Composite modified sesame protein adhesive, and preparation method thereof

A technology of composite modification and protein glue, which is applied in the field of composite modified sesame protein adhesive and its preparation, can solve the problems of low bonding strength and poor water resistance of vegetable protein adhesives, achieve high bonding strength and increase additional output value , good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of composite modified sesame protein adhesive, comprising the following steps:

[0021] (1) carrying out the first stirring treatment with the sesame protein and the urea solution, to obtain the stirred liquid;

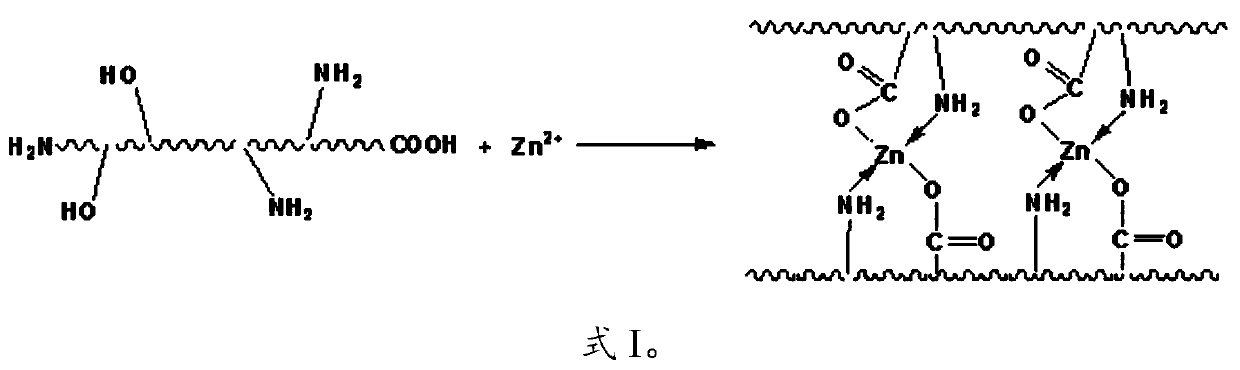

[0022] (2) The stirring solution and the metal oxide are subjected to a second stirring treatment to obtain a composite modified sesame protein adhesive; the mass of the metal oxide is 4% to 12% of the sesame protein mass.

[0023] In the present invention, the sesame protein and urea solution are subjected to the first stirring treatment to obtain the stirred liquid. In the present invention, the sesame protein is extracted from sesame cake, which is a by-product of a sesame oil processing enterprise. The present invention has no special requirements on the source of the sesame protein. Commercially available sesame protein or self-prepared can be. The invention uses the sesame protein to prepare the vegeta...

Embodiment 1

[0032] Weigh 10g of sesame protein, add it to 80mL 3mol / L urea solution, stir at 25°C for 20min, add a small amount of tributyl phosphate while stirring, then add zinc oxide, the amount of zinc oxide added is the amount of sesame protein 8% (ie 0.8g) of urea-zinc oxide composite modified sesame protein adhesive was obtained under the condition of 25° C. for 3 hours, and the solid content of the adhesive was 28.2%.

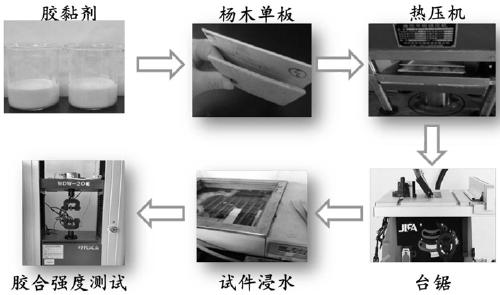

[0033] The prepared urea-zinc oxide composite modified sesame protein adhesive was used to prepare plywood, and the water resistance of plywood was reflected by measuring the wet bonding strength of plywood. Specific steps are as follows:

[0034] Prepare two poplar veneers, and evenly coat the compound modified adhesive on the surface of one poplar veneer, the coating amount is 240g / cm 2 , and then two pieces of poplar veneers are hot-pressed and bonded to obtain a plywood. The hot-pressing temperature is 140° C. and the pressure is 1.2 MPa. Saw the plywood in a...

Embodiment 2

[0037] Other conditions are the same as in Example 1, only the addition of zinc oxide is replaced by 4% (i.e. 0.4g) of the addition of sesame protein to obtain the urea-zinc oxide composite modified sesame protein adhesive, the solid content of the adhesive was 28.2%.

[0038] The plywood was prepared according to the method of Example 1 and the wet bonding strength of the plywood was tested. The results showed that the wet bonding strength of the plywood was 1.01MPa, which was greater than the national requirement for Class II plywood (0.7MPa).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com