All-dimensional detection system and method for automobile shaft component

A detection system and a comprehensive technology, applied in the field of metal parts detection, can solve problems such as low efficiency, inability to guarantee the shooting of shaft parts, and inability to guarantee the reliability of the results, etc., to achieve a large working area, improve the image acquisition effect, facilitate manufacturing and The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

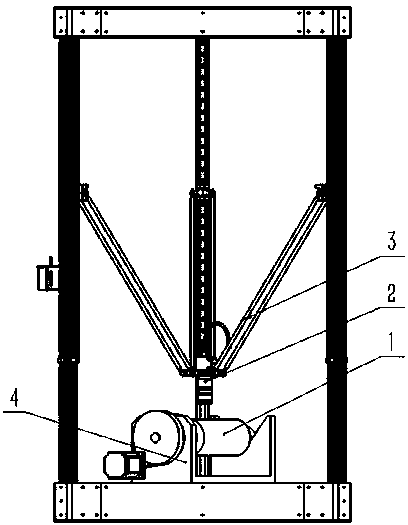

[0024] Such as figure 1 As shown, the omni-directional detection system of a kind of automobile axle parts of the present embodiment comprises: CCD camera 2, camera movement module 3, axle class parts clamping module 4, wherein CCD camera 6 pixel resolutions are 1236 * 1626, frame The data rate is 20fps.

[0025] The omni-directional detection method of a kind of automobile shaft parts of the present embodiment, the main steps include:

[0026] Step 1: The algorithm software module converts the vehicle axle model into STL triangular patch format, and slices the triangular patch by slicing software. Then extract the outer contour of the model after slicing, and calculate the sampling points at equal intervals to the slicing contour line, and calculate the normal direction of the surface where the sampling points are located, the direction of the normal vector is the direction of the CCD camera 2 during detection (when printing the outer contour The external normal vector of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com