Method for extracting sodium thiocyanate, sodium thiosulfate and sodium sulfate from desulphurization waste liquid of oven gasalkali process

A technology of sodium thiosulfate and desulfurization waste liquid, which is applied in the direction of thiosulfate/dithionite/polythionate, alkali metal sulfite/sulfate purification, thiocyanate, etc., and can solve the problem of equipment Corrosion, increasing the load of the gas purification system, reducing the service life and other problems, achieving good economic benefits and realizing the effect of resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

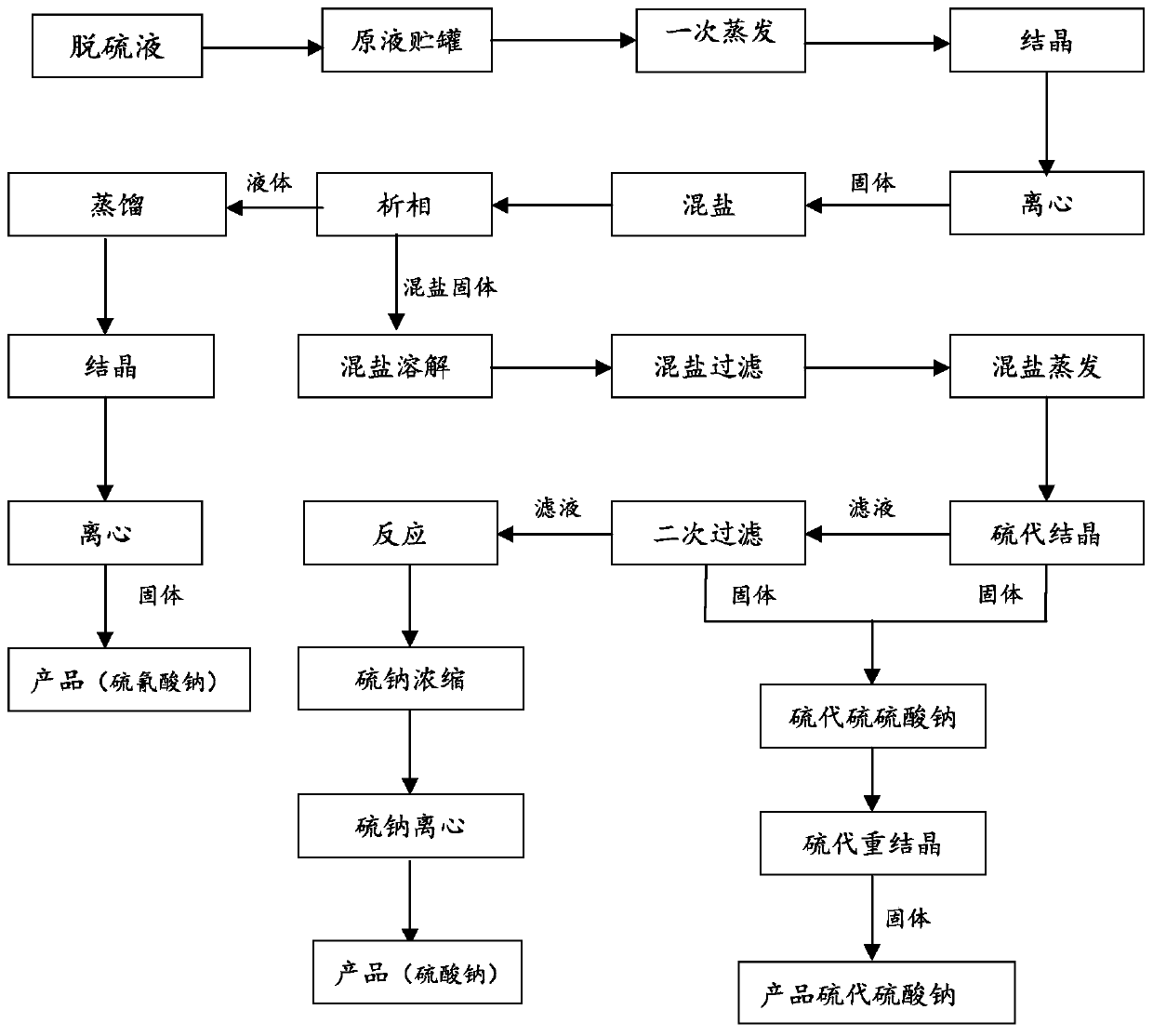

Image

Examples

Embodiment 1

[0033] A method for extracting sodium thiocyanate, sodium thiosulfate and sodium sulfate from coke oven gas-alkali desulfurization waste liquid. The mixed salt obtained by evaporating and concentrating the desulfurization waste liquid is extracted with an organic solvent to obtain sodium thiocyanate product. During the process, the whole process of nitrogen protection is adopted, and nitrogen is filled from the air inlet of the centrifuge for protection. Sodium thiocyanate is extracted with an organic solvent. The organic solvent is easy to catch fire and explode, and the extracted sodium thiocyanate has a high temperature environment during the centrifugation process. , It is easy to catch fire and explode, so it is protected by nitrogen; the mixed salt of sodium thiosulfate and sodium sulfate is separated by fractional crystallization to obtain sodium thiosulfate products and sodium sulfate products. Include the following steps:

[0034] (1) One-time evaporation: decolorize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com