Material guiding device and production line

A material guide device and material strip technology, applied in the direction of packaging, transportation and packaging, conveyor objects, etc., can solve the problems of manpower and property loss, achieve the effect of ensuring accuracy and convenience, and reducing manpower and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

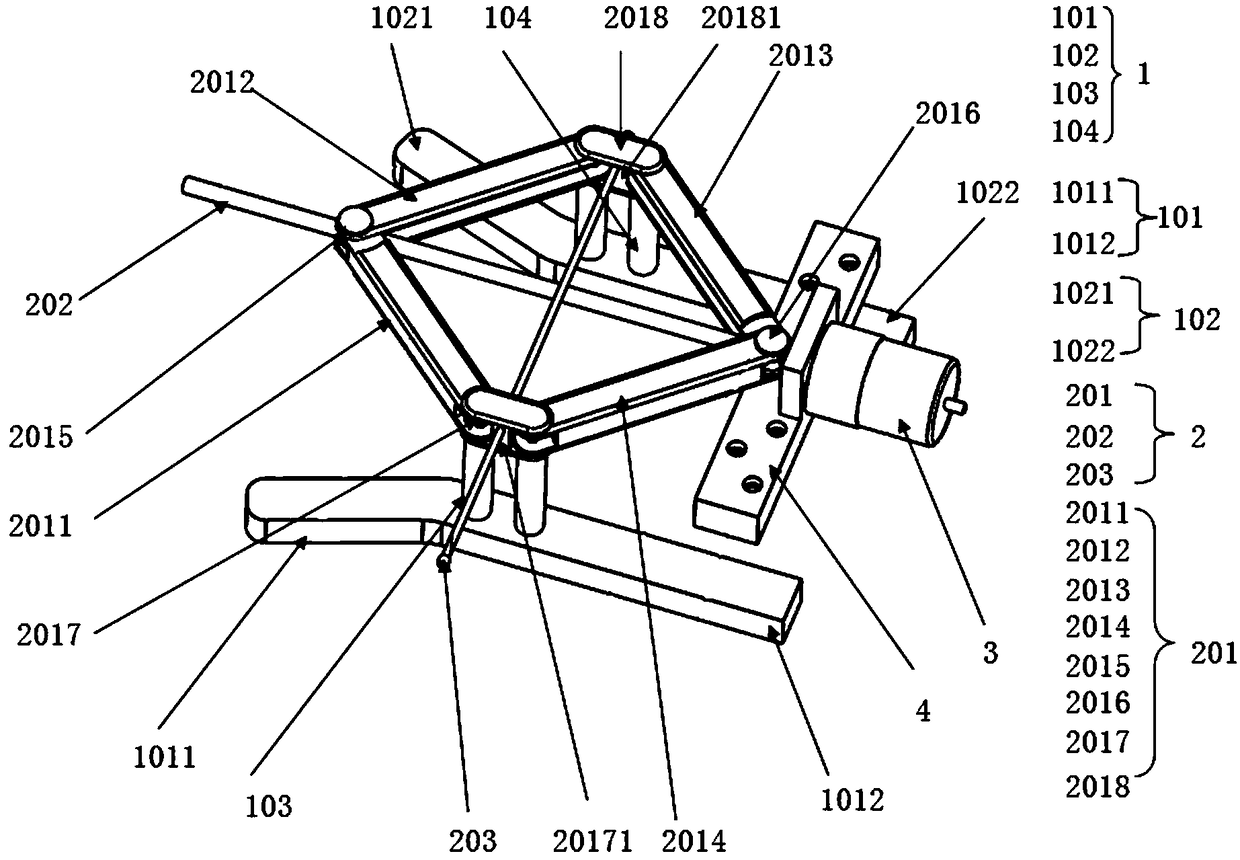

[0063] see figure 1 , a material guiding device, comprising: a guiding unit 1, an adjusting unit 2 and a driving unit 3; the guiding unit 1 is used to adjust the placement order of products on the production line, and the products are adjusted to the same position after passing through the product channel of the guiding unit 1 The adjustment unit 2 is used to adjust the channel size of the product channel to adapt to products of different sizes; the driving unit 3 is used to drive the adjustment unit 2 to adjust the channel size of the product channel.

[0064] In the actual production process of the product, the products or components on the production line are often arranged randomly. In order to carry out automatic production, it is necessary to adjust the randomly placed products to the same arrangement order. The existing material guide device for adjusting the placement order needs to manually adjust the spacing of the material guide blocks according to the size of the p...

Embodiment 2

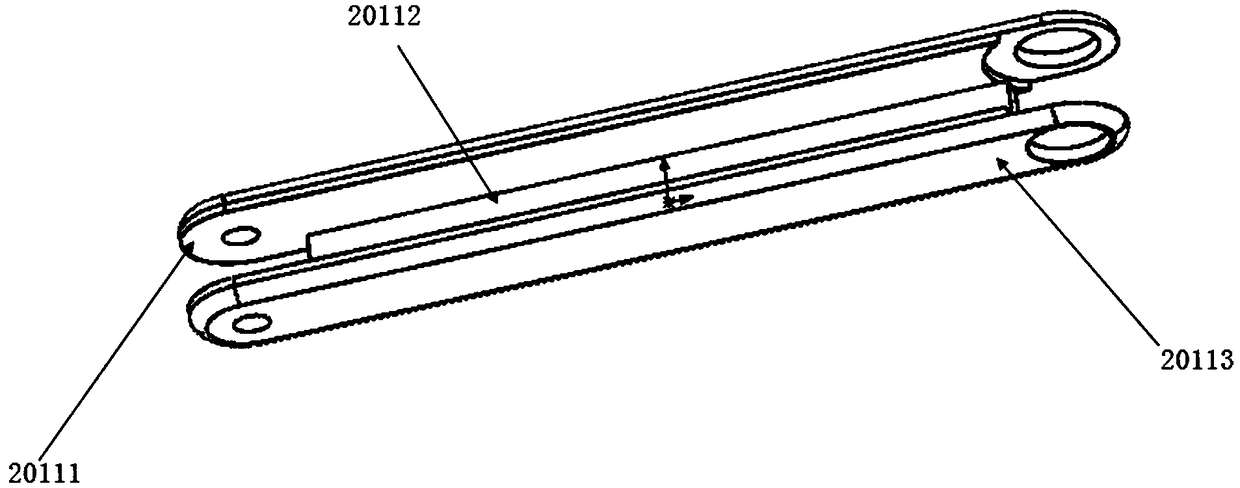

[0069] This embodiment further provides the structural design of the adjustment unit 2 on the basis of the first embodiment. The adjustment unit 2 includes a telescopic structure 201 and an adjustment screw 202; the telescopic structure 201 is a telescopic parallelogram structure, including a first tension arm 2011, a second tension arm 2012, a third tension arm 2013, a fourth tension arm 2014, and a front-end shaft 2015, the rear shaft 2016, the first hinge connector 2017 and the second hinge connector 2018; the two ends of the first tension arm 2011, the two ends of the second tension arm 2012, the two ends of the third tension arm 2013 And both ends of the fourth tension arm 2014 are provided with through holes (see figure 2 as well as image 3 ); the front end rotating shaft 2015 passes through the through hole of the first end of the first tension arm 2011 and the through hole of the first end of the second tension arm 2012, so as to realize the first tension arm 2011 a...

Embodiment approach

[0072] It can be known that a very important structure in the adjustment unit 2 is a structure that converts rotation into linear motion, and in this embodiment, it is realized through the cooperation of the screw and the thread. But it is not limited to this embodiment, for example, the screw pair structure can also convert rotation into linear motion. Therefore, this embodiment can also use the lead screw sub-structure, and those skilled in the art can make adaptive adjustments according to the actual situation, and details will not be repeated here.

[0073] Specifically, the driving unit 3 includes a motor, and the driving part of the motor is connected with the adjusting screw 202 . The driving unit 3 also includes a motor controller, which is used to control the amount of rotation of the motor. Wherein, the motor can be an ordinary motor or a stepping motor.

[0074] Further, the first tension arm 2011, the second tension arm 2012, the third tension arm 2013 and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com