Volatile organic compound treatment device and method

A technology for volatile organic compounds and treatment devices, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of substandard waste gas, insufficient, secondary pollution, etc., and reduce treatment costs and production costs. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

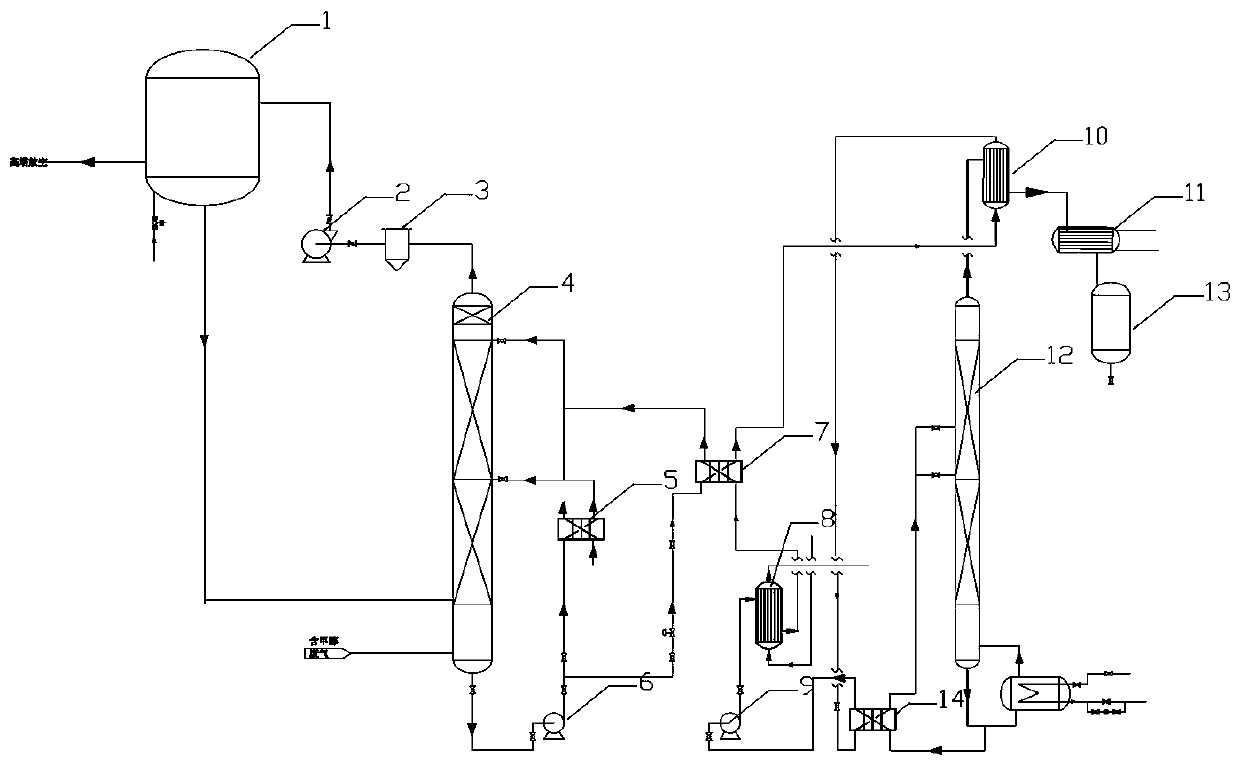

[0038] A volatile organic compound treatment device, including an adsorption tank 1, an induced draft fan 2, a cyclone separator 3, a packed absorption tower 4, a primary condenser 5, a packed tower spray absorption pump 6, a primary preheater 7, and a secondary Condenser 8, rectification tower extraction pump 9, tail gas primary condenser 10, tail gas secondary condenser 11, rectification tower 12, tail gas receiving tank 13, secondary preheater 14, adsorption tank 1 via induced draft fan 2 Connect with the cyclone separator 3, the cyclone separator 3 is connected with the packing absorption tower 4, the filler in the packing absorption tower is high-efficiency activated carbon or high-efficiency molecular sieve; the bottom of the packing absorption tower 4 is sprayed with the absorption pump 6 and the primary The preheater 7 is connected; the primary preheater 7 is connected with the exhaust gas primary condenser 10, and the exhaust gas primary condenser 10 is connected with ...

Embodiment 2

[0041] Taking methanol used for extraction in the production of glycine as an example, add water to the packed absorption tower, control the liquid level of the absorption tower to 0.6m, turn on the spray absorption pump of the packed tower, cool down part of the water in the primary condenser to 10°C for self-circulation, and part of the water The water (enriched liquid) is heated up to 50°C through the first-stage preheater, the first-stage tail gas condenser, and the second-stage preheater to the rectification tower in turn, and the flow rate of the rectification tower is controlled to be 2m 3 / h. Turn on the induced draft fan to pump methanol gas. After the gas is processed by the packed absorption tower and the cyclone separator, it goes to the adsorption tower equipped with activated carbon to absorb and then the high tower is emptied; First use steam to heat up to 100°C for analysis, and then use air to cool down to 26°C for standby. The entire analysis process takes 6 ...

Embodiment 3

[0043] Taking methanol used for extraction in the production of glycine as an example, add water to the packed absorption tower, control the liquid level of the absorption tower to 0.8m, turn on the spray absorption pump of the packed tower, cool down part of the water to the primary condenser to 7°C for self-circulation, and part of the water The water (enriched liquid) is heated up to 55°C through the first-stage preheater, the first-stage tail gas condenser, and the second-stage preheater to the rectification tower in turn, and the flow rate of the rectification tower is controlled to be 3m 3 / h. Turn on the induced draft fan to pump methanol gas. After the gas is processed by the packed absorption tower and the cyclone separator, it goes to the adsorption tower equipped with activated carbon to absorb and then the high tower is emptied; First use steam to heat up to 100°C for analysis, and then use air to cool down to 24°C for standby. The entire analysis process takes 8 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com