Intelligent AGV carrying forklift with automatic material pushing mechanism

A material pushing mechanism and forklift technology, which is applied in the field of handling forklifts, can solve the problems of reduced cargo storage space, reduced handling efficiency, single fork structure, etc., and achieves the effects of reducing possibility, reducing dumping, and facilitating dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

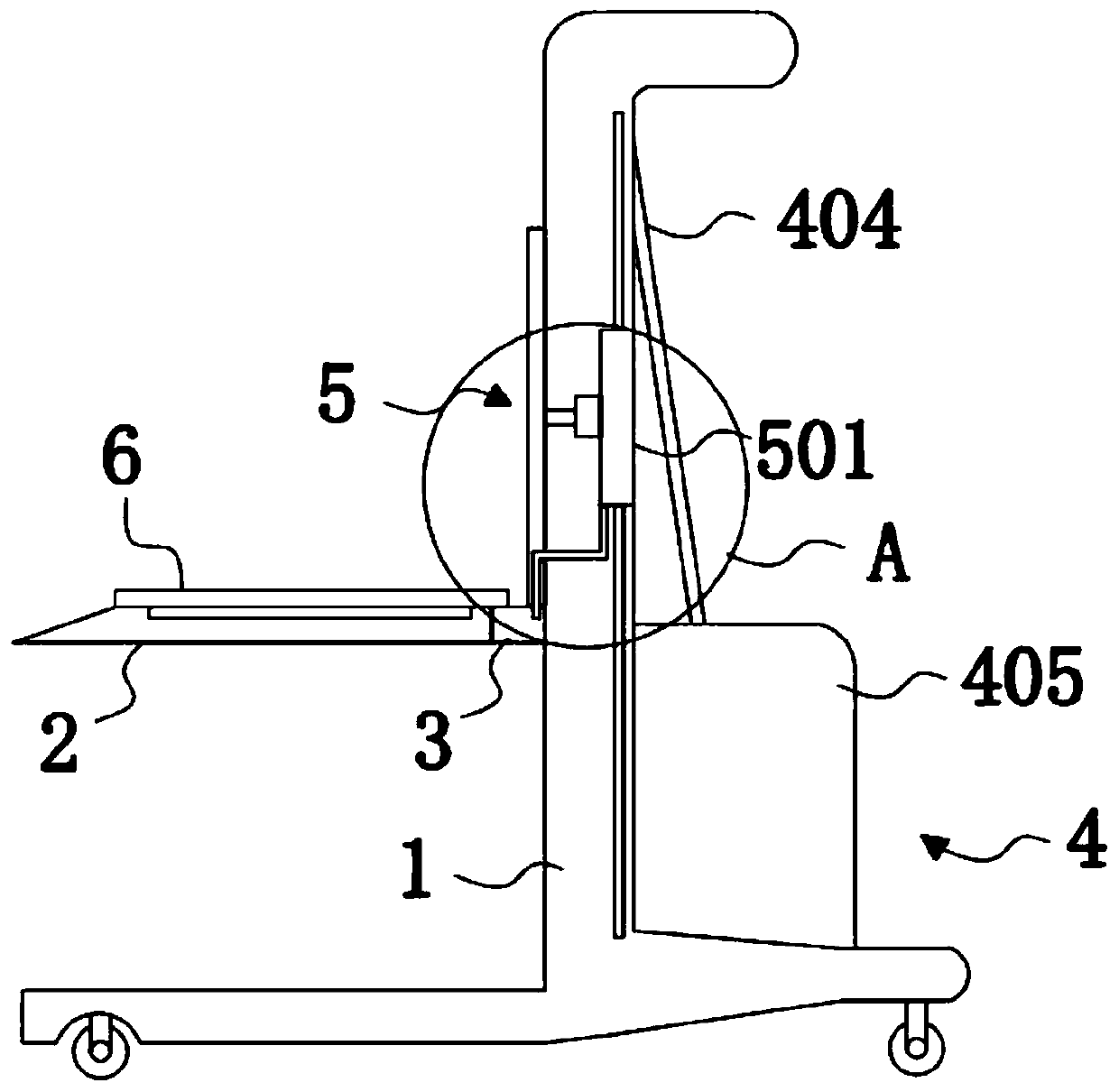

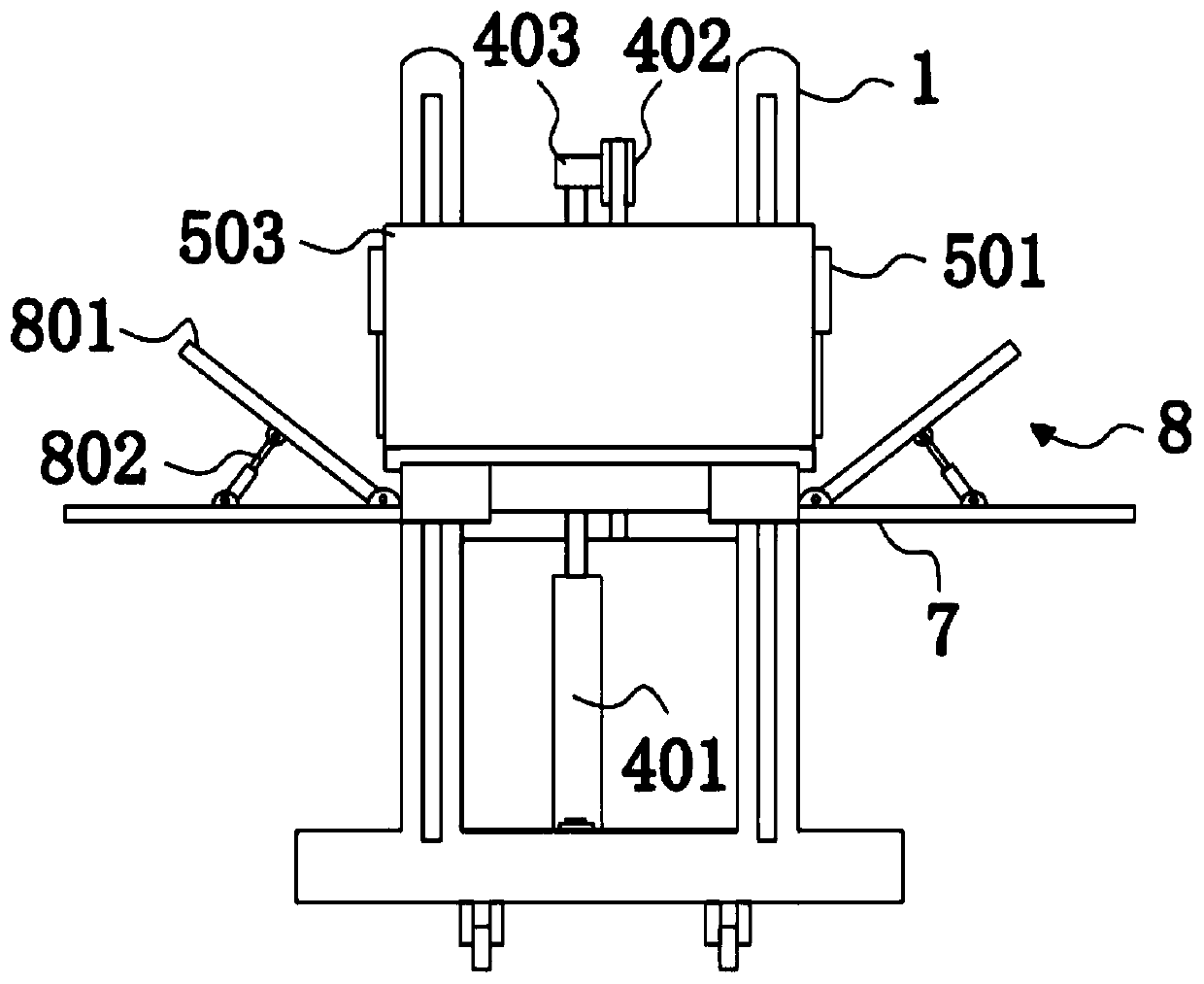

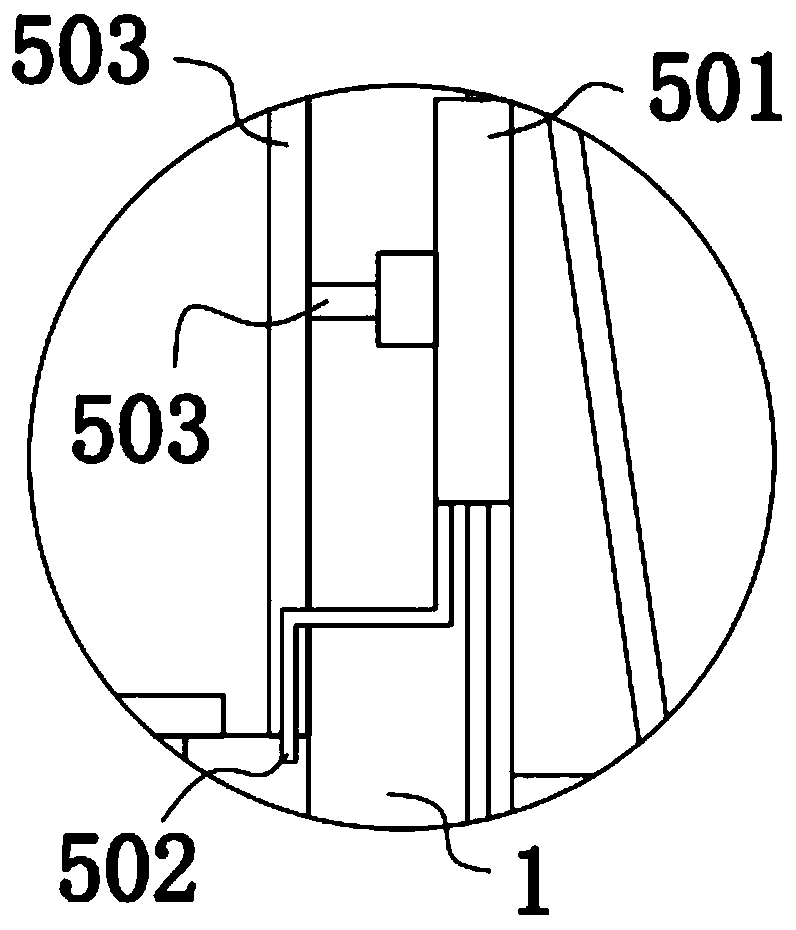

[0024] refer to Figure 1-4 It can be seen that an intelligent AGV handling forklift with an automatic material pushing mechanism in the present invention includes a forklift main body 1 and a fork 2, the front side of the forklift main body 1 slides with a slide plate 3, and the fork 2 is integrated on the slide plate 3 The left and right sides of the front part, and the main body 1 of the forklift is equipped with a drive mechanism 4 that drives the slide plate 3 up and down. The upper part of the slide plate 3 is also integrally equipped with a pusher mechanism 5. A material carrier plate 6 is slidably connected, and side rods 7 are integrally provided on the sides away from the lower sections of the two forks 2, and a material blocking mechanism 8 is installed on the upper part of the side rods 7; the pushing mechanism 5 includes A pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com