Sulfur recovery device and method based on automatic adjustment of Claus air distribution

A sulfur recovery and automatic adjustment technology, which is applied in the direction of sulfur preparation/purification, energy input, etc., can solve the problems of auxiliary wind losing its regulating effect and the influence of sulfur recovery device operation, and achieve the effect of avoiding airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

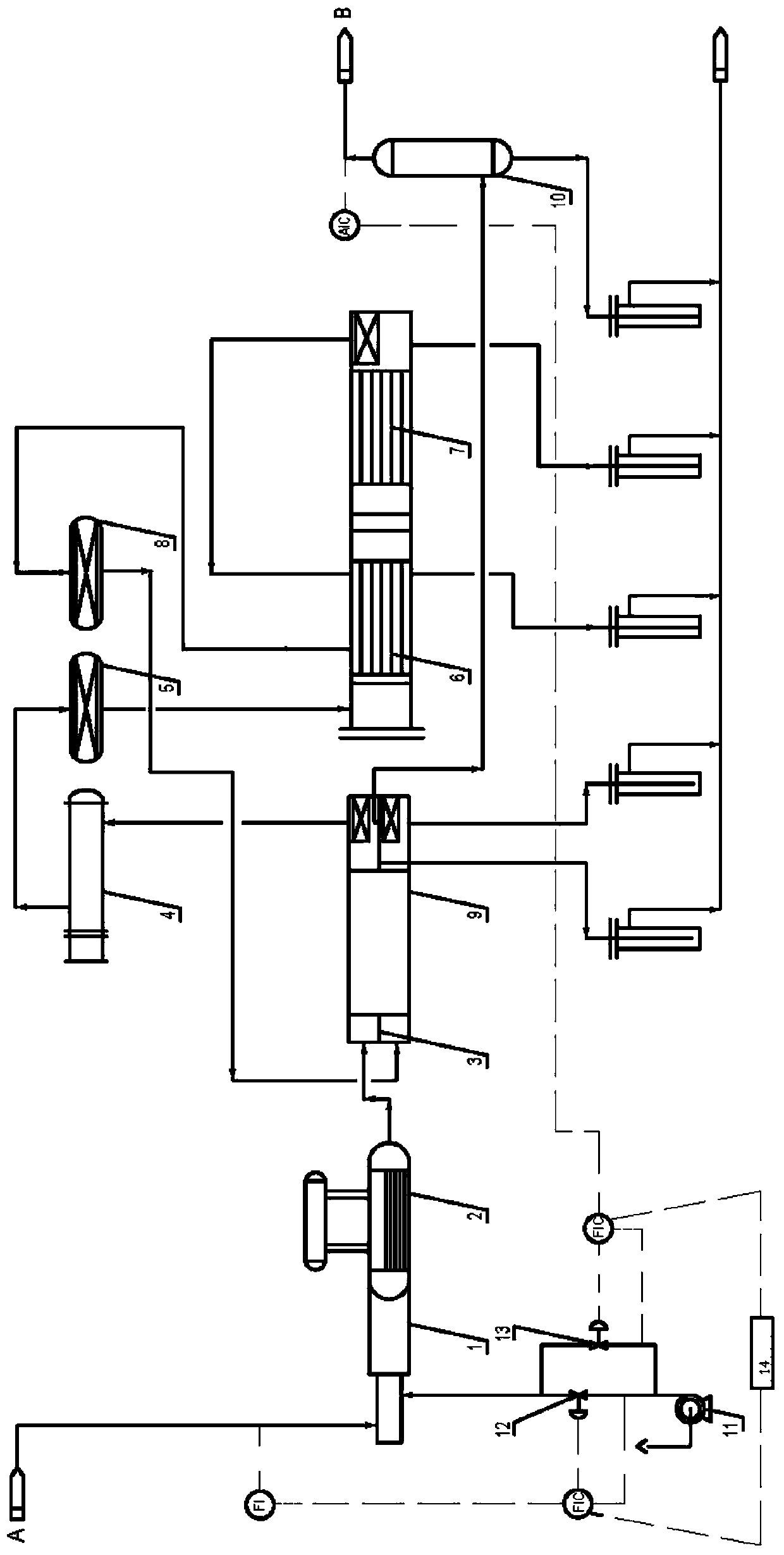

Method used

Image

Examples

Embodiment 1

[0096] In this example, the high-temperature process gas in the waste heat boiler for sulfur production is cooled to 320°C, the process gas in the primary condensing cooler is cooled to 160°C, the temperature of the process gas in the steam heater is raised to 240°C, and the process gas in the process gas heat exchanger is cooled to 275°C, the process gas in the secondary condensing cooler is cooled to 160°C, the process gas in the process gas heat exchanger is heated to 220°C, and the process gas in the third condensing cooler is cooled to 160°C.

[0097] Initial acid gas H 2 S concentration 85%, initial acid gas flow 1060Nm 3 / h, based on H 2 S chemical reaction equation to calculate the main wind proportional coefficient K 0 is 2, the initial set value is calculated according to formula Ⅰ: the main air flow is 2120Nm 3 / h, range is 3000Nm 3 / h; auxiliary air flow is 100Nm 3 / h, range is 500Nm 3 / h.

[0098] After the Claus reaction, H 2 S / SO 2 Online detection inst...

Embodiment 2

[0105] The difference from Example 1 is that when the acid gas flow rate is constant but the concentration changes, the H 2 S / SO 2 Significant changes in the test results of online testing instruments, SO 2 Concentration 0.6% (mol%), H 2 The concentration of S is 0.2% (mol%); the control module calculates the change of the secondary air according to the formulas I, II, and III, and the flow of the main air is kept at 2120Nm 3 / h,Q 副风原设定值 100Nm 3 / h,Q 酸性气 1060Nm 3 / h,Q 空气 2200Nm 3 / h,C H2S is 0.002, C SO2 is 0.006; K 0 is 2, and the volume correction factor K is 0.87;

[0106] Q 副风变化值 =(Q 酸性气 +Q 空气 )×K×(C H2S -2C SO2 )×2.5=-71.34Nm 3 / h;

[0107] Q 副风新设定值 =Q 副风原设定值 +Q 副风变化值 =28.34Nm 3 / h;

[0108] The new setting value of the auxiliary wind is less than 10% of the auxiliary air range. At this time, the auxiliary air has no ability to control and continue to reduce the air supply. Therefore, keep the auxiliary air unchanged, and calculate the main wind coe...

Embodiment 3

[0116] The difference from Example 1 is that when the acid gas flow rate is constant but the concentration changes, the H 2 S / SO 2 Significant changes in the test results of online testing instruments, SO 2 Concentration 0.6% (mol%), H 2 The concentration of S is 0.2% (mol%); the control module calculates the change of the secondary air according to the formulas I, II, and III, and the flow of the main air is kept at 2120Nm 3 / h,Q 副风原设定值 100Nm 3 / h,Q 酸性气 1060Nm 3 / h,Q 空气 2200Nm 3 / h,C H2S is 0.002, C SO2 is 0.006; K 0 is 2, and the volume correction factor K is 0.87;

[0117] Q 副风变化值 =(Q 酸性气 +Q 空气 )×K×(C H2S -2C SO2 )×2.5=-71.34Nm 3 / h;

[0118] Q 副风新设定值 =Q 副风原设定值 +Q 副风变化值 =28.34Nm 3 / h;

[0119] The new setting value of the auxiliary wind is less than 10% of the auxiliary air range. At this time, the auxiliary air has no ability to control and continue to reduce the air supply. Therefore, keep the auxiliary air unchanged, and calculate the main wind coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com