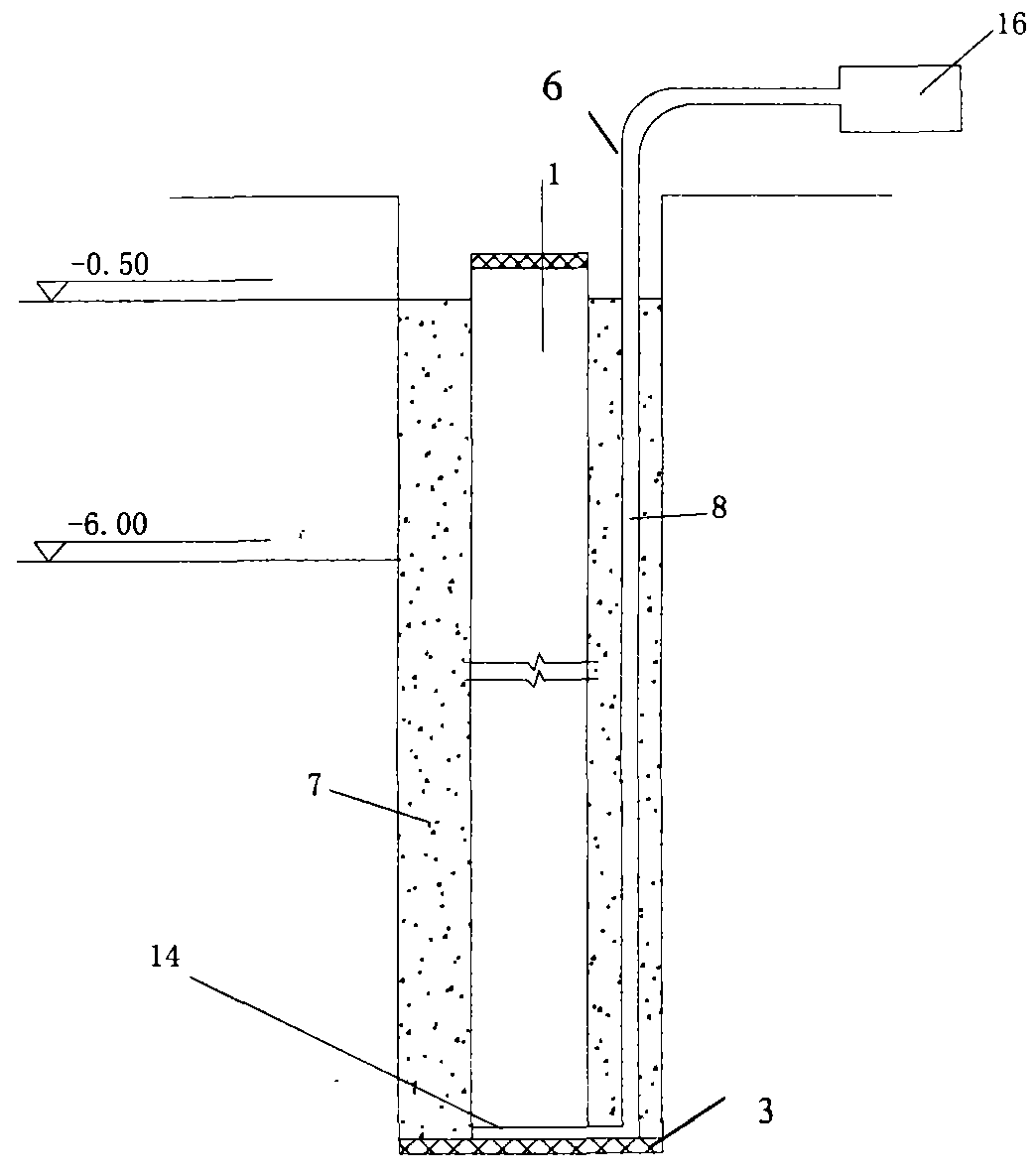

[0025] The method for making the reaming and grouting PHC pipe piles in soft soil areas of the present invention will be described in conjunction with the accompanying drawings and embodiments.

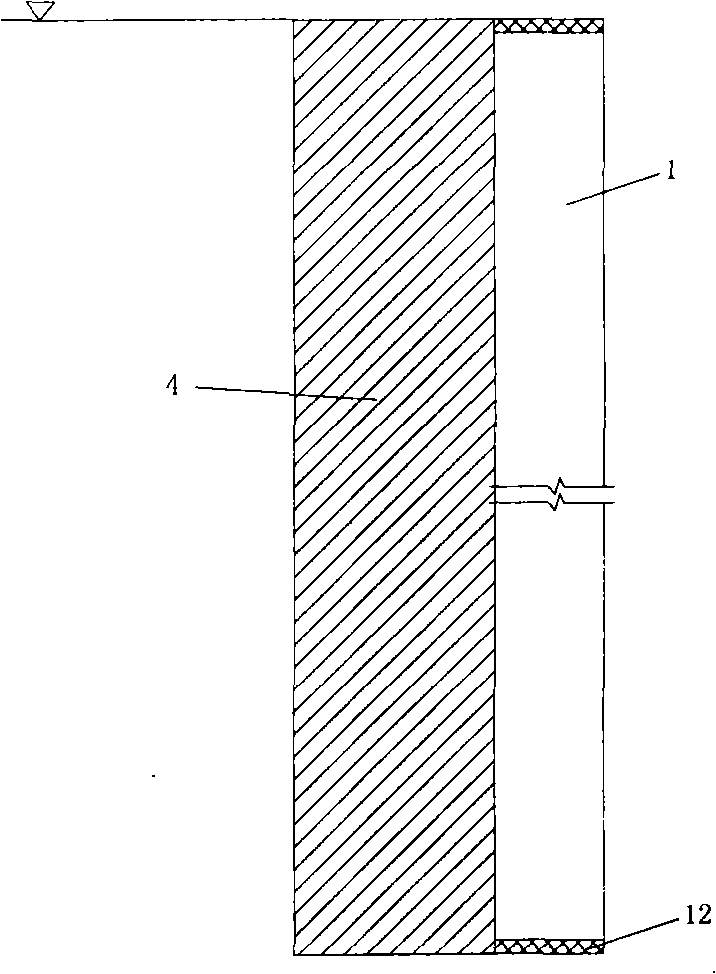

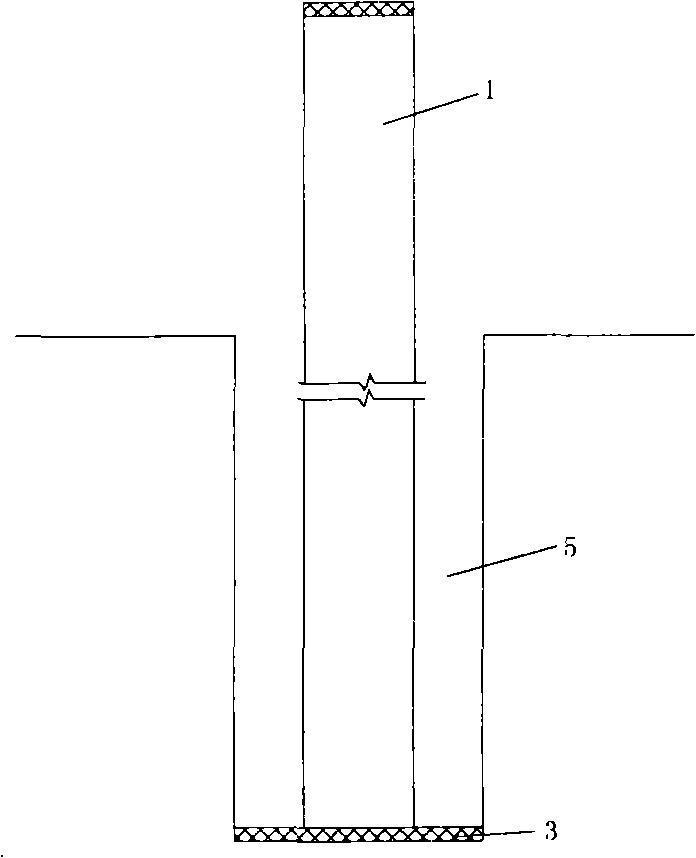

[0026] The pile end of the sinking PHC pipe pile 1 adopts the enlarged head plate 3, the area of the enlarged head plate 3 is larger than the cross-sectional area of the PHC pipe pile, and the steel plate larger than the cross-sectional area of the PHC pipe pile is used to connect to the bottom pile of the HC pipe pile 1 end, as shown in Figure 2.

[0027] The shape of the enlarged head plate 3 can have various shapes such as square, circular, triangular or elliptical according to the difference in the nature of the formation, and the area of the expanded head plate 3 can be 1.5-3 times of the cross-sectional area of the PHC pipe pile 1. The enlarged head plate 3 can adopt two forms of enlarging the area of the end plate 12 or directly welding a steel plate greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com