Resin composition applicable to laser welding and with high metal texture and preparation method thereof

A resin composition and laser welding technology, which is applied in the field of car lights, can solve problems such as low laser absorption rate and two parts cannot be welded to welding strength, etc., achieve simple process operation, improve laser absorption rate and welding strength, and improve Effect of Welding Strength and Welding Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] A laser-weldable resin composition with high metallic texture is used for injection molding the resin composition into a car lamp bezel, and laser welding is performed on the car lamp bezel and a transparent PC inner light distribution mirror.

[0105] The resin composition preparation method comprises the following steps:

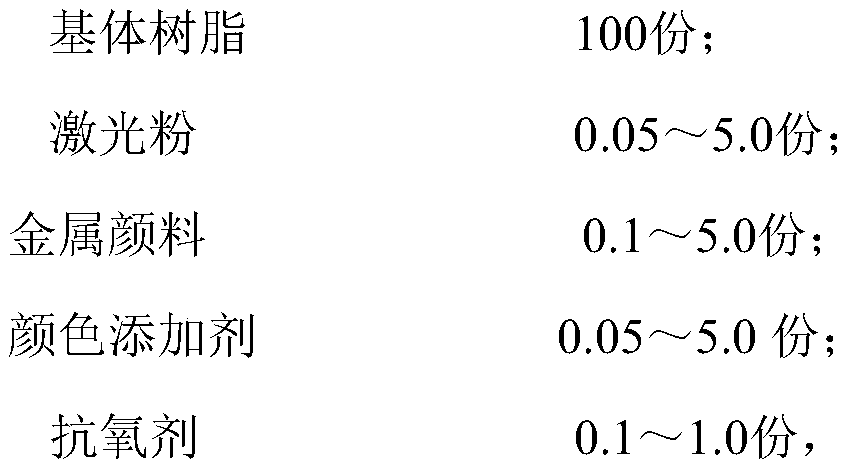

[0106] Prepare raw materials according to the following components and parts by weight:

[0107]

[0108] The laser powder is Sn / In mixed oxide type,

[0109] The metal pigment is aluminum powder with a particle diameter of 0.5 μm to 40 μm.

[0110] The color additive is selected from inorganic toner with a particle size of 0.001 μm to 1 μm rutile titanium dioxide and iron oxide red iron oxide, and pearlescent powder with a particle size of 0.001 μm to 50 μm. The core of the pearlescent powder is mica with a low optical refractive index. The outer layer is coated with titanium dioxide or iron oxide with a high refractive index, and ceramic powd...

Embodiment 2

[0116] A laser-weldable resin composition with high metallic texture is injection-molded into a flat plate, which is laser-welded with a transparent PC plate and used for molding to obtain car lamp parts. Or the resin composition is injection-molded into a car lamp bezel, and the car light bezel is directly laser-welded with a transparent PC inner light distribution mirror. Its preparation method comprises the following steps:

[0117] Prepare raw materials according to the following components and parts by weight:

[0118]

[0119]

[0120]The laser powder is selected from Sn / Sb mixed oxide type (50%)+TiO2 type (50%),

[0121] The metal pigment is zinc powder (50%)+copper powder (50%) with a particle size of 0.5 μm to 40 μm,

[0122] The color additive is selected from carbon black series + iron oxide series + chromium series and metal oxide mixed-phase pigment system with inorganic toner particle size of 0.001 μm ~ 1 μm, pearl powder with particle size of 0.001 μm ~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com