Cold-mixed and cold-laid anion emulsified asphalt and preparation method and application thereof

An emulsified asphalt and anion technology, applied in the field of building materials, can solve the problems of insufficient bonding, asphalt peeling, unable to exert the properties of emulsified asphalt, etc., and achieve the effect of reducing pollution and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

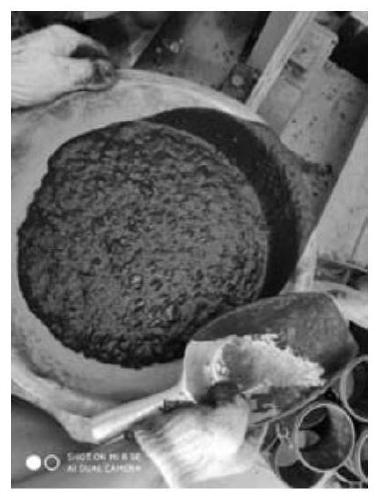

Image

Examples

Embodiment 1

[0058] The examples given are for better description of the content of the present invention, but the content of the present invention is not limited to the examples given. Therefore, non-essential improvements and adjustments to the implementation by those skilled in the art based on the content of the invention above still fall within the protection scope of the present invention.

[0059] A cold-mixed cold-paved anionic emulsified asphalt and a preparation method thereof, comprising the steps of:

[0060] Step 1: Prepare the emulsifier and water according to a certain ratio, stir well, adjust the pH to 11-13, and add an appropriate amount of stabilizer. The emulsifier used is A3T1 anionic slow-cracking emulsifier with a dosage of 3.5%. The dosage of stabilizer is 0.1%;

[0061] Step 2: Heat the prepared emulsion to 60°C, and at the same time start the shearing instrument for shearing, the speed of the shearing instrument is controlled at 2000r / min, and the shearing time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com