A driving waveform debugging method for eliminating residual heterochromatic particles in the display of a three-color electronic paper module

A technology of driving waveforms and debugging methods, applied in the field of electronic paper, can solve the problems of reducing the user experience of consumers, reducing the contrast of the picture, etc., and achieve the effect of improving the display effect, improving the contrast, and having a good display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

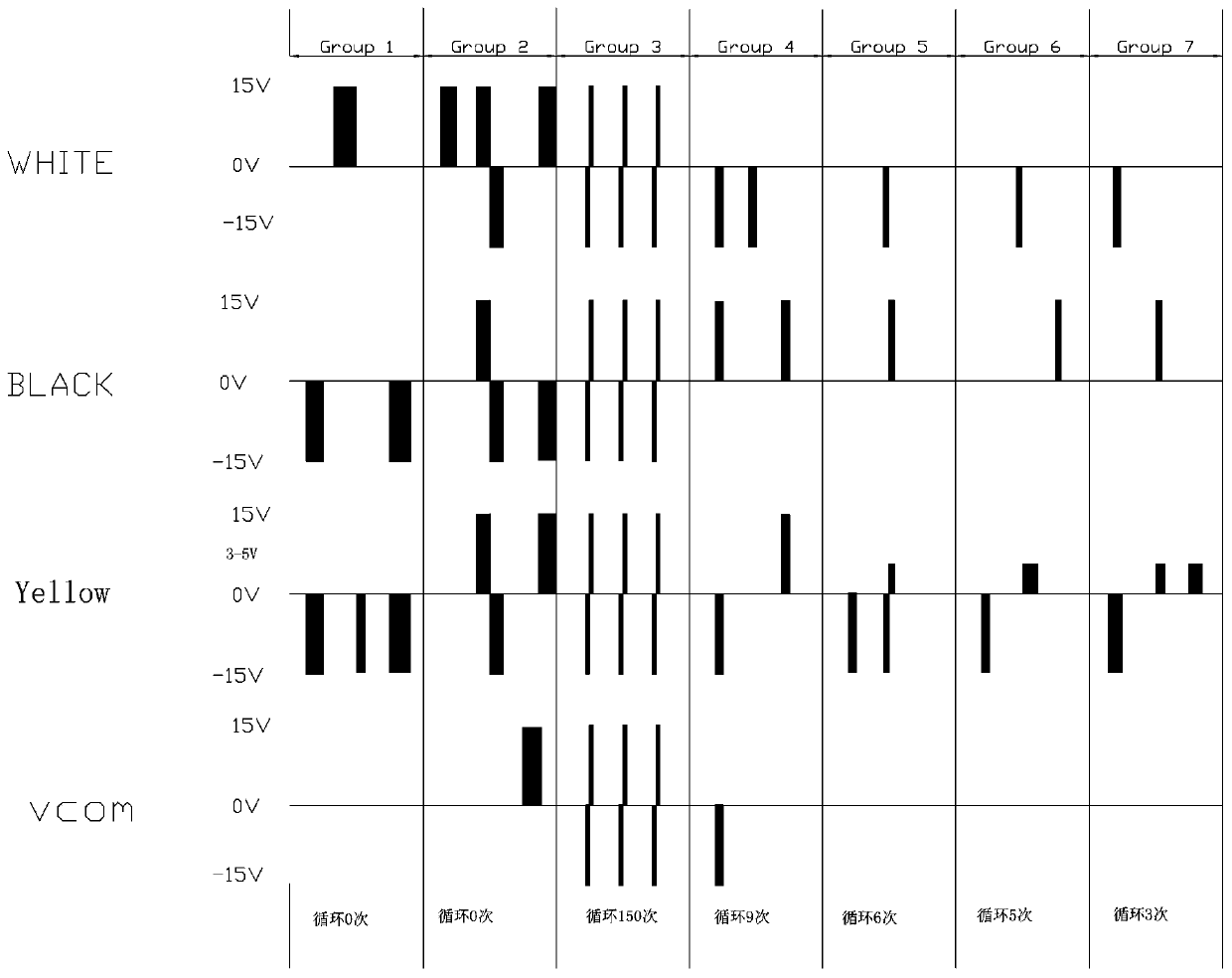

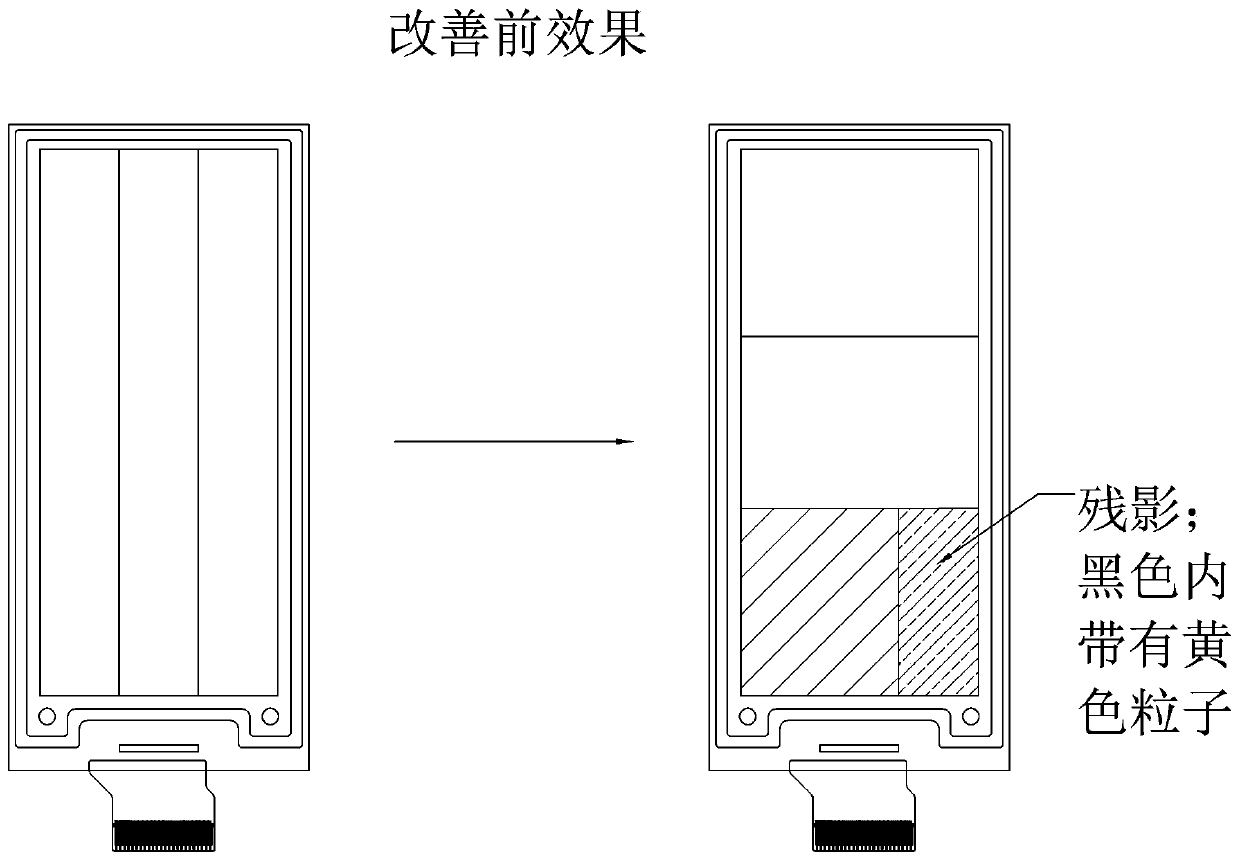

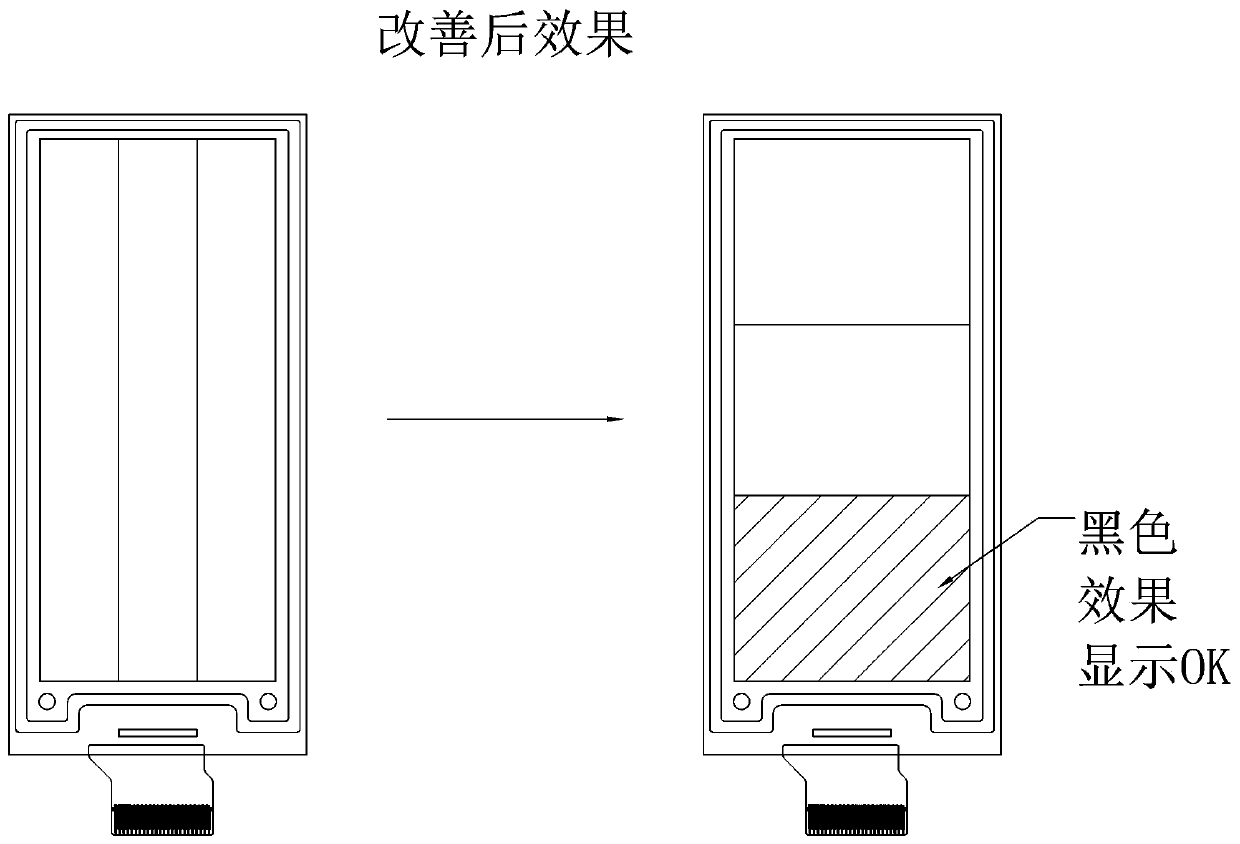

[0027] A driving waveform debugging method for eliminating residual heterochromatic particles in the display of a three-color electronic paper module, such as figure 1 shown, including the following steps:

[0028] (1) Determine the shaking frame area: it is composed of multiple sets of alternating negative and positive high-voltage waveforms with fixed periods, and the display screen is white and black screen flickering; the shaking frame area is composed of 150 sets of alternating negative and positive high-voltage waveforms with fixed periods, a single set The cycle of alternating negative and positive high voltage wavefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com