Method for removing odor of lutein extract

A technology of lutein and extract, which is applied in the field of refining food additives, can solve the problems of cumbersome operation, lack of reach, and removal of lutein extract, etc., and achieve the effects of simple process, improved purity, and good odor removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix the lutein extract extracted from marigold flowers (the purity is measured by lutein content, and the lutein content in liquid phase detection is 12.1%) and sesame oil at a weight ratio of 1:0.2, and then add it to the molecular distillation equipment , adjust the distillation temperature to 50°C, adjust the vacuum degree to 300Pa, obtain the heavy phase substance after distillation for 1h; add the heavy phase substance to the molecular distillation device, adjust the temperature to 190°C, adjust the vacuum degree to 80Pa, and obtain no The yield of the peculiar smell lutein extract is 99.3%, the purity of the lutein extract is 15.3%, and the chromatographic detection results show that the peak of the peculiar smell substance completely disappears.

Embodiment 2

[0028] Mix the lutein extract extracted from marigold flowers (the purity is measured by the lutein content, and the lutein content in liquid phase detection is 20.3%) and sunflower oil at a ratio of 1:1, and then add it to the molecular distillation equipment , adjust the distillation temperature to 60°C, adjust the vacuum to 200Pa, and obtain the heavy phase substance after distillation for 1.5h; add the heavy phase substance to the molecular distillation device, adjust the temperature to 160°C, adjust the vacuum degree to 5Pa, and obtain after distillation for 1h The lutein extract has no peculiar smell, the content yield is 99.1%, the purity of the lutein extract is 21.2%, and the chromatographic detection results show that the peak of the peculiar smell substance completely disappears.

Embodiment 3

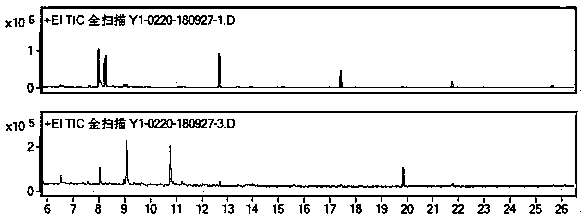

[0030] The lutein extract extracted from marigold flowers (the purity is measured by the lutein content, and the lutein content detected by liquid phase is 15.7%) is mixed with palm oil at a ratio of 1:10 and then added to the molecular distillation equipment. Adjust the distillation temperature to 70°C, adjust the vacuum degree to 400Pa, obtain the heavy phase substance after distillation for 2 hours; add the heavy phase substance to the molecular distillation device, adjust the temperature to 150°C, adjust the vacuum degree to 50Pa, and obtain no The peculiar smell lutein extract has a content yield of 99.2%, and the purity of the lutein extract is 17.6%. Such as figure 1 as shown, figure 1 The waveform diagram at the top is the peak diagram of the odorous substances in the lutein extract, each peak in the figure is the characteristic peak of the odorous substances, and the peak area corresponding to the peak position of the odorous substances in the lower figure is zero, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com