MQ resin based organic silicon surfactant and preparation method thereof

A technology of surfactant and silicone, which is applied in the field of silicone resin or silicone surfactant to achieve long-term stability, high-efficiency emulsification, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Utilize the inventive method to prepare hydrogen-containing MQ resin, (HR 2 SiO 1 / 2 ) m+n (R 3 SiO 1 / 2 ) p (SiO 2 ) q : Add 0.013 mol (1.75 g) of tetramethyldisiloxane (TMDS), 0.107 mol (17.4 g) of hexamethyldisiloxane into a 250 mL three-neck flask equipped with a reflux condenser, mechanical stirring and ice-water bath Oxygen (HMDS), 24.0 g deionized water, 12.0 g absolute ethanol, 16.0 g concentrated hydrochloric acid, vigorously stir and mix until transparent, add 0.4 mol (83.3 g) orthoethyl silicate (TEOS) with a constant liquid funnel, Control the dropping time to 1 h. After the ethyl orthosilicate was added, the stirring reaction was continued at room temperature for 1 h. After standing for stratification, pour off the upper liquid, wash the lower organic layer with water to neutrality, and then raise the temperature to 120 o C, Residual solvents and low molecular compounds were removed under 100 Pa vacuum conditions to obtain a colorless and transparent...

Embodiment 2~10

[0044] According to the exact same method as in Example 1, the hydrogen-containing MQ resins in Examples 2 to 10 were prepared by using different raw material combinations as shown in Table 1, and the hydrogen-containing MQ resins in Examples 2 to 10 were measured by gel permeation chromatography (GPC) at the same time. Weight-average molecular weight M of hydrogen-containing MQ resin w and molecular weight distribution M w / M n (See Table 1).

[0045] Table 1

[0046]

[0047] By comparing Examples 1 to 10 of the present invention, it is found that the obtained hydrogen-containing MQ resin can be regulated by controlling the molar ratio of tetramethyldisiloxane and hexamethyldisiloxane to the capping agent (tetramethyldisiloxane and hexamethyldisiloxane). In other words, the size of the MQ resin can be regulated. The higher the molar ratio, the larger the molecular weight and size of the obtained MQ resin. It is found that the molecular weight distribution of the MQ re...

Embodiment 11

[0049] Hydrosilylation reaction is used to graft hydrophilic / hydrophobic groups on the surface of hydrogen-containing MQ resins to prepare silicone surfactants based on MQ resins, (F 1 R 2 SiO 1 / 2 ) m (F 2 R 2 SiO 1 / 2 ) n (R 3 SiO 1 / 2 ) p (SiO 2 ) q : Add 2.0 g of hydrogen-containing MQ resin obtained in Example 1 to a 100 mL two-necked flask equipped with a reflux condenser, magnetic stirrer and rubber stopper, vent nitrogen, then vacuumize, and repeat three times to make the bottle full of nitrogen. Inject 50 mL of anhydrous toluene, 0.1 mL of xylene solution containing platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane catalyst, 0.011 mol (2.78 g) octadecene (C 18 h 36 ), 0.003 mol (1.49 g) polyethylene glycol monoallyl ether (HPAE, molecular weight 498), mix well. Heat to 120 o C was reacted for 12 h, and then low-molecular compounds were removed under 100 Pa vacuum condition to obtain a light yellow silicone surfactant based on MQ resin.

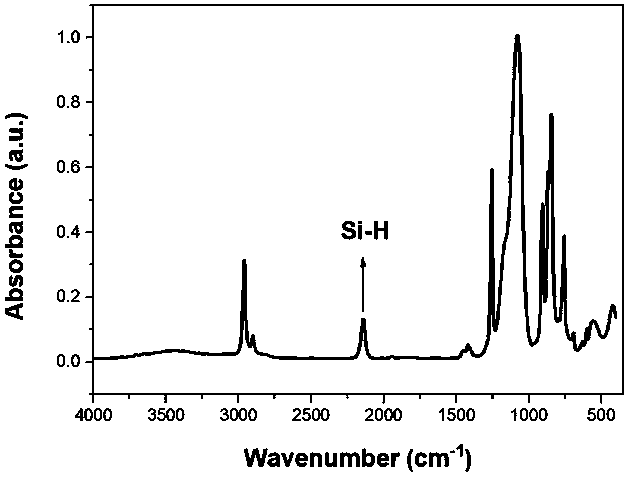

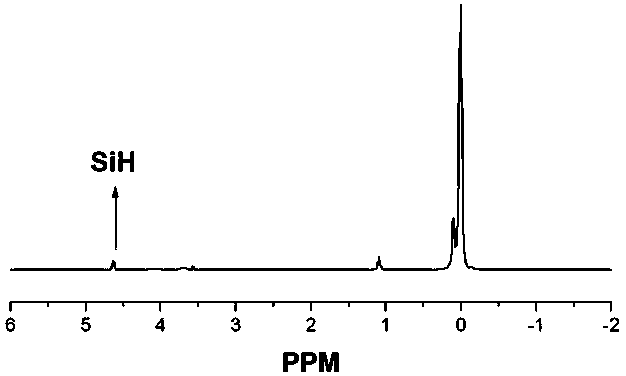

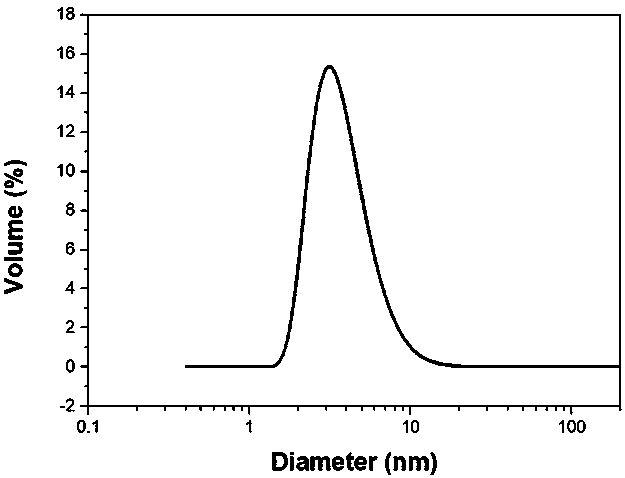

[0050] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| hydrodynamic diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com