Multifunctional wheatgrass paint, preparation method thereof and wall construction method of paint

A multi-functional and multi-functional additive technology, which is applied in paints, coatings, constructions, etc. containing biocide, can solve the problem of relatively little improvement of coatings, achieve good storage stability, simple construction, and long color retention time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

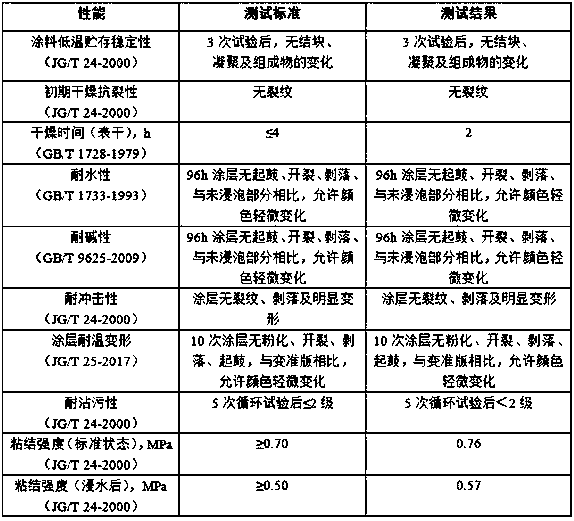

Examples

Embodiment 1

[0035] The multifunctional wheat straw paint of present embodiment 1, the described wheat straw paint of every ton adopts the component allocation of following Kg number to form:

[0036] 140Kg of water, 1Kg of hydroxyethyl cellulose, 5 Kg of alcohol ester dodecane, 4Kg of propylene glycol, 1.2Kg of NipacideDF / 1, 1 Kg of AMP-95, 1 Kg of NSS22, 1 Kg of polyurethane rheology modifier, 120Kg of RS silicone acrylic emulsion , marble powder 2 Kg, leveling agent 2 Kg, ethylene glycol monobutyl ether 1.5 Kg, nano-calcium carbonate 430 Kg, silicon bath soil 50 Kg, nano-zinc oxide 15kg, vermiculite powder 15kg, shell powder 20Kg, rutile titanium dioxide 2 Kg, natural round sand 250 Kg, anti-mildew special wheat straw 3 Kg, color paste 5Kg;

[0037] In the preparation method of the above-mentioned multifunctional wheat straw varnish, its components are added according to the formula, which specifically includes the following steps:

[0038] (1) Preparation of enzyme-resistant special w...

Embodiment 2

[0052] The multifunctional wheat straw paint of present embodiment 2, the described wheat straw paint of every ton adopts the component allocation of following Kg number to form:

[0053] Water 100Kg, hydroxyethyl cellulose 2Kg, alcohol ester dodecane 5 Kg, propylene glycol 6Kg, NipacideDF / 1 1Kg, AMP-95 1.5 Kg, NSS22 1.5Kg, polyurethane rheology modifier 2 Kg, RS silicone acrylic emulsion 90Kg, Marble powder 1 Kg, leveling agent 1Kg, nano-calcium carbonate 300 Kg, silicon bath soil 30 Kg, nano-zinc oxide 18kg, vermiculite powder 18kg, shell powder 15Kg, rutile titanium dioxide 1 Kg, natural round sand 200 Kg, anti-mildew Special wheat straw 1 Kg, color paste 6kg;

[0054] In the preparation method of the above-mentioned multifunctional wheat straw varnish, its components are added according to the formula, which specifically includes the following steps:

[0055] (1) Preparation of enzyme-resistant special wheat straw: Spread non-mildew wheat straw on a clean ground, repeated...

Embodiment 3

[0060] The multifunctional wheat straw paint of present embodiment 3, the described wheat straw paint of every ton adopts the component allocation of following Kg number to form:

[0061] Water 150Kg, hydroxyethyl cellulose 3Kg, alcohol ester dodecane 5 Kg, propylene glycol 8Kg, NipacideDF / 1 3Kg, AMP-952Kg, NSS22 2Kg, polyurethane rheology modifier 3Kg, RS silicone acrylic emulsion 140Kg, marble powder 4 Kg , leveling agent 3Kg, ethylene glycol monobutyl ether 3Kg, nano-calcium carbonate 500 Kg, silicon bath soil 80 Kg, nano-zinc oxide 20kg, vermiculite powder 20kg, shell powder 30Kg, rutile titanium dioxide 6Kg, natural round sand 300 Kg, Anti-mildew special wheat straw 8Kg, color paste 8Kg;

[0062] In the preparation method of the above-mentioned multifunctional wheat straw varnish, its components are added according to the formula, which specifically includes the following steps:

[0063] (1) Preparation of special enzyme-resistant wheat straw: spread non-mildew wheat str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com